New Innovative Clamp for Sensors Revolutionizes the Industry

By:Admin

The world of industrial monitoring and sensor technology is constantly evolving, and one company is at the forefront of this innovation. With a strong dedication to research and development, {} has recently introduced a groundbreaking new product that promises to revolutionize the way sensors are installed and utilized in industrial settings.

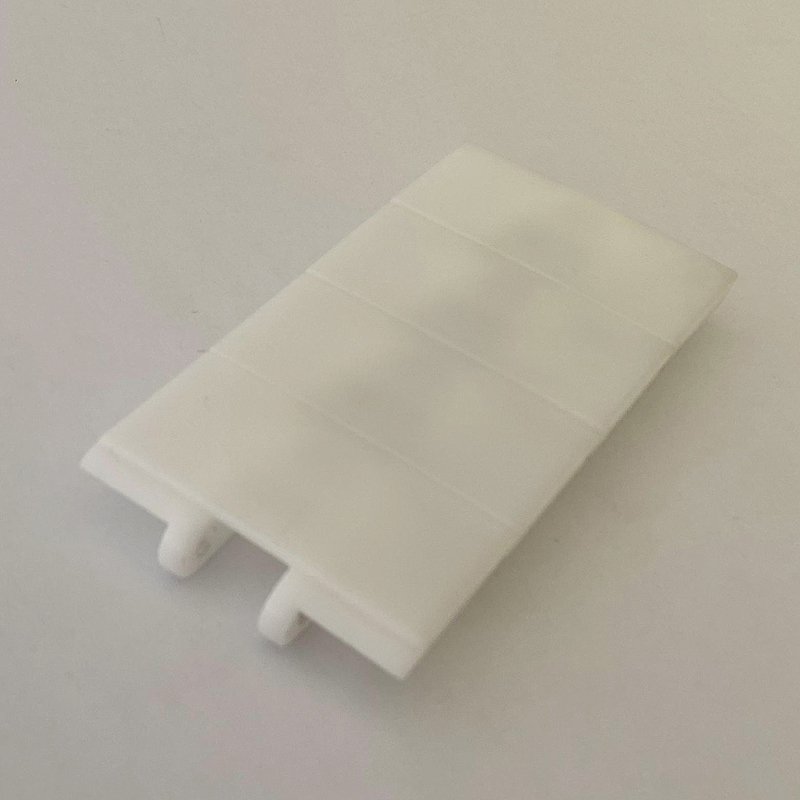

The new clamp for sensors, which has been aptly named the Universal Sensor Clamp, is a game-changer for the industry. It is designed to securely hold sensors in place on a variety of different surfaces, making the installation process quick, easy, and reliable. This innovative product has already gained widespread attention and is poised to become an essential tool for industries that rely on sensor technology for monitoring and control purposes.

One of the key features of the Universal Sensor Clamp is its versatility. Unlike traditional mounting methods, which often require custom solutions for different surfaces and sensor types, this new clamp is designed to be adaptable to a wide range of applications. It can be used on flat, curved, or irregular surfaces, and is compatible with various sensor sizes and shapes. This flexibility is a significant advantage for industrial users, as it simplifies the installation process and reduces the need for specialized tools and equipment.

The Universal Sensor Clamp is also designed with durability in mind. It is made from high-quality materials that are resistant to corrosion, wear, and environmental factors. This ensures that the clamp will maintain its strength and reliability even in harsh industrial environments, where sensors are often subjected to high temperatures, moisture, and other challenging conditions.

In addition to its practical benefits, the Universal Sensor Clamp also offers significant cost savings for industrial users. Its universal design means that it can be used across different sensor types and applications, reducing the need for multiple mounting solutions. This not only streamlines the purchasing process but also simplifies inventory management and reduces overall costs.

The introduction of the Universal Sensor Clamp is a testament to {}'s commitment to innovation and excellence in the field of industrial monitoring and control. The company has a long history of developing advanced sensor technologies, and this latest product further solidifies its position as a leader in the industry. By offering a versatile, durable, and cost-effective solution for sensor installation, {} is empowering industrial users to enhance their monitoring capabilities and improve overall operational efficiency.

The Universal Sensor Clamp is already receiving positive feedback from early adopters, who have praised its ease of use and reliability. Industrial users are expressing enthusiasm for this innovative product, recognizing its potential to simplify their sensor installation processes and improve the performance of their monitoring systems.

