High-speed Meal Tray Sealing Machine for Fresh Food Packaging

By:Admin

ABC Company, a leading provider of food packaging solutions, has recently introduced an innovative Meal Tray Sealing Machine that is set to revolutionize the food packaging industry. This state-of-the-art machine is designed to meet the growing demand for efficient and hygienic food packaging solutions, and is expected to offer significant benefits to food businesses and consumers alike.

The Meal Tray Sealing Machine is equipped with advanced technology and features that ensure airtight sealing of food trays, maintaining the freshness and quality of the packaged food. The machine is capable of sealing a wide range of tray sizes and shapes, making it highly versatile for different food packaging requirements. This is especially crucial for businesses that offer a variety of meal options, as the machine can accommodate the diverse needs of the food industry.

One of the key advantages of the Meal Tray Sealing Machine is its ability to enhance the shelf life of the packaged food. By sealing the trays in an airtight manner, the machine helps to prevent contamination and extend the freshness of the food, reducing food waste and ensuring that consumers receive high-quality products. This is particularly important for businesses that distribute pre-packaged meals or ready-to-eat food items, as it allows them to maintain the integrity of their products for a longer period of time.

In addition to extending shelf life, the Meal Tray Sealing Machine also offers remarkable efficiency and cost savings for food businesses. With its high-speed sealing capabilities, the machine can significantly increase the production output and streamline the packaging process, reducing the time and labor required for packaging operations. This is a major advantage for businesses looking to improve their operational efficiency and reduce packaging costs, as the machine offers a cost-effective solution for high-volume food packaging needs.

Furthermore, the Meal Tray Sealing Machine is designed with food safety and hygiene in mind, ensuring that the packaged food remains uncontaminated throughout the packaging process. The machine is equipped with sanitation features that maintain strict hygiene standards, minimizing the risk of bacterial contamination and ensuring that the food remains safe for consumption. This is especially important in light of increasing concerns about food safety and hygiene, as the machine provides reassurance to consumers that the packaged food meets the highest standards of quality and cleanliness.

The introduction of the Meal Tray Sealing Machine is a testament to ABC Company’s commitment to innovation and excellence in food packaging solutions. With a strong focus on meeting the evolving needs of the food industry, ABC Company has consistently delivered cutting-edge packaging technologies that offer tangible benefits to businesses and consumers. The Meal Tray Sealing Machine is a continuation of this tradition, providing a reliable and efficient solution for food businesses seeking to enhance their packaging capabilities and deliver superior products to the market.

As the food industry continues to evolve and adapt to changing consumer preferences and market dynamics, the demand for innovative packaging solutions is expected to grow. The Meal Tray Sealing Machine represents a significant advancement in food packaging technology, offering a versatile, efficient, and hygienic solution that addresses the key challenges faced by food businesses. With its potential to improve shelf life, increase efficiency, and ensure food safety, the machine is poised to make a substantial impact on the industry and set a new standard for food packaging excellence.

In conclusion, the introduction of the Meal Tray Sealing Machine by ABC Company marks a significant milestone in the advancement of food packaging technology. With its impressive features and benefits, the machine is set to redefine the standards for food packaging efficiency, quality, and hygiene, offering a compelling solution for businesses seeking to enhance their packaging capabilities. As the industry continues to embrace innovation and progress, the Meal Tray Sealing Machine is poised to play a crucial role in shaping the future of food packaging, delivering value to businesses and consumers alike.

