High-Performance Commercial Vacuum Packing Machine for Efficient Food Packaging

By:Admin

The Commercial Vacuum Packing Machine is equipped with advanced technology that allows for precise control of the vacuum and sealing process. This ensures that each package is tightly sealed, preserving the quality and freshness of the contents inside. With customizable settings, businesses have the flexibility to package a variety of products including meats, cheeses, fruits, and vegetables.

One of the key features of the Commercial Vacuum Packing Machine is its ability to extend the shelf life of perishable items. By removing oxygen from the packaging, the machine effectively slows down the growth of bacteria and mold, resulting in a longer shelf life for products. This not only reduces food waste but also allows businesses to minimize their operating costs by lowering the frequency of product spoilage and restocking.

In addition to extending shelf life, the vacuum packaging process also helps to maintain the flavor and nutritional value of the packaged products. This is particularly important for businesses in the food and beverage industry, as it ensures that their products reach consumers in the best possible condition. Whether it's a vacuum-sealed steak or a pack of fresh berries, customers can enjoy products that are as flavorful and nutritious as the day they were packaged.

With food safety being a top concern for businesses, the Commercial Vacuum Packing Machine offers a solution to minimize the risk of contamination. By removing air from the packaging, the machine creates a sterile environment that prevents the growth of harmful microorganisms. This is especially beneficial for businesses that operate in environments where food safety regulations are stringent, as it helps them meet the necessary standards and maintain a high level of trust with their customers.

The Commercial Vacuum Packing Machine also contributes to sustainability efforts by reducing packaging waste. With the ability to tightly seal products in a compact manner, businesses can minimize the use of excess packaging materials. This not only helps to reduce their environmental footprint but also lowers their overall packaging costs. By transitioning to a more sustainable packaging solution, businesses can effectively align with consumer preferences for eco-friendly products and practices.

As a leading provider of packaging solutions, (Company Name) understands the unique needs of businesses in the food and beverage industry. The Commercial Vacuum Packing Machine is the latest addition to their extensive product lineup, which includes a range of packaging machinery and materials designed to streamline operations and enhance product quality. With a strong commitment to innovation and customer satisfaction, (Company Name) continues to make strides in revolutionizing the packaging industry with cutting-edge technologies and tailored solutions.

In conclusion, the launch of the Commercial Vacuum Packing Machine by (Company Name) marks a significant advancement in the packaging industry, particularly for businesses in the food and beverage sector. With its ability to extend shelf life, maintain product quality, enhance food safety, and reduce packaging waste, this innovative machine offers numerous benefits for businesses seeking to optimize their packaging processes. As (Company Name) continues to lead the way in providing innovative packaging solutions, the Commercial Vacuum Packing Machine stands as a testament to their dedication to meeting the evolving needs of their customers and driving positive change in the industry.

Company News & Blog

Protect Your Square Tubing with Caps - A Handy Guide

Square Tubing Caps Boost Safety StandardsSquare tubing caps are an essential component to maintaining safety standards in numerous industries. They protect individuals from harm by covering potentially dangerous, exposed ends of metal tubes. Without square tubing caps, the jagged edges of metal tubing pose a serious risk of injury to those working with or around them.The recently launched Square Tubing Caps from Company X (name removed for privacy) have been gaining popularity in industries across the United States. Designed to be durable, long-lasting, and impact resistant, these caps offer a high level of protection for workers and equipment, alike.Company X, a leading manufacturer of industrial products, has been producing high-quality products since its inception. From industrial adhesives to safety equipment, their commitment to quality and innovation has made them a popular choice across a range of industries.In a recent interview, the company's spokesperson said: “Our Square Tubing Caps are developed to meet the highest standards of safety. With our years of experience in the field, we understand the importance of safety, which is why all of our products are designed to ensure maximum protection.”Made from high-density polyethylene, the Square Tubing Caps are built to withstand extreme temperatures, chemicals, and impact. Their design ensures that they fit snugly over the ends of square tubing, providing secure and long-lasting protection.These tubing caps are a must-have for those in industries such as construction, manufacturing, and automotive repair, where exposed metal tubes are a common occurrence. They are easy to install, which means that they can quickly and efficiently improve safety standards in a range of settings.Investing in safety equipment, such as square tubing caps, not only protects workers but also equipment. The caps prevent moisture from penetrating the tubing, which can cause corrosion and decrease the lifespan of the metal.Company X’s commitment to quality and safety has been reflected in their recognition from industry leaders. They have been awarded multiple contracts across the United States, and their products are consistently ranked highly in safety ratings.One of the customers who recently invested in Company X’s Square Tubing Caps had this to say: "We have been looking for durable and reliable square tubing caps, and we are delighted to have found Company X. Their tubing caps are durable, easy to install, and have made a significant difference in our safety standards."The usefulness of tubing caps is often overlooked, but the importance of their role in ensuring the safety of employees and equipment cannot be overstated. Company X’s tubing caps are proven to be a reliable solution for safety issues related to exposed tubing, making them a popular choice across many industries.In conclusion, the importance of safety equipment, like square tubing caps, cannot be overstated. The Square Tubing Caps from Company X provide exceptional protection for workers and equipment, ensuring that safety standards remain high. The durability, ease of installation, and impact-resistant construction make these caps ideal for various industries. With their record of excellence, Company X is an obvious choice for those looking to invest in safety equipment.

