Complete Guide to Support Components for Frames

By:Admin

With a focus on research and development, Frame Support Components has consistently pushed the boundaries of design and engineering, ensuring that their products meet the highest industry standards. Their team of skilled professionals is dedicated to delivering cutting-edge solutions that offer reliability, durability, and performance.

"Our commitment to excellence and innovation has been the cornerstone of our success," said the spokesperson for Frame Support Components. "We take great pride in our ability to provide our customers with the best support components on the market, and we are constantly striving to exceed their expectations."

The newly launched line of products showcases Frame Support Components' dedication to staying ahead of the curve. The innovative designs and advanced technologies incorporated into these products are a testament to the company's ongoing investment in research and development. Customers can expect enhanced performance, longevity, and ease of use from these new offerings.

In addition to their commitment to quality, Frame Support Components places a strong emphasis on customer satisfaction. The company prides itself on its ability to understand the unique needs of each customer and provide personalized solutions that meet those needs. Their team of knowledgeable professionals is always available to provide expert guidance and support, ensuring that customers are able to make informed decisions.

Frame Support Components' products are designed to cater to a wide range of industries, including automotive, construction, aerospace, and many others. The company's versatile product line is well-suited for various applications, making them a go-to choice for businesses across different sectors.

Furthermore, sustainability is a key consideration for Frame Support Components. The company is committed to minimizing its environmental impact by implementing eco-friendly practices in its operations. From the selection of materials to the manufacturing process, every aspect of the business is carefully managed to ensure that it aligns with the company's sustainability goals.

As part of their customer-focused approach, Frame Support Components offers a comprehensive suite of services to support their products. From technical support to maintenance and repairs, the company is dedicated to ensuring that their customers get the most out of their investment. This commitment to service has been a driving force behind the strong relationships that Frame Support Components has built with its customers over the years.

Looking ahead, Frame Support Components is poised to continue its growth and innovation in the support components industry. The company's ongoing investment in research and development, coupled with its unwavering commitment to quality and customer satisfaction, sets the stage for a promising future.

For more information about Frame Support Components and their latest products, please visit their website or contact their customer service team. With a reputation for excellence and a track record of success, Frame Support Components is a name that customers can trust for all their support component needs.

Company News & Blog

Innovative and Efficient Packing Machine for Papads Unveiled - Latest Updates

Title: Revolutionary Papad Packaging Machine Streamlines Production ProcessIntroduction:In recent years, the food packaging industry has witnessed significant advancements in automation technologies. One such groundbreaking innovation is the Papad Packaging Machine, an efficient and reliable packaging solution designed to streamline the production process. This state-of-the-art machine, manufactured by a leading industry player, promises to revolutionize the way papads are packaged, ensuring higher productivity, superior quality, and enhanced market competitiveness for businesses around the globe.1. Background of Papad Production:Papad, a popular snack in many Asian countries, is made from lentil or chickpea flour. Typically, papads are hand-rolled, sun-dried, and cooked before being packaged for sale. The manual process is time-consuming, labor-intensive, and often prone to inefficiencies leading to compromised hygiene and inconsistent quality. However, with the advent of the Papad Packaging Machine, these challenges are set to become a thing of the past.2. Features and Functionality:The Papad Packaging Machine employs cutting-edge automation technology to produce consistent and commercially packaged papads. Equipped with advanced sensors, pneumatic controls, and a user-friendly interface, this machine minimizes human intervention, ensuring rapid and accurate packaging. From sealing to printing the expiration date and nutritional information, every step in the packaging process is precisely executed to maintain product integrity.3. Enhanced Productivity and Profitability:By automating the papad packaging process, companies can significantly increase their production output and overall profitability. With the introduction of this machine, businesses can eliminate the need for manual labor, reduce human errors, and decrease the time required for each packaging unit. Consequently, manufacturers can sustain higher volumes of production within shorter timeframes, fulfilling customer demands promptly and ensuring consistent product availability in the market.4. Improved Hygiene and Quality Control:The Papad Packaging Machine emphasizes cleanliness and hygiene in the packaging process. Its system, made of stainless steel and other food-grade materials, guarantees that each papad is packaged under optimal conditions. With controlled temperature, humidity, and air quality parameters, this machine ensures better preservation of the product's texture, flavor, and nutritional properties, resulting in superior quality papads reaching the customers' tables.5. Adaptability and Customization:Recognizing the diversity of papad sizes and shapes, the Papad Packaging Machine offers customization options to accommodate various requirements. The machine's flexibility allows it to adapt to a wide range of papad dimensions, enabling businesses to cater to a larger consumer base effectively. Moreover, the ability to incorporate branding elements like logos and graphics on the packaging enhances the product's visibility and marketability.6. Market Competitiveness:With rising competition in the food industry, companies constantly seek innovative solutions to gain a competitive edge. The Papad Packaging Machine offers a game-changing advantage, not only allowing businesses to automate their packaging processes but also enabling them to create a distinct identity in the market. Streamlined production, improved quality, and customization options give manufacturers an opportunity to establish themselves as leaders in the industry and meet the evolving needs of a discerning consumer base.7. Industry Outlook and Global Impact:As worldwide demand for ready-to-eat snacks continues to grow, investing in efficient packaging solutions becomes crucial. The launch of the Papad Packaging Machine provides an opportunity for businesses to streamline their operations, optimize their resources, enter new markets, and meet consumer demands effectively. Furthermore, this innovation demonstrates the capability of the food packaging industry to drive economic growth, promote sustainable practices, and enhance the global food supply chain.Conclusion:The pioneering Papad Packaging Machine represents a significant leap forward in automating the packaging process for papads. Offering improved productivity, superior quality control, and customization options, this cutting-edge machinery empowers businesses to address the challenges of a dynamic market effectively. With its potential to revolutionize the papad industry and set new standards for food packaging, the Papad Packaging Machine promises a prosperous and innovative future for manufacturers, enhancing their competitiveness on a global scale.