Company News & Blog

Durable Plastic Square Pipe End Caps for Protection and Finishing

Square Pipe End Cap Plastic, an innovative product designed to provide protection and aesthetic appeal to square pipe ends, is gaining popularity in various industries. With its durable and versatile design, this product is becoming a staple in the construction, furniture, and manufacturing sectors.The Square Pipe End Cap Plastic is manufactured by a leading company in the field of industrial components. With a strong commitment to quality and innovation, the company has been providing premium products to its customers for decades. Their extensive experience and expertise in the industry have allowed them to develop a range of solutions to meet the diverse needs of their clients. This innovative product is just one example of their dedication to providing cutting-edge solutions to the market.The Square Pipe End Cap Plastic is designed to offer protection to square pipe ends, preventing damage from moisture, impact, and other environmental factors. Made from high-quality plastic materials, this product is highly durable and long-lasting. Its sleek and seamless design also enhances the overall appearance of the pipes, making it a popular choice for both functional and aesthetic purposes.One of the key features of the Square Pipe End Cap Plastic is its versatility. Available in various sizes and colors, this product can accommodate different types of square pipes and match the design requirements of different applications. Whether it is used in the construction of buildings, the manufacturing of furniture, or the production of industrial equipment, this product can be tailored to meet the specific needs of each customer.Furthermore, the installation process of the Square Pipe End Cap Plastic is simple and efficient. The product can be easily mounted onto the square pipe ends, providing a secure and tight fit. Its lightweight construction also adds to the ease of installation, making it a convenient solution for various industry professionals.In addition to its functional benefits, the Square Pipe End Cap Plastic also offers environmental advantages. Made from recyclable materials, this product aligns with sustainable practices and reduces the environmental impact of industrial operations. This aspect has resonated with environmentally conscious businesses and individuals, further contributing to the growing demand for this innovative solution.The company behind the Square Pipe End Cap Plastic takes pride in its commitment to customer satisfaction. They strive to provide exceptional service and support to ensure that their clients receive the best products for their specific needs. With a customer-centric approach, the company has built strong relationships with a wide network of businesses across different industries, positioning itself as a trusted partner in the supply of industrial components.As the demand for high-quality industrial components continues to rise, the company remains dedicated to innovation and excellence. Their ongoing research and development efforts aim to bring new and improved solutions to the market, further solidifying their position as a leader in the industry. The success of the Square Pipe End Cap Plastic is a testament to their ability to deliver products that meet the evolving needs of the market.In conclusion, the Square Pipe End Cap Plastic has emerged as a versatile and reliable solution for the protection and enhancement of square pipe ends. With its durable design, aesthetic appeal, and environmental benefits, this innovative product has gained traction across various industries. Coupled with the company's dedication to quality and customer satisfaction, the Square Pipe End Cap Plastic is set to continue making a positive impact in the industrial sector for years to come.

