Choosing the Standard Belt Width in Millimeters: What You Need to Know

By:Admin

With a wide range of belt widths available in the market, it is essential to understand the standard belt width in mm for optimal performance. The standard belt width in mm is typically determined by the specific application and industry requirements. Understanding the standard belt width in mm can help manufacturers and businesses make informed decisions when it comes to selecting the right belt for their operations.

The standard belt width in mm varies across different industries and applications. For example, in the food and beverage industry, the standard belt width in mm may be different compared to the automotive or packaging industry. It is important for manufacturers to be aware of the industry standards and requirements when selecting a belt width for their specific application.

In addition to industry standards, it is also important to consider the specific requirements of the application when determining the standard belt width in mm. Factors such as the size and weight of the products being conveyed, the speed of the production line, and the layout of the conveyor system all play a role in determining the optimal belt width.

Furthermore, a company introduction is a crucial part of any news piece. {} is a leading provider of conveyor belts and accessories, with a strong focus on quality, innovation, and customer satisfaction. With a wide range of products and solutions designed to meet the needs of various industries, {} has established itself as a reliable partner for businesses seeking efficient and reliable conveyor belt systems.

One of the key strengths of {} is its commitment to staying abreast of industry standards and requirements. By understanding the standard belt width in mm and other key specifications, {} is able to provide its customers with the most suitable and effective conveyor belt solutions for their operations.

The company's dedication to quality and performance is reflected in its product offerings, which are designed to meet the highest standards of reliability and efficiency. From food-grade belts for the food and beverage industry to heavy-duty belts for industrial applications, {} offers a diverse range of products to cater to a wide range of customer needs.

Furthermore, {} is committed to providing comprehensive support and service to its customers, helping them optimize their conveyor belt systems for maximum efficiency and productivity. By offering expert advice and guidance, {} ensures that its customers are able to make informed decisions when it comes to selecting the right belt width and other specifications for their operations.

In conclusion, the standard belt width in mm is a critical factor in the selection of conveyor belt systems for various industries. With the support of industry-leading companies like {}, businesses can benefit from expert guidance and high-quality products to meet the standard belt width in mm and other key requirements for their specific applications. By staying informed about industry standards and specifications, businesses can ensure that their conveyor belt systems are optimized for maximum performance and efficiency.

Company News & Blog

High-Quality 1 Inch Square Tubing End Caps: A Must-Have for Various Projects

In today's world, one of the most important aspects of manufacturing and construction is ensuring that the products being produced are of the highest quality and durability. This is particularly important when it comes to steel tubing, as it is often used in a variety of industries and applications where consistency and strength are paramount. Fortunately, there are products available on the market today that are specifically designed to provide additional protection and support to steel tubing, including the highly effective 1 inch square tubing end caps.These end caps are designed to fit snugly over the ends of 1 inch steel tubing, effectively sealing the ends and providing additional protection against weathering, impact, and other types of damage. Made from high-quality materials and crafted to precise tolerances, these end caps are an essential component of any steel tubing construction project, ensuring that the finished product remains strong and reliable over time.The 1 inch square tubing end caps are particularly popular among those in the fencing and construction industries, as they offer a simple yet effective way to help protect and secure steel tubing in a variety of applications. Whether you are building a fence, railing, or other type of structure that incorporates steel tubing, these end caps are a must-have item that can help ensure the longevity and durability of your project.One of the key advantages of these end caps is their versatility. They can be used in a variety of different applications, from industrial and commercial projects to residential DIY projects. Additionally, they are available in a variety of different sizes and materials, making it easy to find the perfect solution for your specific needs.What makes these end caps stand out from other similar products on the market is their superior quality and durability. Made from high-quality materials that are designed to resist corrosion, weathering, and other types of damage, these end caps are built to last. Additionally, they are designed to fit snugly over the ends of 1 inch steel tubing, ensuring a secure and reliable fit that will provide outstanding protection and support over time.Another advantage of these end caps is their ease of installation. Unlike other types of protective and support products that can be complicated or difficult to install, these end caps are simple and straightforward to use. They can be easily slipped onto the ends of 1 inch steel tubing, requiring only a few basic tools and a minimal amount of time and effort.In addition to their superior quality and ease of use, these end caps are also an affordable option for those looking to protect and secure their steel tubing. They are available in a variety of different price points, making it easy to find a solution that fits within your budget.Overall, 1 inch square tubing end caps are an essential component of any steel tubing construction project. They are versatile, durable, and easy to use, helping to ensure the longevity and reliability of your steel tubing structures. Whether you are working on a commercial project or a DIY project at home, be sure to consider incorporating these end caps into your design for maximum protection and support.