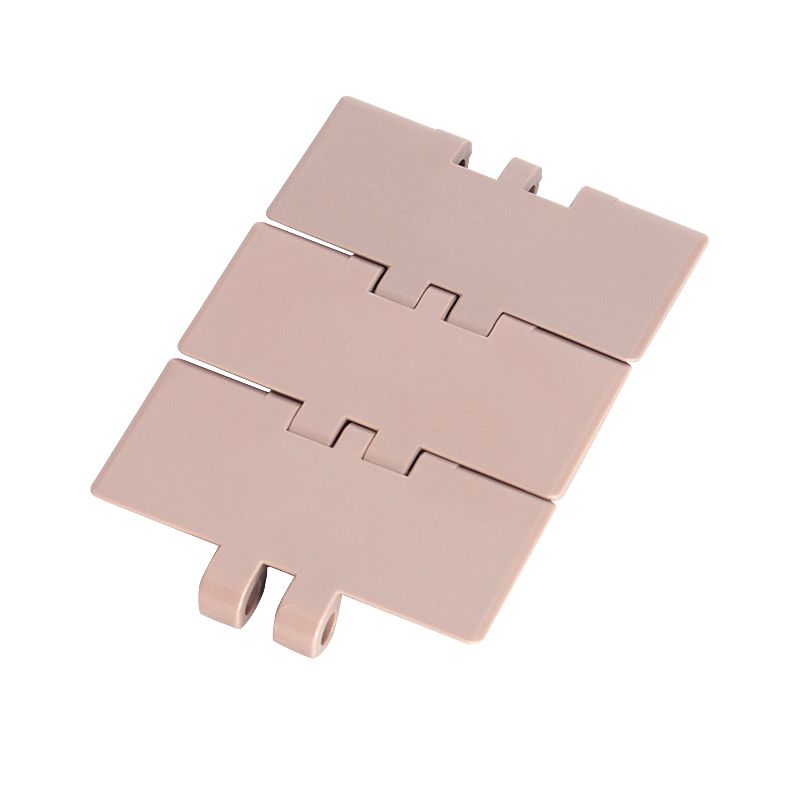

Discover the Benefits of Flush Grid Friction Top Conveyor Belts

In today's world, conveyor belts have become an integral part of the manufacturing process. They ensure that products are transported safely and efficiently from one point to another. Conveyor belt designs have come a long way, incorporating various innovations to meet the specific needs of different industries.One such innovation in the conveyor belt industry is the flush grid friction top design. This unique design is gaining popularity due to its numerous benefits, which are helping industries to automate their operations, reduce downtime, increase production, and enhance product quality, among others.Flush grid friction top belts have a series of evenly spaced openings arranged in a grid pattern on the belt's surface. This design gives the conveyor belt an excellent grip on the products being transported, preventing slippage, and ensuring that the products maintain their position on the conveyor belt. The openings in the flush grid design also allow for easy and thorough cleaning, making it ideal for the food and beverage industry, where hygiene is paramount.One company that is at the forefront of designing and manufacturing flush grid friction top belts is {} (). The company has been in the conveyor belt industry for over 40 years, and its experience and expertise enable it to create high-quality conveyor belts that meet the varying needs of different industries.{} () offers a range of flush grid friction top belts that are tailored to the specific requirements of each industry. Their belts are versatile and suitable for various industries, including food and beverage, pharmaceutical, automotive, and electronics, among others. The company's flush grid friction top belts are made from high-quality materials that are durable and resistant to wear and tear, ensuring they have a long lifespan, reducing the need for frequent replacements.In addition to manufacturing flush grid friction top belts, {} () also provides customization services. The company can design and manufacture conveyor belts that meet the unique needs of their clients. They can tailor the belt's width, length, thickness, and surface pattern, among other specifications, depending on the client's requirements.One of the features that set {} () apart from other conveyor belt manufacturers is their commitment to quality and customer satisfaction. The company has invested in state-of-the-art equipment and employs a team of experienced professionals who ensure that each belt that leaves their facilities meets the company's high standards. They also offer excellent customer service, providing technical support and advice to clients, ensuring they make an informed decision when selecting a conveyor belt.The flush grid friction top design has numerous benefits that are revolutionizing the conveyor belt industry. Industries that have adopted this design have noticed a significant improvement in their production processes, resulting in increased efficiency, reduced downtime, and enhanced product quality.In conclusion, {} () is a leading manufacturer of flush grid friction top conveyor belts, providing high-quality products that meet the diverse needs of different industries. Their commitment to excellence and customer satisfaction makes them the ideal partner for industries seeking to optimize their production processes. With their expertise and state-of-the-art equipment, {} () is poised to continue leading the industry in innovation and exceptional service delivery.