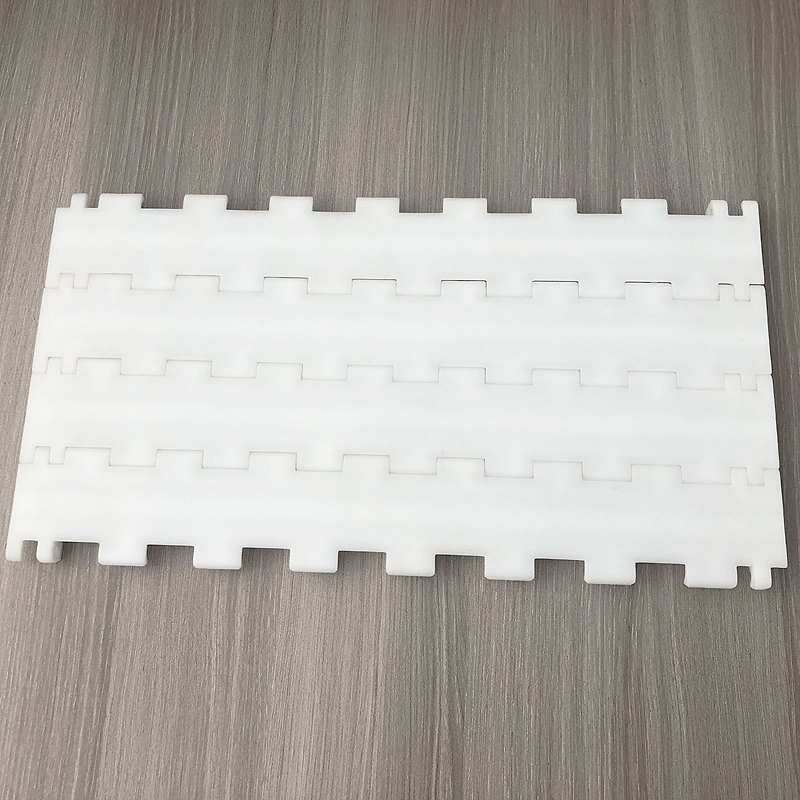

Essential Roller Guides for Efficient Chain Return Explained

Roller Guides for Chain Return Enhance Efficiency in Industrial WorkflowsIndustrial processes demand high levels of efficiency and precision, and every component plays a crucial role in ensuring smooth operations. One such component, often overlooked but critical in various industries, is the roller guide for chain return. These guides provide a reliable solution for maintaining the steady movement of chains, allowing for efficient operation of numerous applications, such as conveyors, material handling systems, and assembly lines.[Company Name], a leading provider of industrial automation solutions, recognizes the importance of roller guides for chain return and offers a versatile range of high-quality products. With their advanced engineering and proven technology, [Company Name] has been satisfying the needs of various industries, ranging from automotive and manufacturing to food processing and pharmaceuticals.Designed to minimize friction and maximize durability, [Company Name]'s roller guides ensure smooth chain movement, eliminating disruptions in the production line. By reducing chain wear and noise, these guides significantly extend the lifespan of chains, resulting in a more cost-effective solution for industry professionals.The roller guides' accurate tracking mechanism ensures that chains remain properly aligned, reducing the risk of derailment and improving safety in the workplace. This feature becomes particularly essential in applications where heavy loads are involved, eliminating any potential hazards or accidents.The versatility of [Company Name]'s roller guides allows them to be easily integrated into existing systems, eliminating the need for extensive modifications or replacements. Whether it is a conveyor belt or an automated assembly line, these guides ensure optimal chain performance while minimizing operational downtime. Thus, industries can seamlessly incorporate the roller guides into their existing workflows without disrupting their production cycles.Moreover, [Company Name] offers a range of roller guide options, allowing businesses to choose the most suitable guide based on their specific requirements. The guides are available in different sizes and materials, making it possible to accommodate various chain types and applications effectively. This flexibility ensures that the roller guides seamlessly adapt to the unique needs and demands of different industrial setups.In addition to their technical advantages, [Company Name]'s roller guides also come with exceptional after-sales support. The company’s commitment to customer satisfaction ensures that clients receive prompt assistance and guidance throughout the installation process. This personalized approach creates a long-term partnership, where businesses can rely on the expertise of [Company Name] in maintaining smooth operations.With the introduction of [Company Name]'s roller guides for chain return, industries across the board have witnessed improved efficiency and reliability. Companies can now focus on enhancing productivity and optimizing their operations, without worrying about chain performance or interruptions in the workflow.In conclusion, roller guides for chain return play a vital role in industrial processes, ensuring smooth operation and optimizing efficiency. [Company Name]'s innovative range of roller guides has proven to be a game-changer in numerous industries, enabling businesses to achieve their production goals while maintaining high levels of reliability and safety. By investing in these advanced roller guides, companies can enhance their operational performance and stay ahead in today's competitive market.