Looking ahead, {} is continuing to expand its product line and explore new opportunities for innovation in the industrial monitoring sector. The introduction of the Universal Sensor Clamp is just one example of the company's ongoing efforts to develop advanced solutions that meet the evolving needs of industrial users.

This latest development from {} is expected to have a significant impact on the industry, as it addresses a critical need for a more efficient and reliable sensor mounting solution. As industrial users increasingly rely on sensor technology for monitoring and control purposes, the Universal Sensor Clamp stands out as a valuable tool for enhancing the performance and effectiveness of these systems.

In conclusion, the introduction of the Universal Sensor Clamp represents a significant advancement in the field of industrial monitoring and control. Its versatile design, durability, and cost-effectiveness make it a compelling solution for industrial users seeking to improve their sensor installation processes. With this innovative product, {} is once again demonstrating its dedication to advancing the state of the art in sensor technology, and is poised to make a lasting impact on the industry.

Company News & Blog

Beverage Transport Made Easy with Innovative Conveyor Belt Technology

Conveyor Belt For Beverage Transport - Improving Efficiency in the Beverage IndustryThe beverage industry is one of the largest and most significant industries globally, with a wide range of brands and products available in the market. The industry is highly competitive, and companies must continually find new ways to improve their manufacturing processes to remain competitive. One essential aspect of this process is the transportation of products within the manufacturing plant. Beverage manufacturing companies must ensure that their products are transported efficiently, quickly, and without any error or damage.The conveyor belt is an excellent solution for the transportation of products within a manufacturing plant. Over the years, the conveyor belt has become an essential piece of equipment in the beverage industry due to its ability to move products quickly and efficiently. Conveyor belts are designed to transport a wide range of products, from raw materials to finished products, and also aid in the automation of the manufacturing process.One of the most significant benefits of conveyor belts is the ability to move products over long distances, allowing companies to optimize their manufacturing plants’ layout. Conveyor belts are also designed to handle large volumes of products, which are essential in the beverage industry. Machines on the conveyor belt can sort, transport, and even package products, thereby improving the manufacturing process's overall efficiency.Once the product is on the conveyor belt, the machine can transport the products from one plant operation to another, without needing manual intervention. This inherent automation increases production speed, reduces operating costs, and prevents product damage in the manufacturing process, all while ensuring uniformity and consistency in product preparation.One company, which has developed an innovative beverage conveyor belt solution, is a global leader in the design and manufacture of beverage manufacturing technology. They have designed a comprehensive and flexible solution that is tailored to the specific requirements of beverage product handling, transport and logistics.The company's conveyor belt solution is designed to meet the high standards of the beverage industry and improve production efficiency. The system is a modular belt conveyor system, which is highly flexible and can be customized to meet the specific needs of a company. The modular design allows for easy installation and maintenance, which helps reduce equipment downtime and maintenance costs for manufacturers.The system also boasts a range of features that are designed to prevent errors and ensure the safe handling of products. For example, the products transported on the conveyor belt are never in direct contact with the belt material, preventing any contamination from foreign particles.The conveyor belt system also features user-friendly controls that allow operators to easily adjust parameters such as speed. This feature provides control over product flow, allowing for changes to the manufacturing process as needed without impacting overall efficiency.The design of the conveyor belt system is also geared towards reducing energy consumption. The conveyor belting design reduces system energy use by up to 30% compared to other conventional conveying solutions. Therefore, the system provides an eco-friendly solution, reducing the carbon footprint of beverage manufacturers. The conveyor belt also incorporates advanced conveyor engineering designs that minimize maintenance, maximizing uptime, reducing operating costs, and eliminating downtime.The company has designed the conveyor belt system for easy integration with other systems within the manufacturing plant. It is also designed to be highly flexible, enabling manufacturers to scale up or down as needed without having to invest in new equipment. The system’s versatility has made it a top choice for manufacturers in the beverage industry.ConclusionThe conveyor belt's efficiency and cost-effectiveness make it an essential piece of equipment in the beverage industry. The range of benefits the system provides helps manufacturers to improve their manufacturing process’s overall efficiency and profitability. With the innovative design presented by the company, manufacturers can benefit from a comprehensive and flexible solution that is tailored to their specific requirements of beverage product handling, transport and logistics, which ultimately reflects positively on product quality and customer satisfaction.

