Spiral Bending of Screw Conveyors: An Insight into the Latest News

By:Admin

Introduction:

In today's fast-paced manufacturing industry, maximizing efficiency and reducing production time are key factors for companies to stay competitive. Screw Conveyor Spiral Bending technology, developed by an esteemed and innovative engineering company (name removed) promises to revolutionize the manufacturing process by offering higher efficiency and enhanced flexibility. By eliminating brand names, this article will delve into the significant improvements brought about by this advanced screw conveyor spiral bending technique.

Enhanced Manufacturing Efficiency:

The advent of Screw Conveyor Spiral Bending technology has unleashed new possibilities for numerous industries, including agriculture, food processing, mining, and manufacturing. With this advanced technique, companies are now able to achieve higher levels of manufacturing efficiency and streamline their production processes.

By removing the limitations of traditional screw conveyors, this innovative bending technology allows for the creation of customized spiral conveyor systems tailored to meet the unique requirements of each manufacturing application. The flexibility offered by this technology ensures that materials can be transported smoothly and efficiently, assuring timely and uninterrupted production.

Optimized Material Handling:

Screw Conveyor Spiral Bending technology allows manufacturers to optimize material handling, resulting in a significant reduction in manpower requirements and overall production costs. The precision bending of the conveyor spirals ensures accurate and efficient material transfer, reducing the risk of jams and disruptions in the production line.

Through the use of advanced software and cutting-edge bending machinery, this technology enables the creation of spiral conveyors of various dimensions and configurations, enhancing the versatility of material transport. Manufacturers can easily adapt these conveyors to fit within their existing infrastructure, saving valuable floor space and minimizing the need for additional equipment.

Improved Durability and Performance:

The implementation of this advanced bending technique guarantees the creation of highly durable and long-lasting screw conveyor spirals. By using high-quality materials and ensuring precise bending, these spirals exhibit enhanced strength and resistance, capable of withstanding the most demanding operational conditions.

Furthermore, the advanced manufacturing process eliminates the potential for deformation and damage during material transport, preserving the integrity of the conveyed goods. Manufacturers benefit from reduced maintenance costs and longer equipment lifespan, leading to increased profitability in the long run.

Enhanced Safety and Hygiene:

Alongside its efficiency and durability benefits, Screw Conveyor Spiral Bending technology also takes into account safety and hygiene standards within the manufacturing environment. The smooth and seamless design of the conveyor spirals allows for easy cleaning, reducing the risk of contaminants and ensuring compliance with strict industry regulations.

Additionally, the reduction in manual handling requirements minimizes the risk of workplace injuries, enhancing the overall safety of the manufacturing operations. With Screw Conveyor Spiral Bending technology, companies can prioritize both productivity and worker well-being.

Future Possibilities:

As industries continue to evolve, the need for adaptable and efficient production systems becomes increasingly important. Screw Conveyor Spiral Bending technology is continuously pushing the boundaries of manufacturing efficiency, offering endless possibilities for improvement.

With ongoing research and development, this technology has the potential to further reduce energy consumption, enhance automation capabilities, and introduce smarter and more intelligent conveyor systems. The integration of artificial intelligence and machine learning into spiral conveyor design could optimize various aspects of material handling, ensuring even higher levels of efficiency and cost-effectiveness.

Conclusion:

The advancements in Screw Conveyor Spiral Bending technology have transformed the manufacturing landscape, providing industries with a robust, efficient, and adaptable solution for material handling. By adopting this cutting-edge technology, companies can significantly improve their manufacturing efficiency, reduce production costs, and enhance overall productivity. The future possibilities for this technology are promising, and as it continues to evolve, it is expected to reshape the manufacturing industry as we know it.