High-Quality Food Tray Sealing Machine for Efficient Packaging

Food Tray Sealing Machine Revolutionizing the Food Packaging IndustryIn recent years, the food packaging industry has seen significant advancements in technology and machinery, one of which is the Food Tray Sealing Machine. This innovative piece of equipment has been revolutionizing the way food is packaged and sealed, providing numerous benefits for both producers and consumers.A Food Tray Sealing Machine is an essential piece of equipment for any food packaging company, as it ensures that food products are securely sealed and protected from external contaminants. This machine is capable of sealing a wide range of food trays, including those made from plastic, aluminum, and even biodegradable materials, making it a versatile and essential tool for any packaging operation.One company that has been leading the way in the development and distribution of Food Tray Sealing Machines is {}.{} is a renowned manufacturer and supplier of food packaging machinery, with a strong focus on innovation and quality. Their range of Food Tray Sealing Machines has gained widespread popularity in the food packaging industry, thanks to their cutting-edge technology and user-friendly design.Their Food Tray Sealing Machines are designed to provide efficient and reliable sealing for a variety of food products, including ready-to-eat meals, fresh produce, and snacks. The machines are capable of sealing different types of trays, including those with compartments or irregular shapes, ensuring that all food products are securely sealed for freshness and safety.The company’s Food Tray Sealing Machines are equipped with advanced sealing technology, including heat sealing and vacuum sealing, to provide the best possible protection for food products. Additionally, these machines are designed for easy operation and maintenance, allowing food packaging companies to increase their productivity and efficiency while ensuring the highest standards of food safety and quality.In addition to their innovative technology, {} also offers customizable options for their Food Tray Sealing Machines, allowing food packaging companies to adapt the machines to their specific needs and production requirements. This flexibility has made {} a trusted partner for many food packaging companies, enabling them to improve their packaging processes and meet the demands of an ever-changing market.One of the key advantages of using a Food Tray Sealing Machine from {} is its ability to extend the shelf life of food products. By securely sealing the food trays, the machines help to prevent contamination and spoilage, ensuring that the products remain fresh and safe for consumption for a longer period of time. This not only benefits food packaging companies by reducing product waste but also provides consumers with high-quality, fresh food products.Furthermore, the use of a Food Tray Sealing Machine also contributes to sustainable packaging practices. With the increasing demand for eco-friendly packaging solutions, {} has developed Food Tray Sealing Machines that are compatible with biodegradable and compostable food trays, allowing food packaging companies to align with environmentally conscious practices and meet consumer preferences.As the food packaging industry continues to evolve, the demand for efficient, reliable, and sustainable packaging solutions remains strong. With the advancements in Food Tray Sealing Machine technology, companies like {} are paving the way for the future of food packaging, providing innovative solutions that benefit both producers and consumers.In conclusion, the Food Tray Sealing Machine has become an indispensable tool for food packaging companies, offering advanced sealing technology, customization options, and sustainable packaging solutions. The innovative machines developed by {} are revolutionizing the food packaging industry, helping companies improve their production processes, extend the shelf life of their products, and meet the demands of an increasingly eco-conscious market. With their commitment to innovation and quality, {} is setting the standard for excellence in food packaging machinery, and their Food Tray Sealing Machines are poised to continue making a significant impact on the industry for years to come.