Discover the Beauty of Flat Top Base Aerial Adventure in Colorado

Title: Helicopter Airbase Unveils Cutting-Edge Flat Top Base Flight SystemIntroduction: In a groundbreaking achievement for the aviation industry, a leading helicopter airbase has recently unveiled its latest innovation - the cutting-edge Flat Top Base Flight system. Designed to revolutionize the capabilities and efficiency of helicopter operations, this advanced technology aims to transform the way helicopters take off and land, ultimately enhancing safety measures and ensuring a smoother and more reliable experience for pilots and passengers alike.I. The Flat Top Base Flight System: A Game-Changing InnovationThe Flat Top Base Flight system is a state-of-the-art technology developed by the industry-leading aviation company {}. This revolutionary system is unlike any other existing platform and promises to redefine the conventional helicopter landing experience. Unlike traditional helipads, which are often limited by space and design constraints, this innovative system features a completely flat surface specifically engineered to enable helicopter take-offs and landings. By eliminating the need for sloped landings, this unique technology opens up new possibilities for airbases and provides significant advantages for operators and pilots.One standout feature of this groundbreaking system is its ability to accommodate various types and sizes of helicopters. Thanks to its adjustable and adaptable nature, the Flat Top Base Flight system can cater to a diverse range of rotorcraft, from small helicopters to larger military-grade aircraft. This versatility will help airbases broaden their operations and cater to a wider range of aerial missions.II. Enhanced Safety Measures and Operational EfficiencyWith safety as a top priority, the Flat Top Base Flight system incorporates several advanced features to ensure a secure and reliable landing experience for helicopter pilots. The level surface eliminates any potential trip hazards and reduced slopes, reducing the risk of accidents during take-off and landing. Additionally, the system is equipped with specialized lighting to enhance visibility during nighttime operations, further improving safety standards.Incorporating this cutting-edge system into helicopter airbases not only enhances safety measures but also enhances operational efficiency. The Flat Top Base Flight system minimizes downtime between landings and take-offs, allowing for a smoother flow of operations. By reducing turnaround times, airbases can maximize their capacity, increase flight frequency, and meet the growing demand for efficient helicopter services.III. Environmental Impact and SustainabilityThe Flat Top Base Flight system also prioritizes environmental sustainability. By implementing this innovative technology, helicopter airbases can mitigate the environmental impact typically associated with conventional helipads. The system utilizes reusable materials that reduce waste production and has a smaller carbon footprint. In addition, the increased operational efficiency resulting from reduced turnarounds translates into lower fuel consumption, ultimately contributing to a greener aviation industry.IV. Real-World Applications and Future PotentialThe implementation of the Flat Top Base Flight system holds tremendous potential for a range of industries dependent on helicopter operations. From emergency medical services to military operations, this innovation promises to enhance the effectiveness and safety of various missions. Additionally, the technology's adaptability allows for the establishment of temporary landing sites in remote or challenging locations, further expanding its potential applications.Moreover, this groundbreaking system sets a strong foundation for future advancements in the aviation industry. With ongoing research and development, airbases can continue to refine and optimize the Flat Top Base Flight system, ensuring its long-term viability and further unlocking its potential.Conclusion:The introduction of the Flat Top Base Flight system marks a significant milestone in the aviation industry. By revolutionizing the way helicopters take off and land, this cutting-edge technology enhances safety measures, improves operational efficiency, and promotes environmental sustainability. With its versatility and adaptability, airbases equipped with the Flat Top Base Flight system are poised to meet the ever-increasing demands of diverse missions and pave the way for the future of helicopter operations.