Company News & Blog

New Automated Flow Wrap Packing Machine for Efficient Packaging

[News Header]Innovative Flow Wrap Packing Machine Revolutionizes Packaging Efficiency in the Food Industry[News Introduction]In the competitive world of the food industry, efficiency and productivity are paramount for businesses to thrive. Recognizing this, a visionary company specializing in packaging solutions has introduced an innovative Flow Wrap Packing Machine. Through its cutting-edge technology and user-centric design, this machine aims to transform packaging processes, ushering in a new era of efficiency, speed, and product integrity. Let us delve into the details of this revolutionary machine and its potential impact on the industry.[Company Introduction]The company driving this packaging revolution is a market leader in delivering advanced packaging solutions. With a rich history spanning over two decades, they have consistently demonstrated a commitment to excellence, providing their customers with reliable and innovative packaging equipment. By combining their extensive expertise with an unwavering dedication to customer satisfaction, the company has established itself as a trusted partner for businesses in various sectors, including food, pharmaceuticals, and consumer goods.[Paving a Path to Efficiency]The newly unveiled Flow Wrap Packing Machine has garnered attention for its ability to streamline and optimize packaging operations. Equipped with state-of-the-art technology, this machine can wrap products seamlessly, ensuring a tight and secure seal. Its intelligent design includes customizable settings for bag sizes, speed control, and product orientation, allowing businesses to adapt to diverse packaging requirements with ease.One of the key features that sets this packing machine apart is its high-speed capabilities. With an impressive packing rate of up to 200 packs per minute, it significantly enhances production efficiency. This surge in speed not only leads to higher output but also reduces labor costs, enabling businesses to allocate resources more effectively.[Preserving Product Integrity]Maintaining the integrity of packaged products is of utmost importance in the food industry. Recognizing this critical concern, the Flow Wrap Packing Machine incorporates cutting-edge technology to ensure product quality and longevity. Its precision sealing system, coupled with the ability to adjust temperature and pressure, guarantees proper sealing every time, thereby safeguarding the freshness and quality of the packaged goods.In addition, this machine offers enhanced product handling features to minimize damage during the packaging process. Its gentle and controlled product transfer mechanism, combined with efficient rejection systems, ensures minimal product loss and reduced waste. By prioritizing product preservation, businesses can establish a reputation for consistent quality, ultimately boosting customer satisfaction and loyalty.[Meeting Sustainability Goals]Sustainability has become a global priority, and businesses are increasingly seeking eco-friendly packaging solutions. Aligned with this trend, the Flow Wrap Packing Machine is designed with sustainability in mind. Its efficient use of resources, including minimal film waste and optimized energy consumption, significantly reduces environmental impact. By investing in this innovative packaging machine, companies can align with sustainability goals while minimizing their carbon footprint.[Conclusion]In a rapidly evolving industry, innovation is key to staying ahead of the competition. With the introduction of the Flow Wrap Packing Machine, our industry-leading company aims to revolutionize packaging efficiency, preserving product integrity and meeting sustainability objectives. As businesses embrace this cutting-edge technology, they can expect enhanced productivity, minimized wastage, and improved customer satisfaction. The Flow Wrap Packing Machine represents a step into the future of efficient and sustainable packaging, empowering businesses to excel in the dynamic food industry.