Guide to Connecting Joints for Improved Mobility and Flexibility

Connecting Joints, a leading manufacturer of joint technology and solutions, has been at the forefront of developing innovative products for a wide range of industries. With a commitment to quality, reliability, and customer satisfaction, Connecting Joints has established itself as a trusted partner for businesses around the world.The company's extensive product line includes a variety of joints and connectors designed to meet the diverse needs of its customers. From standard to custom solutions, Connecting Joints offers a range of products to support various applications, including automotive, aerospace, construction, and more. With a focus on precision engineering and advanced manufacturing processes, the company is able to deliver high-performance solutions that meet the highest industry standards.Connecting Joints takes pride in its ability to provide tailored solutions that address the specific challenges of its customers. By working closely with clients to understand their unique requirements, the company is able to develop custom joint solutions that optimize performance, efficiency, and cost-effectiveness. This collaborative approach has earned Connecting Joints a reputation for delivering cutting-edge solutions that drive success for its clients.In addition to its innovative products, Connecting Joints is known for its dedication to excellence in customer service. The company's team of experienced professionals is committed to providing responsive support and technical expertise to help customers make informed decisions about their joint technology needs. Whether it's assisting with product selection, offering guidance on installation and maintenance, or providing ongoing support, Connecting Joints is there every step of the way to ensure customer satisfaction.As a global leader in joint technology, Connecting Joints has built a strong reputation for its commitment to quality and reliability. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that its products consistently meet the highest standards of performance and durability. With a focus on continuous improvement and innovation, Connecting Joints is always exploring new technologies and methodologies to push the boundaries of what is possible in joint engineering.Moreover, Connecting Joints places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its environmental footprint by employing eco-friendly manufacturing practices and materials. By prioritizing sustainable solutions, Connecting Joints aims to contribute to a greener and more sustainable future for the industries it serves.Looking ahead, Connecting Joints is poised to continue its legacy of excellence in joint technology and solutions. The company remains committed to driving innovation, delivering exceptional products, and providing unparalleled customer service. By staying true to its core values and leveraging its expertise, Connecting Joints is well-positioned to meet the evolving needs of its customers and maintain its leadership in the industry.In conclusion, Connecting Joints has established itself as a trusted and innovative provider of joint technology and solutions. With a focus on quality, reliability, and customer satisfaction, the company has earned a strong reputation as a leader in the industry. Through its commitment to excellence, sustainability, and customer service, Connecting Joints continues to set the standard for joint engineering and remains a valued partner for businesses worldwide.