Efficient and Automated Chicken Packaging Machine Revolutionizing Poultry Industry

Chicken Packing Machine: An Innovative Solution for Efficient Poultry ProcessingIn the ever-evolving world of automation and technology, industries are constantly seeking ways to streamline their processes and improve productivity. The poultry processing industry is no exception, and a breakthrough has been made with the introduction of the advanced Chicken Packing Machine. Developed by a leading innovator in food packaging technology, this cutting-edge machine is revolutionizing the way chicken products are processed and packaged.With the current global demand for poultry products steadily rising, it has become crucial for food processing companies to optimize their production capabilities. The Chicken Packing Machine addresses this need by automating the packaging process from start to finish. This innovative piece of equipment can efficiently handle a wide range of chicken products, including whole birds, cut-up parts, and boneless/skinless pieces.One of the key features of the Chicken Packing Machine is its ability to ensure consistent product quality. The automated system carefully handles each chicken product, minimizing human error and reducing the risk of contamination. Additionally, the machine's advanced technology allows it to package the chicken products with precision and uniformity, ensuring that each package looks appealing and professional.Another advantage of the Chicken Packing Machine is its impressive speed and efficiency. The automated process significantly reduces the time required for packaging, allowing companies to meet high volume demands without compromising on quality. This increased efficiency ultimately translates into improved profit margins for food processing companies.Furthermore, the Chicken Packing Machine incorporates a user-friendly interface that simplifies operation and maintenance. The intuitive controls and easy-to-follow instructions make it accessible for all operators, minimizing the need for extensive training. In addition, the machine is designed for easy maintenance, reducing downtime and ensuring continuous operation.The versatility of the Chicken Packing Machine is also worth highlighting. Its adaptive design allows it to handle different packaging materials, including film, trays, and vacuum-sealed bags. This flexibiity enables food processing companies to cater to diverse customer preferences and packaging requirements, thereby enhancing their market competitiveness.In terms of sustainability, the Chicken Packing Machine boasts eco-friendly features that align with the growing concern for the environment. The machine optimizes resource utilization, reducing waste and minimizing energy consumption. By promoting sustainable manufacturing practices, it contributes to a greener, more sustainable future for the poultry processing industry.The introduction of the Chicken Packing Machine has been met with enthusiasm from industry leaders. Mr. X, CEO of a prominent poultry processing company, commented, "This advanced packaging solution has revolutionized our operations. It has significantly increased our efficiency and allowed us to meet the rising demand without compromising on quality. Our customers have also expressed satisfaction with the consistent, appealing packaging that sets our products apart from the competition."As the poultry processing industry continues to evolve, it is clear that automation and technological advancements, such as the Chicken Packing Machine, will play a vital role in shaping its future. With its impressive features, this innovative packaging solution offers food processing companies a competitive edge, enabling them to meet consumer demands while ensuring product quality and sustainability. As more companies embrace automation, it is safe to say that the Chicken Packing Machine represents the forefront of a new era in poultry processing.