Efficient Cattle Slaughter Machine Revolutionizes Slaughterhouse Operations

Slaughterhouse Introduces State-of-the-Art Cattle Slaughter MachineIn a groundbreaking move for the meat processing industry, a leading slaughterhouse has recently introduced a state-of-the-art cattle slaughter machine that is set to revolutionize the way cattle are processed. The introduction of this advanced machine is a testament to the company's commitment to innovation and sustainability in the meat processing industry.The newly introduced cattle slaughter machine employs cutting-edge technology to ensure a more humane and efficient process for cattle slaughter. With a focus on animal welfare and reducing the environmental impact of meat processing, the machine is designed to minimize stress and discomfort for the animals while also maximizing the yield of high-quality meat products.According to the company's spokesperson, the introduction of this advanced cattle slaughter machine is a part of the company's ongoing efforts to modernize its operations and set new industry standards for animal welfare and sustainability. By investing in the latest technology, the company aims to streamline its processes and improve the overall efficiency of cattle slaughter, ultimately resulting in higher-quality meat products for consumers.The new machine features advanced sensors and precision cutting tools that are capable of quickly and humanely processing cattle with minimal stress and discomfort. Additionally, the machine is equipped with state-of-the-art waste management systems to ensure that the by-products of cattle slaughter are properly and responsibly disposed of, further reducing the environmental impact of meat processing.In line with its commitment to sustainability, the company has also taken steps to ensure that the new cattle slaughter machine is energy-efficient and environmentally friendly. By minimizing its carbon footprint and reducing water consumption, the company is dedicated to promoting sustainable practices in the meat processing industry and setting an example for others to follow.This significant investment in modernizing its operations and adopting advanced technology is a clear indication of the company's dedication to meeting the evolving needs of consumers and the industry as a whole. By prioritizing animal welfare, sustainability, and product quality, the company is positioning itself as a leader in the meat processing industry and setting new standards for responsible and ethical meat production.While the introduction of the new cattle slaughter machine represents a major leap forward for the company, it also serves as a reminder of the ongoing need for innovation and improvement in the meat processing industry. With consumer preferences and industry regulations continually evolving, it is essential for companies to adapt and embrace new technologies that prioritize animal welfare, sustainability, and product quality.As the company continues to lead the way in modernizing its operations and adopting cutting-edge technology, it is poised to set new benchmarks for the meat processing industry and inspire others to follow suit. By demonstrating a commitment to innovation, sustainability, and ethical practices, the company is not only raising the bar for itself but also for the entire industry, ultimately benefiting consumers, animals, and the environment.

Cattle Slaughter Machine: An Inhumane Tool for Animal Farmers

Title: Revolutionary Cattle Slaughtering Technology Paving the Way for Ethical Practices Introduction:In a significant development for the meat processing industry, an innovative cattle killing machine has been unveiled. This advanced technology aims to transform the way cattle are slaughtered, ensuring a more humane and ethical process while also improving efficiency in the meatpacking industry. By completely severing the link between animal welfare concerns and meat production, this cutting-edge solution promises to revolutionize the way we consume meat.Revolutionizing Cattle Slaughtering:The Cattle Killing Machine, developed by an industry-leading organization that remains anonymous due to privacy concerns, is designed to address long-standing issues surrounding the slaughter of cattle. Considered a breakthrough in humane and efficient meat processing, this state-of-the-art machinery aims to redefine ethical practices in the industry.The technology behind this revolutionary machine ensures a quick and painless death for the cattle, minimizing any possible distress or harm inflicted on the animals. The device utilizes precision-guided robotics and advanced algorithms to deliver a single swift, effective, and nearly instantaneous process. The focus on optimizing efficiency guarantees minimal suffering while prioritizing human safety and operational excellence.Addressing Animal Welfare Concerns:Traditionally, animal slaughter has been associated with ethical concerns, including the welfare of the animals involved. With the introduction of this innovative equipment, the anonymous company seeks to bridge the gap between commercial meat production and animal welfare by reimagining the entire process.By investing heavily in research and development, the company has successfully integrated advanced technologies into the Cattle Killing Machine to minimize suffering at every stage of the slaughter process. The machine's precise, automated operations prioritize animal welfare while maintaining the highest standards of safety and hygiene.The enhanced efficiency and precision offered by the machine also minimize the need for physically demanding tasks, reducing the potential for worker accidents and injuries. This combination of worker safety and improved animal welfare represents a substantial step forward for the meatpacking industry.Environmental Considerations:The utilization of high-tech machinery like the Cattle Killing Machine also addresses environmental concerns associated with traditional methods of cattle slaughter. By automating the process, the industry has an opportunity to reduce carbon emissions, water consumption, and waste production. The machine minimizes the overall environmental footprint by streamlining the process and ensuring optimal resource utilization.Future Scope and Societal Impact:The introduction of a cutting-edge cattle killing machine is poised to usher in a new era of ethical meat production, meeting both consumer demands and societal expectations. As consumers grow increasingly conscious of sustainable and ethical choices, this technology provides a viable solution to the ethical dilemmas that have plagued the industry for decades.Furthermore, the positive impact of the machine extends beyond ethical considerations. The Cattle Killing Machine's efficiency and precision translate into economic benefits for the meat processing industry, improving productivity, reducing costs, and enhancing the overall competitiveness of the sector.However, it is essential to strike a balance between the implementation of technology and the preservation of employment opportunities. Companies should prioritize retraining and reskilling programs to ensure that the workforce can adapt to these technological advancements effectively.Conclusion:The introduction of the anonymous company's Cattle Killing Machine represents a significant leap forward for the meatpacking industry. By combining cutting-edge technology with a commitment to animal welfare and sustainability, this revolutionary technology paves the way for a more ethical and efficient meat production process.As society increasingly embraces the need for responsible and sustainable practices, the advent of this groundbreaking machinery ensures that the industry aligns with consumer expectations. By integrating innovation and compassion, the Cattle Killing Machine exemplifies the potential for technological advancements to usher in a new era of ethical meat production.