High-speed Meal Tray Sealing Machine for Fresh Food Packaging

ABC Company Introduces Innovative Meal Tray Sealing MachineABC Company, a leading provider of food packaging solutions, has recently introduced an innovative Meal Tray Sealing Machine that is set to revolutionize the food packaging industry. This state-of-the-art machine is designed to meet the growing demand for efficient and hygienic food packaging solutions, and is expected to offer significant benefits to food businesses and consumers alike.The Meal Tray Sealing Machine is equipped with advanced technology and features that ensure airtight sealing of food trays, maintaining the freshness and quality of the packaged food. The machine is capable of sealing a wide range of tray sizes and shapes, making it highly versatile for different food packaging requirements. This is especially crucial for businesses that offer a variety of meal options, as the machine can accommodate the diverse needs of the food industry.One of the key advantages of the Meal Tray Sealing Machine is its ability to enhance the shelf life of the packaged food. By sealing the trays in an airtight manner, the machine helps to prevent contamination and extend the freshness of the food, reducing food waste and ensuring that consumers receive high-quality products. This is particularly important for businesses that distribute pre-packaged meals or ready-to-eat food items, as it allows them to maintain the integrity of their products for a longer period of time.In addition to extending shelf life, the Meal Tray Sealing Machine also offers remarkable efficiency and cost savings for food businesses. With its high-speed sealing capabilities, the machine can significantly increase the production output and streamline the packaging process, reducing the time and labor required for packaging operations. This is a major advantage for businesses looking to improve their operational efficiency and reduce packaging costs, as the machine offers a cost-effective solution for high-volume food packaging needs.Furthermore, the Meal Tray Sealing Machine is designed with food safety and hygiene in mind, ensuring that the packaged food remains uncontaminated throughout the packaging process. The machine is equipped with sanitation features that maintain strict hygiene standards, minimizing the risk of bacterial contamination and ensuring that the food remains safe for consumption. This is especially important in light of increasing concerns about food safety and hygiene, as the machine provides reassurance to consumers that the packaged food meets the highest standards of quality and cleanliness.The introduction of the Meal Tray Sealing Machine is a testament to ABC Company’s commitment to innovation and excellence in food packaging solutions. With a strong focus on meeting the evolving needs of the food industry, ABC Company has consistently delivered cutting-edge packaging technologies that offer tangible benefits to businesses and consumers. The Meal Tray Sealing Machine is a continuation of this tradition, providing a reliable and efficient solution for food businesses seeking to enhance their packaging capabilities and deliver superior products to the market.As the food industry continues to evolve and adapt to changing consumer preferences and market dynamics, the demand for innovative packaging solutions is expected to grow. The Meal Tray Sealing Machine represents a significant advancement in food packaging technology, offering a versatile, efficient, and hygienic solution that addresses the key challenges faced by food businesses. With its potential to improve shelf life, increase efficiency, and ensure food safety, the machine is poised to make a substantial impact on the industry and set a new standard for food packaging excellence.In conclusion, the introduction of the Meal Tray Sealing Machine by ABC Company marks a significant milestone in the advancement of food packaging technology. With its impressive features and benefits, the machine is set to redefine the standards for food packaging efficiency, quality, and hygiene, offering a compelling solution for businesses seeking to enhance their packaging capabilities. As the industry continues to embrace innovation and progress, the Meal Tray Sealing Machine is poised to play a crucial role in shaping the future of food packaging, delivering value to businesses and consumers alike.