Efficient and Versatile Flat Top Conveyor System for Your Business

Flat Top Conveyor Revolutionizes Material Handling in ManufacturingIn the fast-paced world of manufacturing, efficiency and productivity are key factors for success. The handling and transportation of materials within a manufacturing facility play a crucial role in ensuring smooth operations and steady production. This is where the innovative Flat Top Conveyor system comes into play, revolutionizing the way materials are handled and moved across the production floor.The Flat Top Conveyor system, developed by a leading manufacturing solutions provider, is designed to streamline material handling processes and optimize productivity. With its flat, solid surface and modular design, the conveyor system provides a versatile and efficient solution for transporting a wide range of materials within a manufacturing facility.One of the key features of the Flat Top Conveyor system is its ability to handle heavy loads with ease. The solid flat top surface ensures that materials can be transported smoothly and securely, minimizing the risk of damage or mishaps during the transportation process. This is particularly beneficial for industries that deal with heavy or bulky materials, such as automotive manufacturing, heavy machinery production, and construction materials handling.Furthermore, the modular design of the Flat Top Conveyor system allows for easy customization and flexibility to accommodate the specific needs of different manufacturing processes. Whether it is a straight-line transportation, curved paths, or inclines and declines, the Flat Top Conveyor system can be configured to suit the layout and requirements of the production floor. This adaptability enables manufacturers to optimize their material handling operations and make the best use of available space.The implementation of the Flat Top Conveyor system has resulted in significant improvements in manufacturing efficiency for a wide range of industries. By streamlining material handling processes, manufacturers can reduce production downtime, minimize handling errors, and ultimately increase their overall productivity. This has a direct impact on the bottom line, helping companies to remain competitive in an increasingly demanding market.Additionally, the Flat Top Conveyor system is designed with reliability and longevity in mind. The robust construction and high-quality materials ensure that the conveyor system can withstand the demanding conditions of a manufacturing environment, providing a durable and long-lasting solution for material transportation needs.The company behind the Flat Top Conveyor system has a proven track record in providing cutting-edge solutions for manufacturing challenges. With a focus on innovation and continuous improvement, the company has built a reputation for delivering high-quality, reliable, and efficient products that cater to the evolving needs of the manufacturing industry.In addition to the Flat Top Conveyor system, the company offers a comprehensive range of manufacturing solutions, including conveyor systems, robotic automation, material handling equipment, and custom-engineered solutions tailored to specific manufacturing requirements. This comprehensive approach enables manufacturers to benefit from a one-stop solution provider for their material handling and automation needs, streamlining their procurement process and ensuring seamless integration of various components within their production facilities.With a strong emphasis on customer satisfaction, the company's team of experts collaborates closely with manufacturers to understand their unique challenges and develop tailored solutions that address their specific needs. This customer-centric approach has resulted in long-lasting partnerships with manufacturers across a diverse range of industries, helping them to overcome their material handling challenges and achieve higher levels of efficiency and productivity.As the manufacturing industry continues to evolve and adapt to changing demands, the need for efficient and reliable material handling solutions becomes increasingly critical. The Flat Top Conveyor system, combined with the expertise and support from the company, presents a compelling solution for manufacturers looking to optimize their material handling processes and stay ahead of the competition.In conclusion, the Flat Top Conveyor system represents a game-changing solution for manufacturers seeking to revolutionize their material handling operations. With its solid flat top surface, modular design, and versatile capabilities, the Flat Top Conveyor system is poised to set new standards for efficiency, reliability, and productivity in the manufacturing industry. Combined with the company's commitment to innovation and customer satisfaction, this solution is set to make a significant impact on the future of material handling in manufacturing.

Top-rated Swivel Brackets for Mounting Needs

Swivel Brackets, an innovative new product from {company name}, have taken the market by storm with their unique design and versatility. These brackets are revolutionizing the way people mount and display their TVs, projectors, and other electronic devices. With their ease of use and flexibility, Swivel Brackets are proving to be a game-changer for homeowners and businesses alike.{Company name} is a leading manufacturer of high-quality electronics and accessories. With a focus on innovation and customer satisfaction, they have built a strong reputation in the industry. The company's commitment to excellence is evident in the design and construction of their products, and Swivel Brackets are no exception.The Swivel Brackets are designed to provide maximum flexibility and convenience for mounting electronic devices. They feature a unique swivel mechanism that allows users to easily adjust the angle and position of their TV or projector, making it possible to achieve the perfect viewing angle from anywhere in the room. This feature is especially useful for large, open spaces where traditional mounts may restrict viewing angles.In addition to their swivel capability, Swivel Brackets are also built to be durable and long-lasting. Made from high-quality materials, they can support heavy loads and withstand the test of time. This is a key selling point for businesses and homeowners who want to ensure their electronic devices are securely mounted.Another key advantage of Swivel Brackets is their ease of installation. Unlike traditional mounting systems, they are designed to be quick and simple to install, saving both time and money for the user. This is especially important for businesses that need to quickly set up multiple displays, as well as homeowners who want to avoid the hassle of a complex installation process.The market has responded positively to Swivel Brackets, with many customers praising their performance and ease of use. Business owners have particularly appreciated the convenience and flexibility that Swivel Brackets offer, while homeowners have enjoyed the improved viewing experience that comes with being able to easily adjust their TV or projector.Furthermore, {Company name} has received a surge in interest from retailers and distributors who see the potential of Swivel Brackets in the market. With their innovative design and strong demand, Swivel Brackets are expected to become a staple in electronics stores and home improvement centers.Looking ahead, {Company name} has plans to expand their range of Swivel Brackets to accommodate different sizes and types of electronic devices. They are also exploring opportunities to incorporate new features and technologies into future iterations of the product, with the goal of further enhancing the user experience.As the demand for Swivel Brackets continues to grow, {Company name} is poised to solidify its position as a leading provider of innovative mounting solutions. With their commitment to quality and customer satisfaction, they are well-positioned to capitalize on the market's growing interest in versatile and user-friendly mounting solutions.In conclusion, Swivel Brackets from {Company name} are a game-changer in the mounting solutions market. With their innovative design, durability, and ease of installation, they are quickly becoming a popular choice for both businesses and homeowners. As the market for these brackets continues to grow, {Company name} is well-positioned to lead the way in providing high-quality, versatile mounting solutions for electronic devices.