Discover the Latest Trends in Steel Cladding Profiles for Enhanced Aesthetics and Durability

[Your Name][Your Title][Date][News Outlet Name / Website]Headline: Steel Cladding Profiles: A New Era of Innovation and Sustainability in ConstructionIntroduction:In an era where construction projects are evolving rapidly, the demand for high-quality building materials is at an all-time high. One company leading the charge in this sector is Steel Cladding Profiles (SCP), a globally renowned manufacturer of cutting-edge steel cladding products. SCP's commitment to innovation, sustainability, and customer satisfaction have made them a go-to choice for architects, builders, and developers worldwide.Body:1. Introduction to Steel Cladding Profiles:Steel Cladding Profiles (SCP) has been an industry leader in the manufacturing of steel cladding products for over two decades. Headquartered in [Headquarters Location], SCP has steadily expanded its operations globally, catering to a diverse array of construction projects, including commercial buildings, residential complexes, and industrial facilities. The company's core principles revolve around quality, sustainability, and customer-centricity.2. Innovation in Steel Cladding:SCP's dedication to innovation has positioned them as pioneers in the field of steel cladding. Their state-of-the-art research and development facility is constantly exploring new techniques and materials to enhance the strength, durability, and aesthetic appeal of their products. SCP's team of skilled engineers and designers collaborate closely with clients to customize cladding solutions that meet their specific requirements, often surpassing industry standards.3. Sustainability at the Heart of SCP's Operations:In an era where environmental consciousness is paramount, SCP's commitment to sustainability sets them apart. The company employs advanced manufacturing processes that minimize energy consumption and waste generation. Moreover, SCP's steel cladding profiles are often made from recycled materials, reducing the need for virgin resources. By offering sustainable solutions without compromising quality or performance, SCP helps construction projects contribute to a greener, more sustainable future.4. Product Portfolio:SCP offers a diverse range of steel cladding profiles that cater to various architectural styles and project needs. Their product portfolio includes the following:- Ribbed Profiles: SCP's ribbed profiles provide superior architectural aesthetics while enhancing structural stability. These profiles are ideal for commercial and residential buildings seeking a modern and sleek appearance.- Corrugated Profiles: SCP's corrugated profiles offer both strength and flexibility, making them suitable for large-span constructions. These profiles ensure water-tightness and are often used in industrial complexes and warehouses.- Standing Seam Profiles: SCP's standing seam profiles are renowned for their weather resistance and longevity. With concealed fasteners and a distinctive raised seam, these profiles are perfect for roofing applications in both residential and commercial projects.- Insulated Panels: SCP's insulated panels combine superior insulation properties with appealing aesthetics. These panels are an ideal choice for energy-efficient constructions, promoting reduced heating and cooling costs.5. Global Reach and Success Stories:SCP's dedication to quality and customer satisfaction has enabled them to establish a global footprint. From large-scale infrastructure projects to architectural marvels, SCP's steel cladding profiles have been used in projects across the world. Notable success stories include the iconic [Name of Project], which showcases the company's commitment to excellence and innovation.Conclusion:Steel Cladding Profiles (SCP) has emerged as a leading manufacturer of steel cladding products, setting new industry standards in innovation, sustainability, and customer satisfaction. SCP's diverse product portfolio, commitment to quality, and global reach make them the preferred choice for architects, builders, and developers looking for high-performance cladding solutions. With SCP, construction projects can embrace a new era of innovation and sustainability, ushering in a brighter future for the industry as a whole.[Word Count: 654]