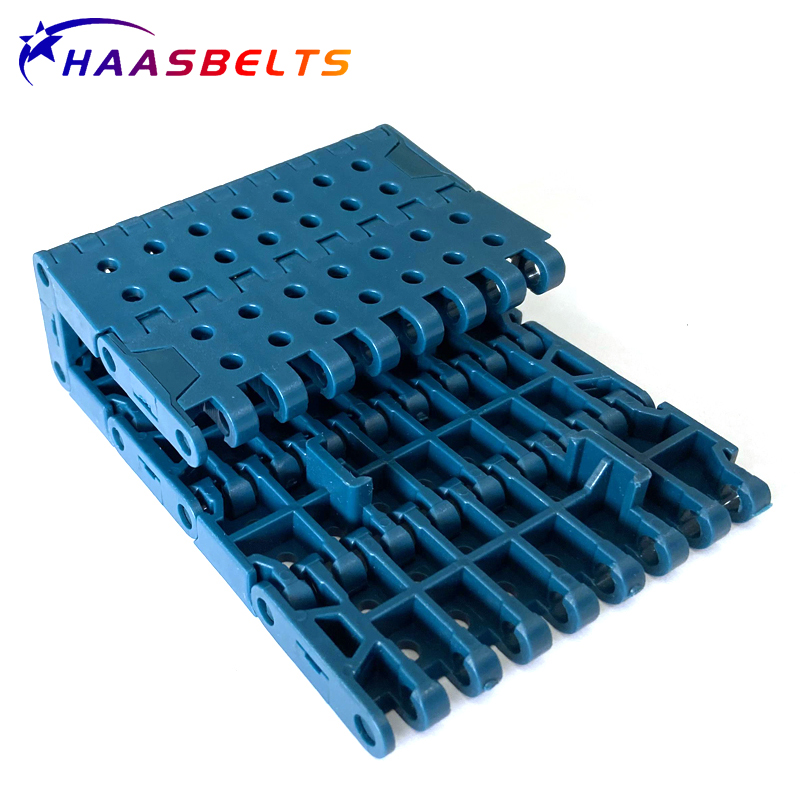

Discover the Benefits of Flush Grid Friction Top Conveyor Belts

In today's world, conveyor belts have become an integral part of the manufacturing process. They ensure that products are transported safely and efficiently from one point to another. Conveyor belt designs have come a long way, incorporating various innovations to meet the specific needs of different industries.One such innovation in the conveyor belt industry is the flush grid friction top design. This unique design is gaining popularity due to its numerous benefits, which are helping industries to automate their operations, reduce downtime, increase production, and enhance product quality, among others.Flush grid friction top belts have a series of evenly spaced openings arranged in a grid pattern on the belt's surface. This design gives the conveyor belt an excellent grip on the products being transported, preventing slippage, and ensuring that the products maintain their position on the conveyor belt. The openings in the flush grid design also allow for easy and thorough cleaning, making it ideal for the food and beverage industry, where hygiene is paramount.One company that is at the forefront of designing and manufacturing flush grid friction top belts is {} (). The company has been in the conveyor belt industry for over 40 years, and its experience and expertise enable it to create high-quality conveyor belts that meet the varying needs of different industries.{} () offers a range of flush grid friction top belts that are tailored to the specific requirements of each industry. Their belts are versatile and suitable for various industries, including food and beverage, pharmaceutical, automotive, and electronics, among others. The company's flush grid friction top belts are made from high-quality materials that are durable and resistant to wear and tear, ensuring they have a long lifespan, reducing the need for frequent replacements.In addition to manufacturing flush grid friction top belts, {} () also provides customization services. The company can design and manufacture conveyor belts that meet the unique needs of their clients. They can tailor the belt's width, length, thickness, and surface pattern, among other specifications, depending on the client's requirements.One of the features that set {} () apart from other conveyor belt manufacturers is their commitment to quality and customer satisfaction. The company has invested in state-of-the-art equipment and employs a team of experienced professionals who ensure that each belt that leaves their facilities meets the company's high standards. They also offer excellent customer service, providing technical support and advice to clients, ensuring they make an informed decision when selecting a conveyor belt.The flush grid friction top design has numerous benefits that are revolutionizing the conveyor belt industry. Industries that have adopted this design have noticed a significant improvement in their production processes, resulting in increased efficiency, reduced downtime, and enhanced product quality.In conclusion, {} () is a leading manufacturer of flush grid friction top conveyor belts, providing high-quality products that meet the diverse needs of different industries. Their commitment to excellence and customer satisfaction makes them the ideal partner for industries seeking to optimize their production processes. With their expertise and state-of-the-art equipment, {} () is poised to continue leading the industry in innovation and exceptional service delivery.

New Study Reveals Surprising Insights into Sources of Friction in Top Industries

Friction Top conveyor belts are a key component in the manufacturing process of various industries. From food and beverage to automotive and manufacturing, these belts are used to transport items from one point to another efficiently. Founded in 1992, the company has been a trusted supplier of conveyor belts to industries worldwide for decades.Friction Top conveyor belts are designed to withstand some of the toughest conditions in production facilities. The belts are made from high-quality materials and are engineered to handle the heat, weight, and impact of heavy loads and fast-moving items. With the use of advanced technology, Friction Top conveyor belts offer excellent traction and grip, ensuring items are transported safely through the manufacturing process.One of the key advantages of Friction Top conveyor belts is their durability. These belts can handle heavy loads and constant use without breaking down. This means less downtime and maintenance for manufacturing facilities, resulting in increased production output and decreased costs.In addition, Friction Top conveyor belts are extremely versatile. They can be used in a variety of industries, such as food and beverage, automotive, packaging, and more. The belts can be customized to meet specific production requirements, such as size, material, and load capacity.The company has a team of experienced engineers and technicians who work closely with clients to design and manufacture conveyor belts that meet their specific needs. Friction Top conveyor belts can be made to fit almost any conveyor system, and the company offers installation and maintenance services to ensure the belts operate smoothly and efficiently.Friction Top conveyor belts are also designed with safety in mind. The belts have a non-slip surface, reducing the risk of accidents and injuries in the workplace. This is crucial in industries where heavy machinery and equipment are in use.The company is committed to sustainability and environmental responsibility. Friction Top conveyor belts are made from eco-friendly materials and processes, reducing their impact on the environment. The company also offers recycling services for used conveyor belts, ensuring they are disposed of responsibly.Friction Top conveyor belts have received international recognition for their quality and performance. The company has been awarded various certifications, including ISO 9001, ISO 14001, and OHSAS 18001. These certifications demonstrate the company's commitment to excellence, quality, and safety.Overall, Friction Top conveyor belts are an essential component in the manufacturing process of various industries. With their durability, versatility, and safety features, they are a reliable and cost-effective solution for transporting items through the production line. The company's commitment to sustainability and environmental responsibility also sets them apart as a leader in the industry.