Effective Vibration Absorbing Feet for Heavy Machinery

[Headline]: Innovative Vibration Absorbing Feet Provide Enhanced Stability and Comfort[Subheading]: Company X Introduces Cutting-Edge Vibration Absorbing Feet for Increased Stability and Reduced Impact[date][City, State] - Company X, a renowned industry leader in equipment innovation, has unveiled their latest invention in the field of stability and comfort. With their revolutionary Vibration Absorbing Feet, the company aims to redefine standards of stability and comfort in a wide range of industries, benefiting professionals and consumers alike.The Vibration Absorbing Feet, proudly developed by Company X's team of expert engineers, are a breakthrough product capable of reducing vibrations, impact, and trembling effects experienced by individuals using various equipment, machinery, and appliances. These feet offer unparalleled stability and comfort, setting a new industry standard in reducing fatigue-related injuries and increasing efficiency.Equipped with advanced shock-absorbing technology, the Vibration Absorbing Feet actively combat excessive vibration, ensuring a firm and stable structure for a diverse range of applications. The feet are designed to absorb vibrations and transfer them away from the equipment, greatly minimizing the detrimental effects of vibrations on human operators and the surrounding environment.Not only do these innovative feet enhance stability, but they also significantly reduce impact, thereby safeguarding equipment from potential damage caused by excessive vibrations. By absorbing the energy generated by machinery, tools, or appliances, the Vibration Absorbing Feet mitigate wear and tear, leading to extended equipment lifespans and reduced maintenance costs. This revolutionary technology is poised to revolutionize industries such as construction, manufacturing, healthcare, and transportation, among others."We are thrilled to introduce our Vibration Absorbing Feet to the market," said [spokesperson name], a senior executive at Company X. "This innovation underscores our commitment to providing reliable, efficient, and safe solutions for professionals who rely on stability and reducing vibrations in their daily work. We are confident that our product will be highly sought-after, offering a superior alternative to traditional stabilizing measures."To further cater to the specific needs of various industries, Company X offers Vibration Absorbing Feet in different sizes, materials, and configurations. These customizable options ensure that the feet can be seamlessly integrated into a wide array of equipment, machinery, and appliances found in specific sectors.Additionally, the Vibration Absorbing Feet are designed to be easy to install, promoting hassle-free implementation across numerous applications. Whether affixed to heavy-duty machinery or lightweight handheld tools, the feet provide a reliable and efficient solution for professionals seeking to enhance stability and reduce vibrations in their work environment.Industry experts and early adopters who have had the opportunity to test the Vibration Absorbing Feet have been overwhelmingly positive in their feedback. Many have underscored the comfort and stability provided, highlighting the product's potential to significantly improve the overall user experience.With its Vibration Absorbing Feet, Company X reaffirms its commitment to driving innovation within the industry. By addressing the longstanding challenges of stability and vibration reduction, the company once again sets a benchmark for quality and performance, ensuring professionals can rely on efficient equipment while enhancing their safety and productivity.As the market demands heightened comfort, stability, and safety measures, Company X's commitment to innovation positions them as a frontrunner in the industry, constantly pushing boundaries and delivering cutting-edge solutions to meet the evolving needs of professionals across various sectors.About Company X:(Insert company introduction here)In conclusion, with the introduction of their Vibration Absorbing Feet, Company X has successfully developed a game-changing solution that enhances stability, reduces vibrations, and provides comfort across industries. Their commitment to innovation ensures that professionals can rely on their equipment while having a significantly improved user experience. The Vibration Absorbing Feet are set to revolutionize the field of stability and comfort, setting new industry standards and driving efficiency for professionals worldwide.

Durable and Versatile Corrugated Stainless Steel Sheets for Various Applications

Stainless Steel Corrugated Sheet: A Tough and Versatile Building MaterialStainless steel has long been known for its durability and versatility in a variety of applications. Whether it's used in kitchen appliances, medical equipment, or even the construction industry, stainless steel is a popular choice for its resistance to rust and corrosion, as well as its sleek and modern appearance.One particular application of stainless steel that has seen increasing popularity is the use of stainless steel corrugated sheets in the construction industry. These corrugated sheets offer a wide range of benefits, making them a popular choice for builders and architects alike.One company at the forefront of producing high-quality stainless steel corrugated sheets is {}. They have established themselves as a leading manufacturer of stainless steel products, including corrugated sheets, and are known for their commitment to producing high-quality, durable materials that meet the needs of their customers.The stainless steel corrugated sheets produced by {} are made from high-quality stainless steel, providing a strong and durable building material that is suitable for a wide range of applications. These sheets are designed to withstand harsh environmental conditions, making them particularly well-suited for outdoor use.One of the primary benefits of using stainless steel corrugated sheets is their resistance to corrosion. Unlike other building materials, such as wood or aluminum, stainless steel is not susceptible to rust or corrosion, making it an ideal choice for outdoor structures or buildings in coastal areas.In addition to their durability, stainless steel corrugated sheets are also known for their aesthetic appeal. The sleek and modern appearance of stainless steel makes it a popular choice for architects and designers looking to create a contemporary and stylish look for their buildings.Another key advantage of using stainless steel corrugated sheets is their versatility. They can be used in a wide range of applications, from roofing and siding to decorative panels and interior finishes. This versatility makes them a popular choice for builders and architects looking for a durable and attractive building material.Moreover, stainless steel corrugated sheets are also known for their ease of installation. The lightweight nature of stainless steel makes it easy to handle and transport, reducing the labor and time required for installation. This can result in cost savings for builders and contractors, making stainless steel corrugated sheets a cost-effective building material.{}'s commitment to quality and innovation sets them apart in the industry. With a focus on sustainability and environmental responsibility, they have developed a range of stainless steel corrugated sheets that are not only durable and aesthetically pleasing but also environmentally friendly.The company's dedication to quality is reflected in its state-of-the-art manufacturing facilities and rigorous quality control processes. This ensures that their stainless steel corrugated sheets meet the highest standards of quality and performance, providing customers with a reliable and long-lasting building material.In conclusion, stainless steel corrugated sheets offered by {} provide a durable, versatile, and aesthetically pleasing building material that is well-suited for a wide range of applications. With their resistance to corrosion, modern appearance, and ease of installation, stainless steel corrugated sheets are a popular choice for builders and architects looking for a high-quality and reliable building material. With {}'s commitment to quality and innovation, customers can trust in the durability and performance of their stainless steel corrugated sheets for their construction projects.