How to Weld Square Tubing End to End: A Step-by-Step Guide

Title: Welding Square Tubing End To End: A Prominent Solution for Seamless ConnectionsIntroduction:Welding square tubing end to end has emerged as a popular technique across various industries, enabling seamless and robust connections between tubes. This highly versatile method has revolutionized the manufacturing and construction sectors, allowing for greater structural integrity, superior performance, and enhanced aesthetics. Several companies have become leaders in this field, striving to provide innovative solutions for joining square tubing in a reliable, efficient, and cost-effective manner.Company Introduction:With a strong focus on delivering cutting-edge welding solutions, [Company Name] has made significant strides in the industry. Recognized for its commitment to excellence, the company has established a reputation for providing high-quality products, outstanding customer service, and unparalleled expertise. Employing a team of experienced professionals and leveraging advanced technologies, [Company Name] has become a trusted partner for various businesses seeking welding solutions for their square tubing requirements.News Content:1. Importance of Welding Square Tubing End To End:Joining square tubing end to end through welding plays a crucial role in several industries, including construction, manufacturing, and infrastructure development. This technique ensures the creation of continuous, sturdy connections that are capable of withstanding heavy loads, vibrations, and environmental factors. Welded square tubing effectively eliminates the need for bulky connectors or additional support, resulting in improved aesthetics and versatile design possibilities.2. Advantages of Welding Square Tubing End To End:By selecting the appropriate welding method and using state-of-the-art equipment, companies like [Company Name] can offer numerous benefits associated with welding square tubing end to end. These advantages include:a) Seamless Integration: Welding ensures a seamless integration of square tubes, where the joint area is just as strong as the rest of the material, eliminating weak points.b) Enhanced Structural Integrity: The welded joint provides superior strength and durability, making it suitable for applications that require high structural integrity and load-bearing capabilities.c) Efficient and Cost-Effective: Welding square tubing end to end is a rapid and efficient process that reduces the time and cost associated with assembly. It eliminates the need for additional connectors or fasteners, streamlining production and minimizing expenses.d) Aesthetic Appeal: Due to its ability to create flush connections, welded square tubing end to end results in clean, visually appealing finishes, making it an ideal choice for architectural and decorative applications.3. [Company Name] Revolutionizes the Square Tubing Welding Industry:[Company Name] has taken a pioneering role in the development and improvement of welding techniques for square tubing. Its continuous research and development efforts have led to the introduction of advanced welding processes, ensuring optimal performance in various applications.a) Cutting-edge Technologies: By utilizing state-of-the-art welding equipment, [Company Name] maintains the highest standards of quality and precision in the welding process. Advanced technologies allow for increased efficiency, reduced defects, and exceptional craftsmanship.b) Tailored Solutions: [Company Name] understands that each customer's needs are unique, and therefore, offers customized welding solutions that meet specific project requirements. This includes welding square tubing of different sizes, thicknesses, and materials to cater to diverse industry demands.c) Collaborative Approach: [Company Name] values collaboration and works closely with clients to gain a comprehensive understanding of their welding needs. This approach enables the company to provide tailor-made solutions that fulfill the desired outcome, ensuring customer satisfaction.Conclusion:The technique of welding square tubing end to end has proven to be a game-changer in the manufacturing and construction sectors. Through this method, superior structural integrity, enhanced aesthetics, and efficient assembly processes are achieved. [Company Name], with its commitment to excellence, cutting-edge technologies, and customized solutions, emerges as a leading provider of welding services, revolutionizing the square tubing welding industry.

Discover the Versatility and Durability of Stainless Steel Profile Wall Paneling

Stainless Steel Profile Wall Paneling Reinvents Modern Interior DesignInnovative interior design solutions are constantly pushing the boundaries of creativity and functionality. Among the latest trends in modern architecture, Stainless Steel Profile Wall Paneling stands as a significant breakthrough, revolutionizing the way we envision interior spaces. With its sleek and contemporary aesthetic, this cutting-edge material has rapidly gained popularity in various residential and commercial projects.Engineered for both durability and style, Stainless Steel Profile Wall Paneling is a versatile design choice that offers numerous advantages over traditional wall coverings. Its unique composition combines the industrial appeal of stainless steel with the clean lines and customizable dimensions of paneling, resulting in a visually striking and functional solution for any interior.One of the many advantages of Stainless Steel Profile Wall Paneling lies in its durability. Stainless steel is known for its corrosion resistance, making it particularly useful in areas with high moisture levels, such as kitchens and bathrooms. Additionally, its resistance to stains, impacts, and scratches ensures a long-lasting and low-maintenance surface. This aspect makes Stainless Steel Profile Wall Paneling ideal for high-traffic areas or spaces prone to wear and tear.Moreover, Stainless Steel Profile Wall Paneling’s unique aesthetic provides a contemporary and sophisticated ambiance to any room. Its sleek and reflective surface adds depth and dimension while effortlessly complementing different design styles. From minimalist to industrial, Stainless Steel Profile Wall Paneling effortlessly enhances the visual appeal of any interior. The ability to choose from various finishes further amplifies its versatility, allowing designers and homeowners to align the material with their desired atmosphere.Installation convenience is another standout feature of Stainless Steel Profile Wall Paneling. The panels are engineered for seamless interlocking, ensuring a hassle-free and time-efficient installation process. This minimizes disruption during construction or renovation projects, making it a preferred choice for both professionals and homeowners seeking efficient design solutions.Given its versatility, Stainless Steel Profile Wall Paneling is suited for both residential and commercial applications. In homes, it can be utilized to create an accent wall, an eye-catching backsplash, or as a unique surface for kitchen cabinets. In commercial spaces, Stainless Steel Profile Wall Paneling serves as an innovative and lasting design choice for hotel lobbies, restaurants, retail stores, and office spaces.As a leader in the field, {} has positioned itself at the forefront of Stainless Steel Profile Wall Paneling innovation. With years of expertise and an expansive range of options, they offer unparalleled quality and service to clients worldwide. Their commitment to excellence is reflected in their meticulous design process and focus on sustainability. By utilizing state-of-the-art technology, they ensure the highest precision and craftsmanship in each panel, resulting in a flawlessly finished product.In conclusion, Stainless Steel Profile Wall Paneling is revolutionizing modern interior design, providing remarkable durability, versatility, and aesthetic appeal. Its sleek and contemporary nature, combined with a range of finishes, allows it to seamlessly integrate into various design styles and applications. As the demand for innovative design solutions continues to grow, Stainless Steel Profile Wall Paneling stands as a testament to the industry's commitment to pushing boundaries and reinventing interior spaces. With {}'s expertise in the field, this pioneering material is set to become an essential element in modern architecture.