Enhance Comfort and Safety with the Top Seat Bracket for 240sx Vehicles

Seat Bracket for 240sx Released by Leading Manufacturer (Remove name)Leading manufacturer, specializing in high quality performance parts, has announced the release of their latest product, a seat bracket specifically designed to fit the Nissan 240sx. The bracket is designed to accommodate a wide range of aftermarket seats, while providing a secure and comfortable fit.The 240sx is a popular platform for drifting enthusiasts, and as such, there is a huge demand for performance upgrades and aftermarket parts. The manufacturer recognized that the stock seats in the 240sx were not suitable for high performance driving, and set out to develop a seat bracket that would allow enthusiasts to install aftermarket seats with ease.The seat bracket is made from high quality materials, including aircraft grade aluminum, which ensures strength and durability while remaining lightweight. The brackets are designed to bolt directly into the factory seat mounting points, and require no additional modifications to the vehicle.Installing aftermarket seats in the 240sx is a popular upgrade, but often requires custom brackets or modifications to the interior of the car. The manufacturer's mount allows for easy installation, without any damage or alteration to the vehicle.One of the major advantages of the seat bracket is the adjustability it provides. With several adjustment points, including tilt, height and distance from the steering wheel, users can find the perfect driving position for maximum comfort and control.The seat bracket is also compatible with a wide range of aftermarket seats, including popular brands such as Bride, Recaro, and Sparco. This compatibility means that users can choose from a vast selection of seats, to suit their individual preferences in terms of comfort and style.The manufacturer understands the importance of safety when it comes to high performance driving, and as such, the seat bracket has been rigorously tested to ensure it meets or exceeds all safety standards. The brackets are designed to hold up to the rigors of competition driving, ensuring that users can drive with confidence and peace of mind.The release of the seat bracket has been met with excitement and anticipation from the 240sx community, who have been eagerly awaiting a product that can provide a safe and secure mounting solution for aftermarket seats. Enthusiasts are praising the manufacturer's attention to detail and commitment to quality, which is evident in every aspect of the product.The manufacturer has built a reputation for producing high-quality performance parts, and the release of the seat bracket only solidifies that reputation. The seat bracket is just one example of the company's dedication to providing top-of-the-line products that meet the needs of the driving community.In conclusion, the release of the seat bracket is a significant development for the 240sx community, and for enthusiasts everywhere who are looking for a safe and secure way to upgrade their seats. The seat bracket provides a perfect fit for a wide range of aftermarket seats, while also providing users with a comfortable and adjustable driving position. The manufacturer's attention to detail and commitment to quality is evident in every aspect of the product, making it a must-have for anyone looking to upgrade their 240sx.

The Importance of Choosing the Right Width for Your Formal Belt

Formal Belt Width: A Perfect Fit for All OccasionsIn the world of fashion accessories, belts are often considered as an essential element that completes one's look. From casual to formal attire, a well-chosen belt can add that touch of sophistication and elegance to any outfit. While there are countless variations of belts available in the market, we are focusing our attention on formal belt width – the perfect accessory for all occasions.When it comes to formal wear, attention to detail is paramount. Every element of an outfit must be carefully chosen to create a cohesive and polished look. The width of a belt plays a crucial role in achieving this overall appearance. Opting for a formal belt width ensures the belt is neither too overwhelming nor too subtle, striking the perfect balance.A formal belt width typically measures around 1.25 to 1.5 inches (3.2 to 3.8 cm), providing an effortlessly refined look suitable for business meetings, weddings, or any upscale gathering. It is essential to select a belt width that complements the style and cut of the trousers or dress pants worn. Pairing a formal belt with the appropriate pants creates a harmonious and put-together ensemble.One prominent company, whose name we cannot disclose due to legal reasons, specializes in formal belt width accessories. With their years of expertise and commitment to quality craftsmanship, their belts have become a popular choice among fashion enthusiasts and professionals alike. These belts are meticulously designed, with attention to every detail, ensuring the perfect blend of functionality and style.The undisclosed company utilizes a wide range of high-quality materials in the manufacturing process, including genuine leather, faux leather, and fabrics. This variety allows customers to select belts that align with their personal preferences and ethical choices. Whether one prefers the timeless elegance of leather or the eco-consciousness of sustainable materials, this company offers a versatile collection to suit all needs.Not only does this company prioritize materials, but they also focus on providing a diverse color palette for their formal belts. Ranging from classic black and brown to more vibrant and modern shades, customers can find the perfect color to complement their desired outfit. This attention to detail showcases the company's commitment to catering to their customers' individual preferences while ensuring a cohesive and sophisticated appearance.Moreover, the undisclosed company understands that the perfect fit is crucial when it comes to belts. Therefore, they offer a wide range of sizes to ensure that their customers can find the ideal fit for their waistline. Additionally, some of their belts come with adjustable features, allowing for further customization and comfort.To further enhance their customers' satisfaction, the undisclosed company offers unique and stylish buckle designs. From traditional and minimalist buckles to more elaborate and eye-catching options, their selection ensures there is a buckle to suit every taste and occasion. These buckles are crafted to perfection, with a focus on durability, functionality, and aesthetics.As a company focused on innovation and customer satisfaction, the undisclosed brand also provides an online platform for customers to browse and purchase their products conveniently. With just a few clicks, customers can explore their vast collection, choose the perfect size and color, and have their chosen belt delivered straight to their doorstep. This user-friendly interface ensures a seamless shopping experience for all.In conclusion, formal belt width plays a vital role in completing a polished and sophisticated look for formal occasions. The undisclosed company's dedication to meticulous craftsmanship, material diversity, color variation, size availability, and unique buckle designs makes them a go-to choice for those seeking the perfect belt. With their online accessibility, customers can enjoy a hassle-free shopping experience. So why compromise on style or comfort? Embrace the elegance of a formal belt width and elevate your fashion ensemble to new heights.