Benefits of Curved Corrugated Metal Panels for Your Building Projects

Title: Revolutionizing Construction: Curved Corrugated Metal Panels Redefine Structural DesignIntroduction:In an era where architecture and construction are constantly evolving, one innovative solution has emerged to redefine how structures are built. Curved corrugated metal panels have taken the industry by storm, offering a versatile and aesthetic option for building facades and roofing systems. [Company Name], a pioneering manufacturer in the field, has been at the forefront of the development and application of these groundbreaking panels.Paragraph 1:Curved corrugated metal panels have gained popularity rapidly due to their unique properties. These panels are made by forming metal sheets into a corrugated pattern, resulting in increased strength while reducing weight. The curvature of these panels allows builders and architects to create visually striking structures with enhanced durability.Paragraph 2:[Company Name], a leading manufacturer and provider of curved corrugated metal panels, has revolutionized the industry with their advanced designs and cutting-edge production techniques. By combining state-of-the-art technology with extensive research and development, the company has achieved unmatched quality and efficiency in their panel manufacturing process.Paragraph 3:One of the vital advantages of curved corrugated metal panels is their exceptional flexibility. Architects and designers can create unprecedented architectural forms by easily bending and shaping these panels to fit their desired structures. This flexibility is exemplified in projects that feature unique curves, arches, and other visually stunning designs. Such versatility has been harnessed in various applications such as stadiums, arenas, airports, commercial buildings, and residential projects.Paragraph 4:The aforementioned panels also boast remarkable durability and weather resistance. Manufactured using high-quality materials, they provide exceptional resistance to harsh weather conditions such as extreme temperatures, heavy rainfall, and windstorms. Combined with appropriate coatings, these panels also offer excellent protection against corrosion and wear, ensuring long-term performance and reduced maintenance costs.Paragraph 5:In addition to their structural and aesthetic qualities, curved corrugated metal panels have proven to be an environmentally friendly choice. These panels are often made from recyclable materials, reducing the carbon footprint associated with traditional construction materials. Furthermore, the lightweight nature of the panels allows for decreased energy consumption and transportation costs during installation.Paragraph 6:The growing demand for curved corrugated metal panels in the construction industry has led to an increased adoption rate among renowned architects and builders worldwide. With a track record of successful projects, [Company Name] has emerged as a trusted partner, providing reliable and customizable solutions backed by their technical expertise and commitment to customer satisfaction.Paragraph 7:To ensure the highest quality standards, [Company Name] employs a team of skilled engineers and technicians who closely monitor the manufacturing process at every stage. The company also offers design and engineering support, helping clients visualize their concepts and implement them effectively.Paragraph 8:As the construction industry continues to evolve, curved corrugated metal panels are set to play an increasingly significant role in shaping modern architecture. With their capacity to enhance aesthetic appeal, durability, and sustainability, these panels provide a sustainable and practical solution for meeting the ever-changing needs of the industry.Conclusion:Curved corrugated metal panels have revolutionized the construction industry, offering architects and builders an unparalleled combination of flexibility, aesthetic appeal, and durability. [Company Name] has played a pivotal role in advancing this technology, providing premium-quality solutions that have become synonymous with innovation and excellence. With an ever-growing demand for such panels, the future of construction is indeed curved.