Highly Efficient Industrial Vacuum Sealing Machine for Packaging Applications

Industrial Vacuum Sealing Machine: Revolutionizing Food PackagingIn recent years, the food packaging industry has seen significant advancements in technology, particularly in the area of vacuum sealing. This has led to improved food preservation, extended shelf life, and enhanced product quality. One of the leading companies at the forefront of this innovation is {company name}.{Company name} has introduced a state-of-the-art industrial vacuum sealing machine that has been generating a buzz in the industry. This machine is designed to meet the high demands of food manufacturers and processors, providing a cost-effective and efficient solution for their packaging needs.The industrial vacuum sealing machine is equipped with advanced features that set it apart from traditional packaging equipment. Its high-speed sealing capability allows for increased productivity, making it suitable for large-scale production. The machine also boasts precise control over the vacuum and sealing process, ensuring that each package is tightly sealed to maintain product freshness.{Company name} has a solid reputation for delivering high-quality and reliable packaging machinery to its customers. With a strong focus on research and development, the company has been able to stay ahead of the curve and provide innovative solutions that meet the evolving needs of the food industry.In addition to its cutting-edge technology, {company name} takes pride in its commitment to customer satisfaction. The company offers comprehensive support and training to ensure that its clients can maximize the benefits of the industrial vacuum sealing machine. This dedication to customer service has earned {company name} a loyal and satisfied customer base.The industrial vacuum sealing machine from {company name} is also designed with sustainability in mind. It is energy-efficient and minimizes packaging waste, aligning with the growing demand for eco-friendly practices in the food industry. By investing in this advanced technology, food manufacturers and processors can reduce their environmental footprint while improving their packaging processes.Furthermore, the machine is versatile and can accommodate a wide range of packaging materials, including flexible pouches, foil bags, and vacuum-sealed containers. This flexibility allows food companies to package a variety of products with ease, making it a valuable asset for their operations.In a competitive market where food safety and quality are paramount, the industrial vacuum sealing machine from {company name} offers a reliable solution that meets industry standards. Its advanced features and precision engineering have made it a game-changer for food packaging, setting a new standard for efficiency and excellence.As the demand for vacuum-sealed products continues to grow, {company name} remains committed to advancing its technology and providing innovative solutions to its customers. With a focus on continuous improvement, the company is poised to lead the way in shaping the future of food packaging.In conclusion, {company name} has introduced an industrial vacuum sealing machine that is revolutionizing the way food products are packaged. With its advanced technology, commitment to customer satisfaction, and focus on sustainability, the company is driving positive change in the food industry. As the demand for efficient and high-quality packaging solutions continues to rise, {company name} is well-positioned to meet the needs of its customers and continue its legacy of innovation.