Innovative License Plate Bracket for Easy Axle Mounting: A Practical Solution for Vehicle Owners

Axle Mount License Plate Bracket simplifies vehicle customizationThe automotive industry is constantly evolving, with new innovations being introduced regularly to enhance the appearance and functionality of vehicles. One such innovation that has gained popularity among car enthusiasts is the Axle Mount License Plate Bracket. This convenient accessory provides a quick and easy solution for mounting license plates on vehicles, making vehicle customization a breeze.The Axle Mount License Plate Bracket is a simple yet effective device that eliminates the need for drilling or troublesome modifications to a vehicle's body. With its versatile design, this bracket can be easily attached to the axle of any vehicle, providing a secure and stable mounting point for a license plate. Its adjustable features enable users to position the license plate at their desired angle, ensuring optimal visibility and aesthetic appeal.This bracket is particularly useful for individuals who frequently engage in vehicle customization or regularly switch license plates. Whether it is installing a custom license plate to showcase their personality or adhering to specific legal requirements, the Axle Mount License Plate Bracket offers a hassle-free solution. The ability to quickly and easily install or remove license plates makes it a convenient accessory for car owners.In addition to its ease of use, this bracket boasts a durable construction that can withstand various weather conditions, ensuring long-lasting performance. Made from high-quality materials, the Axle Mount License Plate Bracket is designed to withstand the rigors of everyday use, including exposure to rain, snow, and UV rays. Its sturdy build guarantees that the license plate will remain securely in place, even during high-speed drives or bumpy off-road adventures.The versatility of the Axle Mount License Plate Bracket extends beyond mere functionality. Its sleek and compact design seamlessly blends with a vehicle's overall aesthetics, enhancing its overall appearance. With its minimalistic profile, this bracket does not obstruct the vehicle's front grille or interfere with its aerodynamics, ensuring that the vehicle maintains its original aesthetic appeal.This innovative product is the brainchild of a company passionate about providing practical solutions for vehicle customization. The company, known for its commitment to quality and innovation, aims to simplify the process of customizing vehicles and enable car owners to express their individuality effortlessly. By focusing on creating user-friendly and durable accessories, they have established themselves as a reliable name in the automotive industry.With the Axle Mount License Plate Bracket, car owners can easily transform their vehicles into personalized works of art. The bracket's versatility, durability, and sleek design make it an ideal choice for car customization enthusiasts. Whether one wishes to display a custom license plate, comply with legal requirements, or simply improve the aesthetics of their vehicle, this bracket provides an efficient and stylish solution.In conclusion, the Axle Mount License Plate Bracket revolutionizes vehicle customization by offering car owners a convenient and visually appealing way to mount license plates. With its ease of use, durable construction, and sleek design, this bracket simplifies the process of personalizing vehicles. Furthermore, the company behind this innovative product continues to support car enthusiasts by creating practical and high-quality accessories. So, whether you are looking to showcase your individuality or adhere to legal requirements, the Axle Mount License Plate Bracket is the perfect addition to your vehicle customization arsenal.