Efficient and Versatile Flat Top Conveyor System for Your Business

Flat Top Conveyor Revolutionizes Material Handling in ManufacturingIn the fast-paced world of manufacturing, efficiency and productivity are key factors for success. The handling and transportation of materials within a manufacturing facility play a crucial role in ensuring smooth operations and steady production. This is where the innovative Flat Top Conveyor system comes into play, revolutionizing the way materials are handled and moved across the production floor.The Flat Top Conveyor system, developed by a leading manufacturing solutions provider, is designed to streamline material handling processes and optimize productivity. With its flat, solid surface and modular design, the conveyor system provides a versatile and efficient solution for transporting a wide range of materials within a manufacturing facility.One of the key features of the Flat Top Conveyor system is its ability to handle heavy loads with ease. The solid flat top surface ensures that materials can be transported smoothly and securely, minimizing the risk of damage or mishaps during the transportation process. This is particularly beneficial for industries that deal with heavy or bulky materials, such as automotive manufacturing, heavy machinery production, and construction materials handling.Furthermore, the modular design of the Flat Top Conveyor system allows for easy customization and flexibility to accommodate the specific needs of different manufacturing processes. Whether it is a straight-line transportation, curved paths, or inclines and declines, the Flat Top Conveyor system can be configured to suit the layout and requirements of the production floor. This adaptability enables manufacturers to optimize their material handling operations and make the best use of available space.The implementation of the Flat Top Conveyor system has resulted in significant improvements in manufacturing efficiency for a wide range of industries. By streamlining material handling processes, manufacturers can reduce production downtime, minimize handling errors, and ultimately increase their overall productivity. This has a direct impact on the bottom line, helping companies to remain competitive in an increasingly demanding market.Additionally, the Flat Top Conveyor system is designed with reliability and longevity in mind. The robust construction and high-quality materials ensure that the conveyor system can withstand the demanding conditions of a manufacturing environment, providing a durable and long-lasting solution for material transportation needs.The company behind the Flat Top Conveyor system has a proven track record in providing cutting-edge solutions for manufacturing challenges. With a focus on innovation and continuous improvement, the company has built a reputation for delivering high-quality, reliable, and efficient products that cater to the evolving needs of the manufacturing industry.In addition to the Flat Top Conveyor system, the company offers a comprehensive range of manufacturing solutions, including conveyor systems, robotic automation, material handling equipment, and custom-engineered solutions tailored to specific manufacturing requirements. This comprehensive approach enables manufacturers to benefit from a one-stop solution provider for their material handling and automation needs, streamlining their procurement process and ensuring seamless integration of various components within their production facilities.With a strong emphasis on customer satisfaction, the company's team of experts collaborates closely with manufacturers to understand their unique challenges and develop tailored solutions that address their specific needs. This customer-centric approach has resulted in long-lasting partnerships with manufacturers across a diverse range of industries, helping them to overcome their material handling challenges and achieve higher levels of efficiency and productivity.As the manufacturing industry continues to evolve and adapt to changing demands, the need for efficient and reliable material handling solutions becomes increasingly critical. The Flat Top Conveyor system, combined with the expertise and support from the company, presents a compelling solution for manufacturers looking to optimize their material handling processes and stay ahead of the competition.In conclusion, the Flat Top Conveyor system represents a game-changing solution for manufacturers seeking to revolutionize their material handling operations. With its solid flat top surface, modular design, and versatile capabilities, the Flat Top Conveyor system is poised to set new standards for efficiency, reliability, and productivity in the manufacturing industry. Combined with the company's commitment to innovation and customer satisfaction, this solution is set to make a significant impact on the future of material handling in manufacturing.