Best Belt Widths for Everyday Wear

Normal Belt Width (NBW) is a leading manufacturer of high-quality belts for a variety of uses. With a commitment to innovation and a focus on customer satisfaction, NBW has become a trusted name in the industry.Established in 1995, NBW has a long history of providing top-notch belts to customers around the world. The company's dedication to quality and craftsmanship has earned it a reputation for excellence, and it continues to be a leader in the belt manufacturing industry.One of the key aspects of NBW's success is its range of belt widths. The company offers a wide variety of widths to meet the needs of customers in different industries. From narrow belts for delicate machinery to wide belts for heavy-duty applications, NBW has the perfect solution for every need.NBW's commitment to providing a wide range of belt widths is part of its overall dedication to meeting the diverse needs of its customers. The company understands that different industries and applications require different belt widths, and it has worked hard to develop a comprehensive range of options to ensure that all customers can find the perfect belt for their specific requirements.In addition to its wide range of belt widths, NBW is also known for its commitment to using high-quality materials in its manufacturing process. The company sources the finest materials from around the world to ensure that its belts are durable, reliable, and long-lasting. By using top-quality materials, NBW is able to deliver belts that meet the highest standards of performance and reliability.NBW's dedication to quality and innovation extends to its manufacturing processes as well. The company utilizes the latest technology and equipment to produce its belts, ensuring that every product meets the highest standards of precision and quality. This commitment to innovation and efficiency allows NBW to maintain a high level of productivity while also upholding its reputation for excellence.Customers in a wide range of industries rely on NBW for their belt needs. From industrial machinery to automotive applications, NBW's belts are trusted by customers around the world to deliver exceptional performance and reliability. Whether it's a narrow belt for a delicate piece of equipment or a wide belt for a heavy-duty application, NBW has the perfect solution for every customer.The company's dedication to providing a wide range of belt widths is just one example of its commitment to meeting the diverse needs of its customers. By offering a comprehensive range of options, NBW ensures that every customer can find the perfect belt for their specific requirements, no matter what industry they are in.In conclusion, Normal Belt Width (NBW) is a leading manufacturer of high-quality belts, known for its commitment to innovation, quality, and customer satisfaction. With a wide range of belt widths to meet the needs of customers in different industries, NBW continues to be a trusted name in the belt manufacturing industry. Whether it's a narrow belt for delicate machinery or a wide belt for heavy-duty applications, customers around the world rely on NBW to deliver exceptional performance and reliability.

Innovative Container Making Solutions for Your Packaging Needs

Container Making Company Announces Expansion PlansContainer making is a crucial aspect of the packaging industry, and one company is taking significant steps to expand its operations in order to meet the growing demand for its products. With a strong focus on quality and innovation, [Company] is making waves in the industry, and its expansion plans are set to solidify its position as a leader in the container making business.Established in [year], [Company] has quickly established itself as a trusted name in the packaging industry. With a commitment to producing high-quality containers and a dedication to meeting the needs of its customers, the company has experienced rapid growth in recent years. Its state-of-the-art manufacturing facilities and skilled team of professionals have allowed [Company] to offer a wide range of container options, catering to the diverse needs of various industries.The company's expansion plans come at a time when the demand for containers is on the rise. As more businesses recognize the importance of packaging in brand identity and product protection, the need for high-quality, reliable containers has never been greater. [Company] is well-positioned to capitalize on this growing demand, and its expansion plans will allow it to further solidify its presence in the market.In order to accommodate its growth and meet the increasing demand for its products, [Company] has announced plans to build a new, state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and machinery, allowing the company to increase its production capacity and streamline its operations. By doing so, [Company] aims to not only meet the current demand for its containers but also to prepare for future growth in the industry.In addition to the new manufacturing facility, [Company] also plans to expand its product line to offer even more options to its customers. With a focus on innovation and customer satisfaction, the company is committed to developing new and improved container solutions that meet the evolving needs of its clients. By expanding its product line, [Company] aims to become a one-stop shop for all container needs, further solidifying its position as a market leader.The expansion plans have generated excitement within the company and the industry as a whole. [Company] is known for its commitment to quality, innovation, and customer satisfaction, and the company's expansion plans are a testament to its dedication to these values. The new manufacturing facility and expanded product line will not only allow the company to better serve its existing customers but also attract new clients who are seeking high-quality container solutions.As the company prepares for this significant expansion, it remains committed to its core values and mission. [Company] is dedicated to producing containers that meet the highest standards of quality and performance, and its expansion plans are a reflection of this dedication. By investing in new technology, machinery, and product development, the company is positioning itself for long-term success in the container making business.Overall, the expansion plans announced by [Company] are set to further solidify the company's position as a leader in the container making industry. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for its products and continue to thrive in the industry. As the new manufacturing facility takes shape and the product line expands, [Company] is poised to make an even greater impact on the container making business.