How to Choose the Best Shrink Wrap Machine for Food Packaging

Food Shrink Wrap Machine Revolutionizes Packaging IndustryInnovative technology has always been at the forefront of the packaging industry, constantly driving change and improvement. One such technological marvel is the Food Shrink Wrap Machine, a groundbreaking solution that has revolutionized the way food is packaged and preserved.Developed by a leading packaging solutions provider, this state-of-the-art machine has been hailed as a game-changer for the food industry. With its advanced features and unparalleled efficiency, it has quickly gained popularity among food manufacturers and distributors worldwide.The Food Shrink Wrap Machine employs a process called shrink wrapping to package food products securely and efficiently. This technique involves using a specially designed film that, when heated, shrinks tightly around the product, creating a protective seal. The result is a neatly sealed package that not only safeguards the food but also enhances its shelf life.One of the most significant advantages of the Food Shrink Wrap Machine is its ability to accommodate a wide range of food products. From fresh produce to processed meats, dairy products, and even bakery items, this versatile machine can shrink wrap virtually any type of food with precision and accuracy. This flexibility makes it an indispensable tool for manufacturers and distributors who deal with a diverse range of food items.The machine's efficient performance is another key factor that sets it apart. With its automated processes and cutting-edge technology, it can package food items at a remarkably fast pace, improving productivity and reducing labor costs. Additionally, the Food Shrink Wrap Machine's precise temperature control ensures that the film shrinks uniformly around the product, guaranteeing a professional and visually appealing finish every time.Furthermore, the Food Shrink Wrap Machine is designed with convenience in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and operate the machine with minimal training. Its compact size also allows it to fit seamlessly into existing production lines, minimizing disruptions and maximizing workflow efficiency.In addition to its exceptional performance, the Food Shrink Wrap Machine prioritizes food safety. The machine's film is composed of food-grade materials that comply with strict industry standards. This ensures that the packaged food remains contaminant-free and maintains its freshness and quality.The advantages of the Food Shrink Wrap Machine extend beyond packaging efficiency. Its innovative design and sustainable features make it an eco-friendly solution, aligning with the growing demand for sustainable packaging practices. The machine's film is recyclable, reducing waste and minimizing its environmental footprint. Additionally, the efficient use of energy and resources contributes to a greener, more sustainable packaging process.Recognizing the immense potential of this cutting-edge technology, food manufacturers and distributors around the world have started embracing the Food Shrink Wrap Machine. Its ability to enhance product presentation, extend shelf life, and improve overall efficiency has led to increased profitability for businesses.The Food Shrink Wrap Machine has truly transformed the packaging industry. Through its unmatched precision, speed, and versatility, it has become an integral part of the food manufacturing process. As the demand for efficient and sustainable packaging solutions continues to rise, the Food Shrink Wrap Machine stands at the forefront, revolutionizing the way food is packaged and delivered to consumers around the globe.