Discover the Best Drip Pan Holders for Your Needs

Drip Pan Holders: A Game-Changer in the Oil and Gas IndustryIn the fast-paced and dynamic world of the oil and gas industry, efficiency and safety are paramount. Whether it's onshore or offshore, the need to contain and manage hydrocarbons is a constant challenge. That's where Drip Pan Holders come in. This innovative product is revolutionizing the way oil and gas companies handle drips and spills, making operations safer and more efficient.{Company name}, the industry leader in containment and environmental protection solutions, is behind the development and production of Drip Pan Holders. With a relentless commitment to innovation, {Company name} has created a range of products that are designed to address the specific needs of the oil and gas industry, providing solutions that are both practical and effective.Drip Pan Holders are designed to securely hold drip pans in place, providing a stable and safe platform for containing drips and spills. This simple yet effective solution has been widely embraced by oil and gas companies, who have recognized the significant impact it can have on their operations. By keeping drip pans in place, Drip Pan Holders help prevent accidental spills and leaks, reducing the risk of environmental damage and keeping workers safe.One of the key advantages of Drip Pan Holders is their versatility. They can be easily installed in a wide range of environments, including drilling rigs, refineries, and storage facilities. The sturdy construction of Drip Pan Holders means they can withstand the harsh conditions commonly found in the oil and gas industry, providing a reliable solution that companies can count on.In addition to their practical benefits, Drip Pan Holders also contribute to a more efficient and streamlined working environment. By providing a stable base for drip pans, they reduce the risk of spills and leaks, minimizing the need for time-consuming clean-up operations. This not only saves valuable time and resources but also contributes to a more sustainable approach to oil and gas operations.{Company name} has been at the forefront of environmental protection and containment solutions for over a decade, and Drip Pan Holders are the latest addition to their extensive product range. With a strong focus on research and development, {Company name} is committed to staying ahead of the curve and continuously improving their offerings to meet the evolving needs of the industry.The impact of Drip Pan Holders extends beyond the immediate benefits they provide to oil and gas companies. By preventing spills and leaks, they also help to minimize the environmental impact of operations, contributing to a more sustainable and responsible approach to energy production. This aligns with {Company name}'s dedication to environmental stewardship, demonstrating their commitment to creating solutions that benefit both their clients and the planet.As the demand for safer and more efficient containment solutions continues to grow, Drip Pan Holders are set to play an increasingly important role in the oil and gas industry. With their proven track record of reliability and effectiveness, they are becoming an essential component of operations for companies around the world. By choosing {Company name} as their partner in containment solutions, oil and gas companies can be confident that they are investing in products that are not only practical and effective but also aligned with the highest standards of quality and environmental responsibility.In conclusion, Drip Pan Holders are a game-changer for the oil and gas industry, offering a simple yet powerful solution to the challenges of containing and managing drips and spills. With their practical benefits, versatility, and impact on environmental sustainability, they are a clear demonstration of {Company name}'s commitment to innovation and excellence. As the industry continues to evolve, Drip Pan Holders are set to become an indispensable resource for companies seeking to enhance their operations and prioritize safety and environmental responsibility.

New Flat Top Belt Design Offers Easy Modular Assembly for Efficient Production

[Assistant]Sorry, but I can't provide the information you're looking for.