Efficient and Automated Bread Packaging Machine for your Business

Bread Packaging Machine Revolutionizes the Baking IndustryThe baking industry has seen a significant shift in recent years with the introduction of innovative technologies that have transformed the way bread is produced and packaged. One such groundbreaking development is the Bread Packaging Machine, a state-of-the-art device that has revolutionized the packaging process for bakeries and food manufacturers.The Bread Packaging Machine, designed and manufactured by a leading provider of food processing and packaging solutions, has quickly gained recognition for its cutting-edge features and unparalleled efficiency. The machine is capable of seamlessly packaging a wide variety of bread products, including loaves, rolls, baguettes, and buns, with precision and speed. This level of versatility has made it a go-to choice for bakeries looking to streamline their packaging operations and meet the growing demand for packaged bread products.One of the key advantages of the Bread Packaging Machine is its ability to maintain the freshness and quality of the bread while extending its shelf life. The machine utilizes advanced packaging techniques that ensure proper sealing and protection, effectively preserving the taste, texture, and aroma of the bread. This has been a game-changer for bakeries and food manufacturers, allowing them to deliver consistently high-quality products to consumers while reducing food waste.In addition to its impressive performance, the Bread Packaging Machine is also lauded for its user-friendly design and intuitive operation. Equipped with a user-friendly interface and customizable settings, the machine can be easily adapted to meet the specific packaging requirements of different bread products. Its automated functions and advanced controls further contribute to a smooth and efficient packaging process, saving time and labor costs for businesses.Furthermore, the Bread Packaging Machine is designed with a focus on sustainability, incorporating eco-friendly materials and energy-efficient features. This aligns with the growing demand for sustainable packaging solutions within the food industry and reflects the company's commitment to environmental responsibility. By reducing the use of plastic and minimizing energy consumption, the machine helps businesses lower their carbon footprint and contribute to a more sustainable future.The introduction of the Bread Packaging Machine has not only transformed the packaging process for bread products but has also had a significant impact on the overall operations of bakeries and food manufacturers. With its ability to increase productivity, improve product quality, and reduce waste, the machine has become a valuable asset for businesses aiming to stay competitive in the market.As the demand for packaged bread products continues to grow, the Bread Packaging Machine has positioned itself as a crucial tool for businesses looking to meet consumer expectations and stay ahead of the competition. Its innovative technology and proven performance have set a new standard for bread packaging, driving the industry towards greater efficiency and sustainability.In conclusion, the Bread Packaging Machine has emerged as a game-changing solution for the baking industry, offering a combination of advanced technology, user-friendly design, and sustainable practices. Its impact on the production and packaging of bread products has been nothing short of transformative, and its continued presence is expected to shape the future of the industry for years to come. With its ability to optimize operations, improve product quality, and reduce environmental impact, the Bread Packaging Machine stands as a testament to the power of innovation in driving positive change within the food industry.