Top 5 Benefits of Corrugated Roofing Sheets for Your Home

[Company Introduction] Founded in {year}, {company name} is a leading provider of high-quality building materials, specializing in corrugated roofing sheets. With a strong focus on innovation and customer satisfaction, {company name} has established itself as a trusted partner for both residential and commercial construction projects. Our commitment to excellence and reliability has earned us a solid reputation in the industry, making us the go-to choice for contractors, architects, and homeowners alike.[News Content] Corrugated Roofing Sheets have become increasingly popular in the construction industry due to their durability, affordability, and aesthetic appeal. These versatile sheets are widely used for roofing, siding, and fencing applications, offering a range of benefits that make them a preferred choice for various projects.One of the key advantages of corrugated roofing sheets is their exceptional durability. Made from high-quality materials, these sheets are designed to withstand harsh weather conditions, including heavy rain, snow, and strong winds. This makes them an ideal choice for areas prone to extreme weather, providing long-term protection for buildings and structures.Additionally, corrugated roofing sheets are known for their ease of installation. Their lightweight design and flexible nature allow for quick and efficient installation, reducing labor costs and construction time. This makes them an attractive option for contractors and builders looking to streamline the building process while maintaining high standards of quality.Furthermore, corrugated roofing sheets are available in a variety of colors and finishes, allowing for customization to suit specific design preferences. Whether it's a modern, sleek look or a more rustic, traditional aesthetic, these sheets can be tailored to enhance the overall appearance of a building. This versatility makes them a popular choice for both residential and commercial projects, offering a wide range of creative possibilities.In addition to their aesthetic appeal and durability, corrugated roofing sheets are also an environmentally friendly option. Many of the materials used in their production are recyclable, making them a sustainable choice for eco-conscious builders and property owners. This aligns with {company name}'s commitment to environmental responsibility, as we continuously seek ways to minimize our ecological footprint while delivering top-tier products.As a leading provider of corrugated roofing sheets, {company name} is dedicated to offering an extensive selection of high-quality products to meet the diverse needs of our customers. Our state-of-the-art manufacturing facilities and stringent quality control processes ensure that every sheet meets the highest standards of performance and reliability.With a focus on innovation, {company name} continues to explore new technologies and materials to further enhance the functionality and aesthetics of our corrugated roofing sheets. Our team of highly skilled engineers and designers are dedicated to pushing the boundaries of what is possible, ensuring that our products remain at the forefront of the industry.In conclusion, corrugated roofing sheets are a versatile, durable, and aesthetically pleasing option for a wide range of construction projects. As a trusted provider of high-quality building materials, {company name} is proud to offer a comprehensive range of corrugated roofing sheets that meet the highest standards of performance, reliability, and sustainability. With a commitment to excellence and customer satisfaction, {company name} remains a preferred partner for builders, contractors, and homeowners seeking top-tier solutions for their construction needs.

Discover the Convenience and Durability of Plastic Caps for Box Sections

Plastic Caps for Box Section: Ensuring Safe and Secure Packaging SolutionsIn today's fast-paced world, packaging plays a crucial role in preserving the quality and integrity of products during transportation and storage. As various industries continue to evolve, so do the packaging solutions required to meet their specific needs. One such solution that has gained significant attention is the use of plastic caps for box sections.Plastic caps for box sections, often made of high-density polyethylene (HDPE), are designed to cover and protect the ends of box sections. These caps create a secure barrier, preventing dust, moisture, and other contaminants from entering and potentially damaging the contents. They ensure that the shipped products remain intact and reach their destination in pristine condition.As the demand for efficient and sustainable packaging solutions rises, more companies are turning to plastic caps for box sections due to their numerous benefits. Let's explore the advantages of using these caps and how they contribute to a safer and more secure packaging process.Protection: Box sections are widely used in industries such as construction, automotive, and furniture manufacturing, where the components are often prone to damage without proper care. Plastic caps act as a protective shield, safeguarding the exposed ends from impact, scratches, and abrasions. This helps in minimizing potential losses and reducing the need for costly replacements.Secure sealing: The snug fit provided by plastic caps ensures that the box sections are securely closed, preventing any accidental openings during handling or transport. This feature is especially important when shipping delicate or valuable products, as it minimizes the risk of theft or damage.Durability: Plastic caps made from HDPE are renowned for their durability and resistance to environmental factors such as UV rays, extreme temperatures, and moisture. This robustness prolongs the lifespan of the caps, allowing for multiple uses and reducing the overall packaging costs.Versatility: Plastic caps for box sections are available in various shapes and sizes to accommodate different dimensions and applications. They can be easily customized to fit specific box section sizes, offering a flexible solution for diverse packaging requirements.Efficiency: By using plastic caps, companies can streamline their packaging process. These caps are lightweight and easy to handle, allowing for swift sealing and unsealing of box sections. Additionally, their universal design enables quick identification and retrieval of products, saving valuable time in warehouses or storage facilities.Sustainability: As the world becomes increasingly conscious of environmental issues, sustainable packaging solutions have become paramount. Plastic caps for box sections, made from recyclable materials, align with the principles of sustainable packaging. Additionally, their durability reduces the need for single-use alternatives, contributing to waste reduction.Leading the Industry: One company at the forefront of providing top-quality plastic caps for box sections is {}. With decades of experience in the packaging industry, they have established themselves as a trusted supplier of innovative solutions. Their range of plastic caps caters to a broad spectrum of industries, ensuring the safe handling and transportation of their products.Located in {}, {} consistently delivers high-quality products backed by a commitment to customer satisfaction. Working closely with their clients, they understand the unique packaging needs of different industries and provide customized solutions designed to meet specific requirements.The company's dedication to quality is evident in their manufacturing process, where they utilize state-of-the-art technology to ensure precise measurements and superior product performance. Their strict quality control measures guarantee that each plastic cap adheres to the highest standards of durability and protection.Furthermore, {} emphasizes sustainability by using eco-friendly materials and minimizing waste in their operations. They strive to contribute to a greener future by encouraging the use of recyclable packaging materials.In conclusion, plastic caps for box sections have emerged as a reliable solution for ensuring safe and secure packaging. With their ability to protect, seal, and provide durability, these caps are the go-to choice for industries seeking efficient and sustainable packaging solutions. With companies like {} leading the way, businesses can rest assured knowing their products are in good hands.