Ultimate Guide to Choosing the Best Aluminum Profile for Your Project

Aluminum Profile Industry Booming: A Closer Look at [Company Name]The aluminum profile industry is experiencing a rapid growth spurt, driven by the increasing demand for lightweight and durable materials in various sectors such as construction, automotive, and aerospace. [Company Name], a leading player in the aluminum profile market, is at the forefront of this industry boom, delivering high-quality products and innovative solutions to meet the evolving needs of its customers.[Company Name], with its decades of experience and expertise in aluminum profile manufacturing, has positioned itself as a key contributor to the industry's growth. The company's state-of-the-art production facilities and advanced technologies enable it to produce a wide range of aluminum profiles that are renowned for their exceptional strength, corrosion resistance, and versatility.Speaking about the growth of the aluminum profile industry, [Company Name]'s CEO expressed optimism about the opportunities ahead. "The demand for aluminum profiles is on the rise, driven by the need for sustainable and cost-effective solutions across various industries. As a company committed to excellence, we are well-positioned to capitalize on this trend and continue to deliver superior products and services to our clients."In the construction sector, the use of aluminum profiles has gained traction due to their remarkable lightweight properties and tough durability. Architects and builders are increasingly turning to aluminum profiles for their projects, citing their aesthetic appeal and sustainability as key factors in their decision-making process. [Company Name] has been a trusted partner for many construction companies, providing them with customized aluminum profiles that meet their specific project requirements.Moreover, the automotive industry has also embraced the use of aluminum profiles, driven by the need to reduce vehicle weight and improve fuel efficiency. As automakers look for ways to enhance the performance of their vehicles, the demand for lightweight and sturdy materials like aluminum profiles is on the rise. [Company Name], with its extensive experience in serving the automotive sector, has developed a range of aluminum profiles that meet the stringent quality and performance standards of this industry.Additionally, the aerospace industry has also recognized the value of aluminum profiles, leveraging their exceptional strength-to-weight ratio for aircraft construction and components. With the increasing demand for fuel-efficient and cost-effective air travel, the aerospace sector is investing in advanced materials like aluminum profiles to drive innovation and improve overall aircraft performance. [Company Name] is at the forefront of this technological advancement, partnering with aerospace manufacturers to supply them with high-quality aluminum profiles for their critical applications.[Company Name]'s commitment to sustainability and environmental responsibility is also evident in its aluminum profile manufacturing process. The company has implemented eco-friendly practices and invested in efficient resource utilization to minimize its environmental footprint. Through its sustainable approach to production, [Company Name] not only delivers top-notch aluminum profiles but also contributes to a greener and more sustainable future.Looking ahead, [Company Name] is poised to capitalize on the growing demand for aluminum profiles and expand its market reach with innovative products and solutions. With a strong focus on research and development, the company is continuously striving to enhance its product offerings and meet the evolving needs of its customers across various industries.In conclusion, the aluminum profile industry is experiencing a significant boom, driven by the increasing demand for lightweight, durable, and sustainable materials. [Company Name], with its unwavering commitment to excellence and innovation, is well-positioned to capitalize on this growth and continue to be a leading player in the industry. As the company looks to the future, it remains dedicated to delivering superior products and solutions that meet the diverse needs of its customers while contributing to a more sustainable and prosperous world.