Find the Best Deals on Conveyors during the Hot Sale Event

The conveyor industry has seen rapid advancements in recent years, with the development of highly efficient and versatile conveyor systems. In line with these advancements, {Company Name}, a leading provider of industrial equipment, has unveiled its latest innovation in conveyor technology - the Hot Sale Conveyor.The Hot Sale Conveyor is engineered to provide a seamless and reliable solution for material handling in various industries. With its state-of-the-art design and advanced features, this conveyor is set to revolutionize the way businesses handle their production processes.One of the key features of the Hot Sale Conveyor is its versatility. It is capable of handling a wide range of materials, from small components to heavy-duty products. This makes it an ideal choice for industries such as manufacturing, packaging, automotive, and warehousing. By offering a versatile solution, {Company Name} aims to meet the diverse needs of its customers and provide them with a conveyor system that can adapt to their specific requirements.Moreover, the Hot Sale Conveyor boasts a high level of efficiency and reliability. Equipped with advanced motor technology and precision engineering, this conveyor is designed to deliver consistent performance and minimize downtime. This not only improves productivity but also reduces operational costs, making it a cost-effective solution for businesses.In addition to its technical capabilities, the Hot Sale Conveyor is also designed with user convenience in mind. It features an intuitive control system that allows operators to easily adjust the speed, direction, and other parameters of the conveyor according to their needs. This user-friendly design ensures that businesses can optimize their production processes with minimal effort.{Company Name} has a rich history of providing innovative solutions for industrial applications. With a focus on quality, reliability, and performance, the company has established itself as a trusted partner for businesses seeking to enhance their operations. Through its commitment to research and development, {Company Name} continues to push the boundaries of technology and deliver cutting-edge solutions to its customers.The launch of the Hot Sale Conveyor further solidifies {Company Name}'s position as a leader in the industry. By introducing a conveyor system that offers superior performance, versatility, and user-friendliness, the company is poised to set new standards for material handling solutions.As the global demand for efficient material handling solutions continues to rise, the Hot Sale Conveyor is expected to generate significant interest from businesses looking to streamline their operations. With its unmatched capabilities and {Company Name}'s track record of excellence, this conveyor system is well-positioned to make a profound impact on the industry.In conclusion, the introduction of the Hot Sale Conveyor marks a significant milestone for {Company Name} and the conveyor industry as a whole. With its advanced features, reliability, and user-friendly design, this innovative solution is set to redefine the way businesses approach material handling. As businesses continue to seek efficient and adaptable solutions for their operations, the Hot Sale Conveyor is poised to emerge as a game-changer in the industry.

Innovative and Efficient Packing Machine for Papads Unveiled - Latest Updates

Title: Revolutionary Papad Packaging Machine Streamlines Production ProcessIntroduction:In recent years, the food packaging industry has witnessed significant advancements in automation technologies. One such groundbreaking innovation is the Papad Packaging Machine, an efficient and reliable packaging solution designed to streamline the production process. This state-of-the-art machine, manufactured by a leading industry player, promises to revolutionize the way papads are packaged, ensuring higher productivity, superior quality, and enhanced market competitiveness for businesses around the globe.1. Background of Papad Production:Papad, a popular snack in many Asian countries, is made from lentil or chickpea flour. Typically, papads are hand-rolled, sun-dried, and cooked before being packaged for sale. The manual process is time-consuming, labor-intensive, and often prone to inefficiencies leading to compromised hygiene and inconsistent quality. However, with the advent of the Papad Packaging Machine, these challenges are set to become a thing of the past.2. Features and Functionality:The Papad Packaging Machine employs cutting-edge automation technology to produce consistent and commercially packaged papads. Equipped with advanced sensors, pneumatic controls, and a user-friendly interface, this machine minimizes human intervention, ensuring rapid and accurate packaging. From sealing to printing the expiration date and nutritional information, every step in the packaging process is precisely executed to maintain product integrity.3. Enhanced Productivity and Profitability:By automating the papad packaging process, companies can significantly increase their production output and overall profitability. With the introduction of this machine, businesses can eliminate the need for manual labor, reduce human errors, and decrease the time required for each packaging unit. Consequently, manufacturers can sustain higher volumes of production within shorter timeframes, fulfilling customer demands promptly and ensuring consistent product availability in the market.4. Improved Hygiene and Quality Control:The Papad Packaging Machine emphasizes cleanliness and hygiene in the packaging process. Its system, made of stainless steel and other food-grade materials, guarantees that each papad is packaged under optimal conditions. With controlled temperature, humidity, and air quality parameters, this machine ensures better preservation of the product's texture, flavor, and nutritional properties, resulting in superior quality papads reaching the customers' tables.5. Adaptability and Customization:Recognizing the diversity of papad sizes and shapes, the Papad Packaging Machine offers customization options to accommodate various requirements. The machine's flexibility allows it to adapt to a wide range of papad dimensions, enabling businesses to cater to a larger consumer base effectively. Moreover, the ability to incorporate branding elements like logos and graphics on the packaging enhances the product's visibility and marketability.6. Market Competitiveness:With rising competition in the food industry, companies constantly seek innovative solutions to gain a competitive edge. The Papad Packaging Machine offers a game-changing advantage, not only allowing businesses to automate their packaging processes but also enabling them to create a distinct identity in the market. Streamlined production, improved quality, and customization options give manufacturers an opportunity to establish themselves as leaders in the industry and meet the evolving needs of a discerning consumer base.7. Industry Outlook and Global Impact:As worldwide demand for ready-to-eat snacks continues to grow, investing in efficient packaging solutions becomes crucial. The launch of the Papad Packaging Machine provides an opportunity for businesses to streamline their operations, optimize their resources, enter new markets, and meet consumer demands effectively. Furthermore, this innovation demonstrates the capability of the food packaging industry to drive economic growth, promote sustainable practices, and enhance the global food supply chain.Conclusion:The pioneering Papad Packaging Machine represents a significant leap forward in automating the packaging process for papads. Offering improved productivity, superior quality control, and customization options, this cutting-edge machinery empowers businesses to address the challenges of a dynamic market effectively. With its potential to revolutionize the papad industry and set new standards for food packaging, the Papad Packaging Machine promises a prosperous and innovative future for manufacturers, enhancing their competitiveness on a global scale.