Discover the Thrilling Experience of Sightseeing from a Flat Top Base Flight

Flat Top Base Flight: The Ultimate Way to Experience the OutdoorsFlat Top Base Flight, the leading provider of powered paragliding (PPG) equipment and training, is revolutionizing the way outdoor enthusiasts experience the world. By combining the thrill of free-flight with the convenience of a motorized engine, Flat Top Base Flight enables people to soar above breathtaking landscapes with ease and freedom.Founded in 2005 by Jeff Goin, a world-renowned expert in the PPG field, the company has quickly become the go-to source for PPG aficionados. With a deep commitment to safety, quality, and customer satisfaction, Flat Top Base Flight offers a wide range of products and services, including PPG courses, equipment sales and rentals, repairs and maintenance, and online resources.Whether you're a seasoned pilot or a curious beginner, Flat Top Base Flight has something for you. Their flagship product, the Flat Top Ninja, is widely regarded as the best paramotor on the market, thanks to its unparalleled stability, power, and versatility. Designed and manufactured in the USA, the Flat Top Ninja combines cutting-edge technology with years of field testing and customer feedback to deliver the ultimate PPG experience.But Flat Top Base Flight is much more than just a paramotor dealer. Their team of experienced instructors and technicians is dedicated to helping you grow your skills and confidence as a PPG pilot, no matter where you are in your journey. From personalized training programs to ongoing support and mentoring, Flat Top Base Flight is committed to empowering you to explore the world from a new perspective.What sets Flat Top Base Flight apart from other PPG providers is their unwavering focus on safety. Jeff Goin, who has written several books on PPG safety and accident prevention, has made it his mission to promote responsible flying and education within the PPG community. As a result, Flat Top Base Flight has developed a comprehensive safety program that covers everything from equipment selection and maintenance to weather awareness and emergency procedures.Furthermore, Flat Top Base Flight is a strong advocate for environmental conservation and sustainability. They recognize the importance of preserving the natural beauty of our planet and strive to minimize their carbon footprint and environmental impact. In addition, they support various environmental organizations and initiatives that promote conservation and awareness.Whether you're looking to fly over majestic mountains, soar above endless deserts, or glide along the coastline, Flat Top Base Flight has the equipment, expertise, and passion to make it happen. With locations all around the country, including a headquarters in Utah and a training center in Florida, Flat Top Base Flight is accessible to anyone who desires to experience the freedom of flight.In conclusion, Flat Top Base Flight is more than just a PPG company; it's a community of passionate adventurers who share a common love for nature, flight, and exploration. With their innovative products, top-notch training, and unwavering commitment to safety and sustainability, Flat Top Base Flight is leading the way in the world of powered paragliding.