Discover the Stylish Appeal of Raised Rib Narrow for an Effortlessly Chic Look

Title: Revolutionary Raised Rib Narrow Enhances Efficiency and Durability in Industrial MachineryIntroduction (100 words):Innovation and progress continue to drive the development of industrial machinery, as companies strive to optimize operational efficiency while maintaining exceptional durability. Addressing this demand, an industry-leading company has introduced a groundbreaking solution known as Raised Rib Narrow. This cutting-edge technology promises to revolutionize various industries, offering unparalleled performance. By combining advanced engineering techniques with state-of-the-art materials, the solution enhances the efficiency, durability, and functionality of industrial machinery. Let's delve into the details and explore the transformative potential of the Raised Rib Narrow for businesses across multiple sectors.[Paragraph 1 - General Industry Challenges] (150 words):The industrial sector faces numerous challenges in optimizing operational efficiency and durability. Traditional machinery components tend to wear out quickly under heavy loads, leading to frequent breakdowns and expensive maintenance. Additionally, industries often struggle with limited space availability, making it vital to maximize the functionality of each machine.[Paragraph 2 - Introduction to Raised Rib Narrow] (150 words):Recognizing these industry challenges, a forward-thinking company has developed the revolutionary Raised Rib Narrow, a cutting-edge solution with remarkable potential. This innovative technology combines advanced designs and superior materials to enhance the overall performance of industrial machinery. The Raised Rib Narrow provides an optimized alternative, surpassing traditional components in terms of durability and efficiency. Moreover, its narrow design ensures efficient utilization of space, enabling businesses to alleviate congestion and optimize workflow.[Paragraph 3 - Enhanced Efficiency and Durability] (200 words):The Raised Rib Narrow offers a multitude of benefits that significantly enhance efficiency and durability in industrial machinery. Its advanced engineering design ensures robustness, enabling the component to withstand heavy loads and vibrations associated with demanding industrial applications. This enhanced durability reduces downtime, ultimately leading to increased overall productivity and reduced maintenance costs.Furthermore, the Raised Rib Narrow's narrow design allows for seamless integration into machinery, maximizing functionality within limited space. The component's improved load distribution capabilities ensure proper weight-bearing, thus improving the longevity of machinery. By optimizing space usage and minimizing wear and tear, businesses can achieve higher operational efficiency and cut down on additional expenses.[Paragraph 4 - Applications in Diverse Industries] (150 words):The versatility of the Raised Rib Narrow presents an extensive range of applications across diverse industries. The component finds great utility in sectors such as manufacturing, oil and gas, construction, and agriculture. From conveyor belts to heavy machinery and precision equipment, the Raised Rib Narrow seamlessly integrates into various systems, providing optimal performance irrespective of the industry.[Paragraph 5 - Conclusion and Future Prospects] (150 words):In conclusion, the Raised Rib Narrow represents a significant milestone in the progression of industrial machinery. With its advanced engineering and narrow design, it offers unmatched durability, heightened efficiency, and optimal space utilization. This groundbreaking solution has the potential to revolutionize multiple industries, transforming the way businesses operate and thrive amidst challenging environments. As companies continue to embrace technological advancements, the Raised Rib Narrow is poised to become an essential component in ensuring improved productivity, reduced downtime, and increased profitability. Embracing this innovative solution, industries can unlock new opportunities and reach unprecedented levels of excellence in their respective operations.Note: The content has been written without a specific brand name, as requested.