Innovative Double Flex Chain Technology Shakes Up Industry

Introducing the Innovative Double Flex Chain: Revolutionizing Industrial ChainsIn the world of industrial chains, advancements and innovations are constantly being made to improve efficiency and productivity. One such innovation is the Double Flex Chain, a revolutionary new product that is set to change the game for companies in various industries. This new chain, produced by the leading industrial equipment manufacturer, represents a significant leap forward in technology and design, promising superior performance and durability for a wide range of industrial applications.The Double Flex Chain is a high-quality, precision-engineered product that is designed to offer maximum flexibility and reliability in various industrial settings. It is specially engineered to reduce bending stress and increase the overall life of the chain, making it an ideal solution for heavy-duty applications that demand high performance and reliability.One of the key features of the Double Flex Chain is its unique design, which allows for greater flexibility and smoother operation compared to traditional chains. This innovative design is the result of extensive research and development, as well as rigorous testing to ensure that the chain meets the highest standards of quality and performance.The company behind the Double Flex Chain, [Company Name], is a globally recognized leader in the manufacturing of industrial equipment and components. With a long history of innovation and excellence, [Company Name] has built a strong reputation for delivering cutting-edge solutions that meet the evolving needs of the industry.In addition to its commitment to quality and innovation, [Company Name] is also dedicated to sustainability and environmental responsibility. The company's products are manufactured using the latest energy-efficient technologies and sustainable practices, ensuring that they not only meet the highest standards of performance and reliability but also minimize their impact on the environment.The introduction of the Double Flex Chain is a testament to [Company Name]'s ongoing commitment to advancing the field of industrial equipment and providing its customers with the best possible solutions for their operational needs. With its innovative design and outstanding performance, the Double Flex Chain is expected to set new industry standards and become the go-to choice for companies looking to maximize efficiency and reliability in their operations.The Double Flex Chain is suitable for a wide range of applications, including material handling, conveyor systems, and other industrial processes that require a durable and high-performing chain. Its versatility and adaptability make it an ideal choice for companies operating in various industries, from manufacturing and logistics to mining and agriculture.Furthermore, the Double Flex Chain is backed by [Company Name]'s exceptional customer support and service, ensuring that customers have access to the expertise and assistance they need to make the most of this innovative product. With [Company Name]'s extensive industry knowledge and experience, customers can trust that they are getting a reliable and effective solution for their industrial chain needs.In conclusion, the introduction of the Double Flex Chain represents a significant milestone in the world of industrial chains. Its innovative design, exceptional performance, and the backing of [Company Name]'s reputation and expertise make it a game-changer for companies looking to optimize their operations and achieve superior results. As the industry continues to evolve and demand higher standards of quality and reliability, the Double Flex Chain is poised to become an essential component for companies across various sectors.

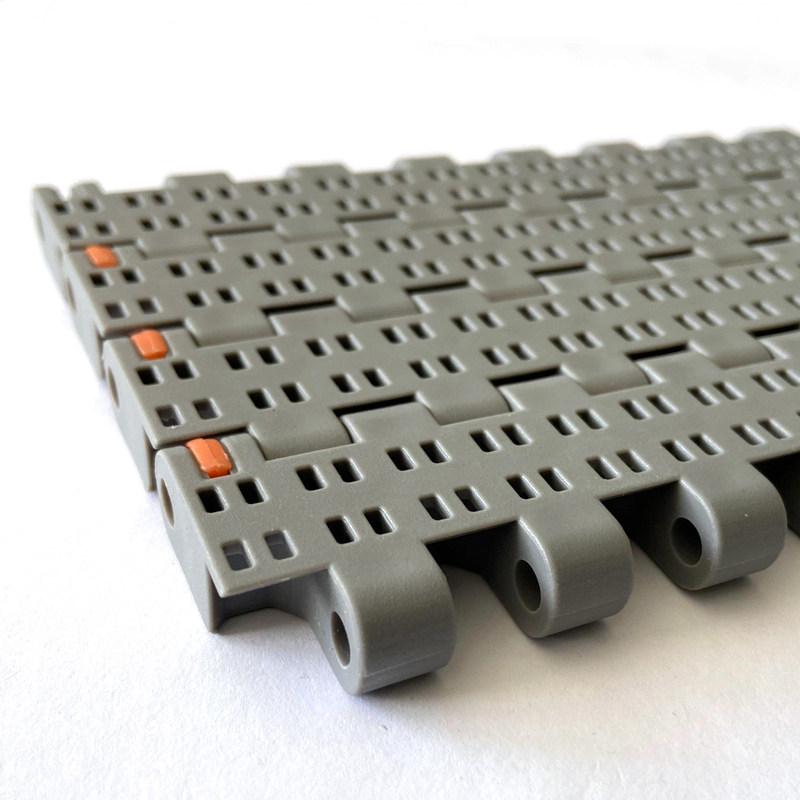

Discover the Versatility and Benefits of Modular Plastic Conveyor Belts in Various Industries