High-Quality Variable Speed Belt for All Your Machinery Needs

Bando Variable Speed Belt, a Leading Innovator in Power Transmission SolutionsWith a commitment to innovation and excellence, {company name} has established itself as a leader in providing power transmission solutions for a wide range of industries. The company's dedication to quality and reliability has made it a trusted partner for businesses around the world.One of {company name}'s flagship products is the Bando Variable Speed Belt, which has set a new benchmark for performance and durability in power transmission. The Bando Variable Speed Belt is designed to deliver optimal power transmission in a wide range of industrial applications, providing businesses with the reliability and efficiency they need to keep their operations running smoothly.The Bando Variable Speed Belt is engineered to deliver exceptional performance in variable speed drives, making it a versatile solution for a variety of applications. Its advanced design allows for smooth and efficient power transmission, while its durable construction ensures long-lasting performance even in the most demanding environments.One of the key features of the Bando Variable Speed Belt is its ability to adapt to changing speed and load conditions, providing businesses with the flexibility they need to optimize their operations. Whether it's in manufacturing, agriculture, construction, or any other industry, the Bando Variable Speed Belt is equipped to handle the challenges of variable speed drives, delivering consistent performance and reliability.In addition to its exceptional performance, the Bando Variable Speed Belt is also designed with maintenance in mind. Its reliable and durable construction minimizes the need for frequent maintenance, reducing downtime and increasing overall productivity for businesses. This means that businesses can rely on the Bando Variable Speed Belt to keep their operations running smoothly, without the hassle of frequent maintenance and repairs.{company name} has a long-standing reputation for providing high-quality power transmission solutions, and the Bando Variable Speed Belt is a testament to that commitment. With its innovative design, exceptional performance, and durability, the Bando Variable Speed Belt has earned its place as a trusted choice for businesses seeking reliable power transmission solutions.In conclusion, {company name} is proud to offer the Bando Variable Speed Belt as part of its comprehensive range of power transmission solutions. With its exceptional performance, durability, and versatility, the Bando Variable Speed Belt is a testament to the company's commitment to innovation and excellence. Businesses around the world can rely on {company name} and the Bando Variable Speed Belt to meet their power transmission needs, and to keep their operations running smoothly and efficiently.

Profile Steel: A Versatile Building Material for Construction Projects

Z Profile Steel is an innovative construction material that has been making waves in the industry due to its strength, durability, and versatility. This steel, which is used in a variety of construction projects, is known for its ability to withstand heavy loads and extreme weather conditions. With the growing demand for sustainable and high-performance construction materials, Z Profile Steel has become a popular choice for architects, engineers, and construction professionals.The company behind Z Profile Steel is committed to providing high-quality and reliable steel products to its customers. With a focus on research and development, the company has continuously improved its steel production process to ensure that Z Profile Steel meets and exceeds industry standards. In addition to its dedication to quality, the company also places a strong emphasis on sustainability and environmental responsibility. The steel production process is carefully managed to minimize waste and reduce its carbon footprint, making Z Profile Steel an eco-friendly choice for construction projects.One of the key advantages of Z Profile Steel is its versatility. This steel can be used in a wide range of construction applications, from residential buildings to commercial and industrial projects. Its strength and durability make it suitable for supporting heavy loads, making it an ideal choice for beams, columns, and other structural elements. Moreover, Z Profile Steel can be easily customized to fit the specific requirements of a project, allowing for greater design flexibility and creativity.In addition to its strength and versatility, Z Profile Steel also offers significant cost benefits. Its long lifespan and low maintenance requirements make it a cost-effective choice for construction projects. Furthermore, the company behind Z Profile Steel offers a range of value-added services to its customers, including technical support, design assistance, and project management. This level of support ensures that customers get the most out of Z Profile Steel and can complete their projects with confidence.The popularity of Z Profile Steel has been steadily growing, and it has been used in a number of high-profile construction projects around the world. From skyscrapers to bridges, this steel has proven its worth in some of the most demanding and iconic structures. Its ability to withstand extreme conditions and support heavy loads has made it a go-to choice for architects and engineers who are looking for a reliable and high-performance construction material.Looking ahead, the company behind Z Profile Steel is poised for further growth and success. With a strong commitment to quality, sustainability, and customer satisfaction, the company is well-positioned to meet the increasing demand for Z Profile Steel in the construction industry. As the industry continues to prioritize innovation and performance, Z Profile Steel is expected to play a key role in shaping the future of construction.In conclusion, Z Profile Steel is a highly versatile and reliable construction material that has gained widespread recognition for its strength, durability, and cost-effectiveness. With a strong focus on quality, sustainability, and customer support, the company behind Z Profile Steel has positioned itself as a leader in the industry. As the demand for high-performance and sustainable construction materials continues to grow, Z Profile Steel is well-equipped to meet the needs of the industry and contribute to the development of exceptional structures around the world.