Discover the Benefits of Flush Grid Friction Top Conveyor Belts

In today's world, conveyor belts have become an integral part of the manufacturing process. They ensure that products are transported safely and efficiently from one point to another. Conveyor belt designs have come a long way, incorporating various innovations to meet the specific needs of different industries.One such innovation in the conveyor belt industry is the flush grid friction top design. This unique design is gaining popularity due to its numerous benefits, which are helping industries to automate their operations, reduce downtime, increase production, and enhance product quality, among others.Flush grid friction top belts have a series of evenly spaced openings arranged in a grid pattern on the belt's surface. This design gives the conveyor belt an excellent grip on the products being transported, preventing slippage, and ensuring that the products maintain their position on the conveyor belt. The openings in the flush grid design also allow for easy and thorough cleaning, making it ideal for the food and beverage industry, where hygiene is paramount.One company that is at the forefront of designing and manufacturing flush grid friction top belts is {} (). The company has been in the conveyor belt industry for over 40 years, and its experience and expertise enable it to create high-quality conveyor belts that meet the varying needs of different industries.{} () offers a range of flush grid friction top belts that are tailored to the specific requirements of each industry. Their belts are versatile and suitable for various industries, including food and beverage, pharmaceutical, automotive, and electronics, among others. The company's flush grid friction top belts are made from high-quality materials that are durable and resistant to wear and tear, ensuring they have a long lifespan, reducing the need for frequent replacements.In addition to manufacturing flush grid friction top belts, {} () also provides customization services. The company can design and manufacture conveyor belts that meet the unique needs of their clients. They can tailor the belt's width, length, thickness, and surface pattern, among other specifications, depending on the client's requirements.One of the features that set {} () apart from other conveyor belt manufacturers is their commitment to quality and customer satisfaction. The company has invested in state-of-the-art equipment and employs a team of experienced professionals who ensure that each belt that leaves their facilities meets the company's high standards. They also offer excellent customer service, providing technical support and advice to clients, ensuring they make an informed decision when selecting a conveyor belt.The flush grid friction top design has numerous benefits that are revolutionizing the conveyor belt industry. Industries that have adopted this design have noticed a significant improvement in their production processes, resulting in increased efficiency, reduced downtime, and enhanced product quality.In conclusion, {} () is a leading manufacturer of flush grid friction top conveyor belts, providing high-quality products that meet the diverse needs of different industries. Their commitment to excellence and customer satisfaction makes them the ideal partner for industries seeking to optimize their production processes. With their expertise and state-of-the-art equipment, {} () is poised to continue leading the industry in innovation and exceptional service delivery.