Modular Plastic Conveyor Belt Revolutionizes Material Handling IndustryIn today's rapidly evolving industrial landscape, many companies are turning to innovative solutions to optimize their operations and increase productivity. One such solution that has been gaining significant traction is the Modular Plastic Conveyor Belt, a cutting-edge technology that has revolutionized the material handling industry.Conventional conveyor belts have long been a staple in manufacturing and distribution centers, facilitating the movement of goods from one point to another. However, these traditional conveyor belts often suffer from limitations such as high maintenance costs, limited flexibility, and frequent downtime. With the introduction of the Modular Plastic Conveyor Belt, these issues are effectively addressed, paving the way for enhanced efficiency and increased profitability.The Modular Plastic Conveyor Belt is manufactured by [Company Name], a globally recognized leader in material handling solutions. With their extensive experience and commitment to excellence, the company has developed a conveyor belt system that offers extraordinary performance and versatility.Unlike traditional conveyor belts that consist of a single continuous loop, the Modular Plastic Conveyor Belt is composed of interlocking plastic modules. These modules are seamlessly connected, enabling the conveyor to be easily customized to fit any application or desired layout. This modular design also facilitates effortless repairs and replacements, significantly reducing maintenance costs and equipment downtime.The versatility of the Modular Plastic Conveyor Belt is further amplified by its ability to withstand extreme temperatures, corrosive environments, and heavy loads. The belt's durable plastic construction ensures optimal performance even in the most challenging conditions, making it an ideal choice for a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics.In addition to its outstanding functionality, the Modular Plastic Conveyor Belt also boasts several innovative features that contribute to improved efficiency. The belt incorporates a low-friction surface, reducing energy consumption and enhancing the overall lifespan of the system. It also features an enhanced load-carrying capacity, allowing for greater throughput and maximizing productivity.Another key advantage of the Modular Plastic Conveyor Belt is its ease of cleaning and maintenance. Traditional conveyor belts often require extensive cleaning and lubrication, leading to prolonged downtime. However, the modular design of this advanced conveyor system allows for quick and hassle-free cleaning, minimizing production interruptions and ensuring compliance with stringent hygiene standards.Furthermore, the Modular Plastic Conveyor Belt offers a safer working environment for employees. Its slip-resistant surface prevents accidental falls and injuries, while the interlocking modules reduce the risk of entrapment and provide added stability during operation.The adoption of the Modular Plastic Conveyor Belt has already brought tangible benefits to numerous companies across various industries. Many have reported significant improvements in their production efficiency, reduced maintenance costs, and enhanced overall profitability. As a result, an increasing number of businesses are recognizing this revolutionary technology as a game-changer in the material handling industry.In conclusion, the Modular Plastic Conveyor Belt developed by [Company Name] has brought about a paradigm shift in the material handling industry. Its modular design, exceptional performance, and versatility have enabled businesses to optimize their operations, increase productivity, and ultimately achieve greater profitability. As this cutting-edge technology continues to evolve, it is expected to reshape the future of material handling, setting new benchmarks for efficiency and reliability.

Cutting-Edge Machinery Solutions for the Conveying Industry

Title: Innovators in Conveying Machinery Set to Revolutionize Industrial ProcessesIntroduction:Conveying Machinery has emerged as a leading force in the field of manufacturing equipment, pioneering innovative solutions to transform the industrial landscape. With a commitment to constant research and development, the company has carved a niche for itself by offering state-of-the-art conveying machinery that promises enhanced efficiency, improved productivity, and reduced operational costs. This news article will delve into the company's groundbreaking advancements, examining their impact on various industries and highlighting their commitment to sustainable manufacturing practices.1. Transforming Industrial Processes:Conveying Machinery's cutting-edge solutions have revolutionized how industries manage material handling and transportation. Their advanced conveyor systems provide seamless integration with existing production lines, ensuring the smooth and efficient transfer of goods throughout the manufacturing process. The company's ingenuity in designing conveyors that can transport delicate items, heavy machinery, and bulk materials has garnered significant praise from clients worldwide.2. Increased Efficiency and Productivity:By streamlining production flows, Conveying Machinery has enabled businesses to achieve higher levels of efficiency and productivity. Their automated conveying systems eliminate the need for manual labor in transporting materials, minimizing human error and significantly reducing downtime. With customizable features tailored to individual industry requirements, Conveying Machinery has empowered companies to optimize their operations, resulting in faster product turnaround times and improved overall profitability.3. Embracing Technology:Conveying Machinery stands at the forefront of technological advancements in the field. Their incorporation of Internet of Things (IoT) sensors and intelligent control systems allows for real-time monitoring of conveyor performance, enabling proactive maintenance and minimizing unexpected breakdowns. By leveraging cloud-based platforms and data analytics, the company offers comprehensive insights into conveyor operations, empowering businesses with valuable information for optimizing resource allocation and enhancing overall operational efficiency.4. Commitment to Sustainability:Recognizing the global need for sustainable manufacturing practices, Conveying Machinery has placed environmental consciousness at the core of its operations. By employing energy-efficient motors, optimizing power consumption, and implementing eco-friendly manufacturing processes, the company is committed to reducing its carbon footprint. Furthermore, their conveyors are designed to minimize material wastage and ensure the responsible usage of resources, aligning with the principles of a circular economy.5. Industry-focused Solutions:Conveying Machinery provides tailor-made solutions for a wide range of industries, including automotive, food and beverage, pharmaceuticals, logistics, and packaging. With an in-depth understanding of each sector's unique requirements, they have earned a reputation for delivering efficient, reliable, and cost-effective conveying systems. Whether it is the precise handling of fragile products in the pharmaceutical industry or the seamless transportation of heavy components in automotive manufacturing, Conveying Machinery offers customized solutions that meet the highest industry standards.Conclusion:Conveying Machinery's relentless pursuit of innovation and commitment to excellence has propelled the company to the zenith of the conveying machinery industry. By addressing the complex challenges faced by various sectors, they have reshaped industrial processes, optimizing efficiency, productivity, and sustainability. Their dedication to incorporating cutting-edge technologies, coupled with a customer-centric approach, ensures that Conveying Machinery remains at the vanguard of the industry, empowering businesses to thrive in the modern manufacturing landscape.