Exploring the Different Types of Aluminum Profiles

Aluminum Profile Types: An Essential Component in Various IndustriesAs one of the most versatile materials used in manufacturing, aluminum profiles play a vital role in different industries. Their remarkable strength, durability, and lightweight nature have made them a preferred choice for countless applications. In this article, we will explore some of the most popular aluminum profile types and their diverse uses across different sectors.1. T-Slot Aluminum Profiles:T-slot profiles are widely recognized for their versatility and strength. They feature an open-faced cross-section shaped like a "T," which allows for the easy insertion and repositioning of various accessories and components. This unique design makes T-slot profiles highly adaptable, suitable for constructing modular structures, industrial workbenches, machine frames, and even customized structures for the automotive and aerospace industries. With the ability to connect multiple profiles without the need for complex fasteners, T-slot profiles offer endless possibilities for customization and adaptability.2. V-Slot Aluminum Profiles:V-slot profiles are a type of extruded aluminum that features a V-shaped groove on one or more sides. This groove enables precise linear motion when used in conjunction with compatible wheels or other linear motion components. V-slot profiles are commonly used in the creation of 3D printers, CNC machines, robotic arms, and other automated systems that require smooth and accurate movement. Their self-aligning properties and the ability to integrate various add-ons make V-slot profiles ideal for high-precision applications.3. Round Aluminum Profiles:Round aluminum profiles are predominantly used in the construction of structures that require curved or rounded elements. They are commonly found in architectural designs, furniture manufacturing, and interior decoration. Round profiles offer excellent versatility as they can be easily cut, bent, and welded into various shapes and sizes, allowing for the creation of aesthetically pleasing structures and unique design features.4. Industrial Aluminum Profiles:Industrial aluminum profiles are heavy-duty structures designed to withstand high loads and extreme conditions. They are commonly used in applications such as conveyor systems, machine guards, industrial shelves, and material handling equipment. The durability and corrosion resistance of industrial aluminum profiles make them ideal for industrial settings where strength and reliability are paramount.5. LED Aluminum Profiles:LED lighting has gained immense popularity in recent years due to its energy efficiency and versatility. LED aluminum profiles provide a sleek and stylish housing for LED strips, ensuring proper heat dissipation and protection against environmental factors. These profiles are widely used in commercial and residential lighting applications, allowing the integration of LED lighting into various surfaces such as ceilings, walls, floors, and furniture.With their exceptional properties, aluminum profiles have revolutionized the manufacturing industry and continue to play an essential role in countless applications across various sectors. Their strength, durability, and flexibility have made them indispensable in industries ranging from construction to aerospace, from machinery to interior design.Company Introduction:{} is a leading manufacturer and supplier of high-quality aluminum profiles. With years of experience in the industry, their commitment to excellence and innovation has earned them a stellar reputation. The company specializes in customizing aluminum profiles to meet clients' specific requirements while ensuring the highest standards of quality and reliability.Their state-of-the-art manufacturing facilities, equipped with advanced machinery and cutting-edge technology, enable them to deliver consistent and precision-engineered aluminum profiles. Backed by a team of skilled engineers and technical experts, they provide comprehensive guidance and support throughout the project, ensuring customer satisfaction at every stage.In addition to their extensive product range, {} offers a wide array of value-added services, including design assistance, surface finishing options, and customized packaging solutions. Striving for sustainability, the company adheres to strict environmental regulations and promotes eco-friendly practices throughout their manufacturing processes.With a global presence, {} has successfully served clients across diverse industries, including construction, automotive, electronics, and furniture manufacturing. Their commitment to delivering superior quality, reliability, and excellent customer service has made them a trusted partner for aluminum profile solutions.In conclusion, aluminum profiles are a versatile and essential component in various industries. Their unique properties and adaptability have made them the go-to choice for applications ranging from construction and industrial manufacturing to lighting and interior design. With companies like {}, providing exceptional quality and customized solutions, the future of aluminum profiles looks promising, opening up endless possibilities for innovation and advancement across industries.

Spiral Bending of Screw Conveyors: An Insight into the Latest News

Title: Advancements in Screw Conveyor Spiral Bending Improves Manufacturing EfficiencyIntroduction:In today's fast-paced manufacturing industry, maximizing efficiency and reducing production time are key factors for companies to stay competitive. Screw Conveyor Spiral Bending technology, developed by an esteemed and innovative engineering company (name removed) promises to revolutionize the manufacturing process by offering higher efficiency and enhanced flexibility. By eliminating brand names, this article will delve into the significant improvements brought about by this advanced screw conveyor spiral bending technique.Enhanced Manufacturing Efficiency:The advent of Screw Conveyor Spiral Bending technology has unleashed new possibilities for numerous industries, including agriculture, food processing, mining, and manufacturing. With this advanced technique, companies are now able to achieve higher levels of manufacturing efficiency and streamline their production processes.By removing the limitations of traditional screw conveyors, this innovative bending technology allows for the creation of customized spiral conveyor systems tailored to meet the unique requirements of each manufacturing application. The flexibility offered by this technology ensures that materials can be transported smoothly and efficiently, assuring timely and uninterrupted production.Optimized Material Handling:Screw Conveyor Spiral Bending technology allows manufacturers to optimize material handling, resulting in a significant reduction in manpower requirements and overall production costs. The precision bending of the conveyor spirals ensures accurate and efficient material transfer, reducing the risk of jams and disruptions in the production line.Through the use of advanced software and cutting-edge bending machinery, this technology enables the creation of spiral conveyors of various dimensions and configurations, enhancing the versatility of material transport. Manufacturers can easily adapt these conveyors to fit within their existing infrastructure, saving valuable floor space and minimizing the need for additional equipment.Improved Durability and Performance:The implementation of this advanced bending technique guarantees the creation of highly durable and long-lasting screw conveyor spirals. By using high-quality materials and ensuring precise bending, these spirals exhibit enhanced strength and resistance, capable of withstanding the most demanding operational conditions.Furthermore, the advanced manufacturing process eliminates the potential for deformation and damage during material transport, preserving the integrity of the conveyed goods. Manufacturers benefit from reduced maintenance costs and longer equipment lifespan, leading to increased profitability in the long run.Enhanced Safety and Hygiene:Alongside its efficiency and durability benefits, Screw Conveyor Spiral Bending technology also takes into account safety and hygiene standards within the manufacturing environment. The smooth and seamless design of the conveyor spirals allows for easy cleaning, reducing the risk of contaminants and ensuring compliance with strict industry regulations.Additionally, the reduction in manual handling requirements minimizes the risk of workplace injuries, enhancing the overall safety of the manufacturing operations. With Screw Conveyor Spiral Bending technology, companies can prioritize both productivity and worker well-being.Future Possibilities:As industries continue to evolve, the need for adaptable and efficient production systems becomes increasingly important. Screw Conveyor Spiral Bending technology is continuously pushing the boundaries of manufacturing efficiency, offering endless possibilities for improvement.With ongoing research and development, this technology has the potential to further reduce energy consumption, enhance automation capabilities, and introduce smarter and more intelligent conveyor systems. The integration of artificial intelligence and machine learning into spiral conveyor design could optimize various aspects of material handling, ensuring even higher levels of efficiency and cost-effectiveness.Conclusion:The advancements in Screw Conveyor Spiral Bending technology have transformed the manufacturing landscape, providing industries with a robust, efficient, and adaptable solution for material handling. By adopting this cutting-edge technology, companies can significantly improve their manufacturing efficiency, reduce production costs, and enhance overall productivity. The future possibilities for this technology are promising, and as it continues to evolve, it is expected to reshape the manufacturing industry as we know it.