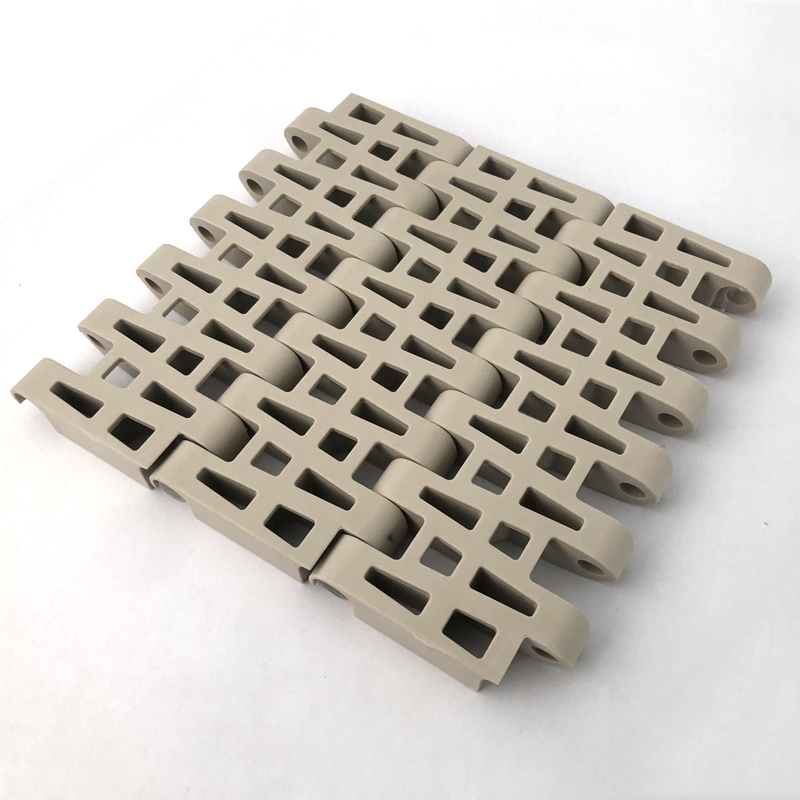

Discover the Versatility and Benefits of Modular Plastic Conveyor Belts in Various Industries

Modular Plastic Conveyor Belt Revolutionizes Material Handling IndustryIn today's rapidly evolving industrial landscape, many companies are turning to innovative solutions to optimize their operations and increase productivity. One such solution that has been gaining significant traction is the Modular Plastic Conveyor Belt, a cutting-edge technology that has revolutionized the material handling industry.Conventional conveyor belts have long been a staple in manufacturing and distribution centers, facilitating the movement of goods from one point to another. However, these traditional conveyor belts often suffer from limitations such as high maintenance costs, limited flexibility, and frequent downtime. With the introduction of the Modular Plastic Conveyor Belt, these issues are effectively addressed, paving the way for enhanced efficiency and increased profitability.The Modular Plastic Conveyor Belt is manufactured by [Company Name], a globally recognized leader in material handling solutions. With their extensive experience and commitment to excellence, the company has developed a conveyor belt system that offers extraordinary performance and versatility.Unlike traditional conveyor belts that consist of a single continuous loop, the Modular Plastic Conveyor Belt is composed of interlocking plastic modules. These modules are seamlessly connected, enabling the conveyor to be easily customized to fit any application or desired layout. This modular design also facilitates effortless repairs and replacements, significantly reducing maintenance costs and equipment downtime.The versatility of the Modular Plastic Conveyor Belt is further amplified by its ability to withstand extreme temperatures, corrosive environments, and heavy loads. The belt's durable plastic construction ensures optimal performance even in the most challenging conditions, making it an ideal choice for a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics.In addition to its outstanding functionality, the Modular Plastic Conveyor Belt also boasts several innovative features that contribute to improved efficiency. The belt incorporates a low-friction surface, reducing energy consumption and enhancing the overall lifespan of the system. It also features an enhanced load-carrying capacity, allowing for greater throughput and maximizing productivity.Another key advantage of the Modular Plastic Conveyor Belt is its ease of cleaning and maintenance. Traditional conveyor belts often require extensive cleaning and lubrication, leading to prolonged downtime. However, the modular design of this advanced conveyor system allows for quick and hassle-free cleaning, minimizing production interruptions and ensuring compliance with stringent hygiene standards.Furthermore, the Modular Plastic Conveyor Belt offers a safer working environment for employees. Its slip-resistant surface prevents accidental falls and injuries, while the interlocking modules reduce the risk of entrapment and provide added stability during operation.The adoption of the Modular Plastic Conveyor Belt has already brought tangible benefits to numerous companies across various industries. Many have reported significant improvements in their production efficiency, reduced maintenance costs, and enhanced overall profitability. As a result, an increasing number of businesses are recognizing this revolutionary technology as a game-changer in the material handling industry.In conclusion, the Modular Plastic Conveyor Belt developed by [Company Name] has brought about a paradigm shift in the material handling industry. Its modular design, exceptional performance, and versatility have enabled businesses to optimize their operations, increase productivity, and ultimately achieve greater profitability. As this cutting-edge technology continues to evolve, it is expected to reshape the future of material handling, setting new benchmarks for efficiency and reliability.