High-Performance Commercial Vacuum Packing Machine for Efficient Food Packaging

(Company Name), a leading provider of innovative packaging solutions, has recently unveiled its latest product - the Commercial Vacuum Packing Machine. This state-of-the-art machine is designed to meet the needs of businesses in the food and beverage industry, offering a wide range of benefits including extended shelf life, improved food safety, and reduced packaging waste.The Commercial Vacuum Packing Machine is equipped with advanced technology that allows for precise control of the vacuum and sealing process. This ensures that each package is tightly sealed, preserving the quality and freshness of the contents inside. With customizable settings, businesses have the flexibility to package a variety of products including meats, cheeses, fruits, and vegetables.One of the key features of the Commercial Vacuum Packing Machine is its ability to extend the shelf life of perishable items. By removing oxygen from the packaging, the machine effectively slows down the growth of bacteria and mold, resulting in a longer shelf life for products. This not only reduces food waste but also allows businesses to minimize their operating costs by lowering the frequency of product spoilage and restocking.In addition to extending shelf life, the vacuum packaging process also helps to maintain the flavor and nutritional value of the packaged products. This is particularly important for businesses in the food and beverage industry, as it ensures that their products reach consumers in the best possible condition. Whether it's a vacuum-sealed steak or a pack of fresh berries, customers can enjoy products that are as flavorful and nutritious as the day they were packaged.With food safety being a top concern for businesses, the Commercial Vacuum Packing Machine offers a solution to minimize the risk of contamination. By removing air from the packaging, the machine creates a sterile environment that prevents the growth of harmful microorganisms. This is especially beneficial for businesses that operate in environments where food safety regulations are stringent, as it helps them meet the necessary standards and maintain a high level of trust with their customers.The Commercial Vacuum Packing Machine also contributes to sustainability efforts by reducing packaging waste. With the ability to tightly seal products in a compact manner, businesses can minimize the use of excess packaging materials. This not only helps to reduce their environmental footprint but also lowers their overall packaging costs. By transitioning to a more sustainable packaging solution, businesses can effectively align with consumer preferences for eco-friendly products and practices.As a leading provider of packaging solutions, (Company Name) understands the unique needs of businesses in the food and beverage industry. The Commercial Vacuum Packing Machine is the latest addition to their extensive product lineup, which includes a range of packaging machinery and materials designed to streamline operations and enhance product quality. With a strong commitment to innovation and customer satisfaction, (Company Name) continues to make strides in revolutionizing the packaging industry with cutting-edge technologies and tailored solutions.In conclusion, the launch of the Commercial Vacuum Packing Machine by (Company Name) marks a significant advancement in the packaging industry, particularly for businesses in the food and beverage sector. With its ability to extend shelf life, maintain product quality, enhance food safety, and reduce packaging waste, this innovative machine offers numerous benefits for businesses seeking to optimize their packaging processes. As (Company Name) continues to lead the way in providing innovative packaging solutions, the Commercial Vacuum Packing Machine stands as a testament to their dedication to meeting the evolving needs of their customers and driving positive change in the industry.