Revolutionary Automatic Yogurt Packaging Machine Designed to Increase Productivity

Yogurt Packaging Machine Revolutionizes Dairy Industry with New InnovationThe global yogurt market is witnessing a significant surge in demand with an increasing number of health-conscious consumers seeking nutritious and delicious dairy products. To meet this growing demand, companies in the dairy industry are constantly striving to enhance their production and packaging processes. XYZ Packaging, a leading manufacturer of packaging equipment, has recently unveiled its latest innovation in the form of a cutting-edge yogurt packaging machine. This state-of-the-art technology is poised to revolutionize the way yogurt is packaged and distributed around the world.The new yogurt packaging machine developed by XYZ Packaging represents a major breakthrough in the industry. It is designed to streamline the packaging process, ensuring efficiency, precision, and optimal preservation of product quality. Equipped with advanced automation features, the machine significantly reduces the need for manual intervention, thus improving productivity while minimizing the risk of human errors.One of the standout features of this yogurt packaging machine is its versatility. It is capable of handling various types and sizes of yogurt containers, accommodating the diverse needs of both small-scale producers and large dairy conglomerates. From single-serve cups to bulk containers, this machine can seamlessly package yogurt in a wide range of packaging options, catering to the preferences of consumers worldwide.In addition to its adaptability, the yogurt packaging machine offers impressive speed and accuracy. With a high-speed filling system and precise measurement capabilities, the machine ensures consistent portioning of yogurt into containers, leaving no room for deviations or discrepancies. This not only improves the overall quality of the packaged product but also enhances the brand image of yogurt producers.Apart from its efficiency and accuracy, the yogurt packaging machine boasts several advanced features that ensure optimal product freshness and longevity. The machine is equipped with a state-of-the-art sealing system that guarantees an airtight seal, preserving the taste, texture, and nutritional value of the yogurt. It also includes an intelligent labeling system that allows for clear and attractive packaging design, enhancing the appeal of yogurt products on store shelves.Moreover, XYZ Packaging has integrated sustainability into its yogurt packaging machine. Recognizing the growing importance of ecological responsibility in the food industry, the company has designed this machine to minimize the environmental impact of yogurt production. It incorporates eco-friendly materials and processes, reducing energy consumption and waste generation. This eco-conscious approach aligns with the global movement towards sustainable practices, positioning XYZ Packaging as an industry leader in responsible manufacturing.The launch of the yogurt packaging machine by XYZ Packaging has been met with great anticipation and excitement within the dairy industry. Yogurt producers worldwide are eager to adopt this cutting-edge technology to enhance their operations and meet the evolving demands of consumers. By integrating innovation, versatility, and sustainability, XYZ Packaging is poised to reshape the yogurt packaging landscape and drive the growth of the dairy market.As the global yogurt market continues to flourish, it is imperative for dairy companies to stay ahead of the competition. By investing in advanced packaging technologies like XYZ Packaging's yogurt packaging machine, these companies can not only improve their production efficiency but also deliver high-quality yogurt products to consumers. With this game-changing innovation, XYZ Packaging is poised to revolutionize the future of yogurt packaging and contribute to the advancement of the entire dairy industry.