Affordable Spiral Conveyor: Evaluating the Cost Factors

Title: The Future of Material Handling: Cutting-Edge Spiral Conveyors Set to Revolutionize the IndustryIntroduction:In an increasingly globalized world, efficient material handling solutions are vital for businesses to streamline their operations and stay ahead of the competition. Recognizing this necessity, several companies have pioneered innovative technologies to optimize logistics and enhance supply chain efficiency. One such revolutionary development is the advent of spiral conveyors, which are poised to revolutionize the material handling sector. With their cost-effective and space-saving design, these cutting-edge conveyors offer businesses unparalleled advantages. In this article, we will explore the world of spiral conveyors, their benefits, and how they are reshaping the landscape of the industry.1. Understanding Spiral Conveyors: Spiral conveyors are a vertical transportation system that efficiently and continuously moves goods between different floor levels. Unlike traditional conveyors, spiral conveyors utilize a unique spiral-shaped belt, enabling them to accomplish greater elevation changes within a confined footprint. This makes them ideal for warehouses and manufacturing facilities with limited floor space. The integration of advanced technology and engineering principles ensures a smooth and seamless transportation process, minimizing the risk of damage to goods.2. Key Advantages of Spiral Conveyors: 2.1 Space Optimization:Spiral conveyors offer a significant advantage over traditional conveyors by efficiently utilizing vertical space. With their compact and spiral design, they occupy less floor area while maximizing storage capacity. By eliminating the need for multiple conveyors or elevators, businesses can optimize their layouts, resulting in a more organized and productive workflow.2.2 Enhanced Efficiency:Spiral conveyors offer continuous material flow, minimizing bottlenecks and reducing manual labor. With a higher throughput capacity, they enable faster and more efficient movement of goods, resulting in reduced production times. Their seamless integration with other automated systems, such as sorting and packaging machinery, further enhances operational efficiency and overall productivity.2.3 Flexibility and Versatility:These state-of-the-art conveyors are engineered to handle a wide range of products, from small and delicate items to heavy and bulky goods. Customizable options, such as variable speed controls and adjustable lane widths, ensure compatibility with diverse industry needs. The adaptability of spiral conveyors makes them a viable solution for various sectors, including manufacturing, e-commerce, pharmaceuticals, and food processing.2.4 Cost-effectiveness:While the initial investment in spiral conveyors may seem higher than traditional conveyors, the long-term cost savings outweigh the initial expenditure. The space-saving design reduces the need for additional infrastructure, resulting in lower construction and maintenance costs. Additionally, the efficient flow of materials minimizes the risk of product damage, reducing operational expenses and increasing overall profitability.3. Industry Leader's Contribution: {}is a renowned innovator in the field of material handling solutions, including the groundbreaking spiral conveyor technology. With years of experience and expertise, they have established themselves as a trusted partner for businesses seeking to optimize their supply chains. By seamlessly integrating their Spiral Conveyor system with cutting-edge software and technologies, {} has transformed material handling processes across industries.4. Future Prospects and Conclusion:The rapid technological advancements in the material handling industry indicate a promising future for spiral conveyors. As businesses worldwide strive for enhanced efficiency, lowered costs, and maximized productivity, the demand for innovative solutions will continue to surge. Spiral conveyors, with their space-saving design, flexibility, and cost-effectiveness, are well-positioned to dominate this evolving market. As companies embrace the benefits of these revolutionary conveyors, they have the potential to reshape the material handling sector and pave the way for even greater advancements in logistics and supply chain management.

Discover the Advantages of Slat Top Chain Belts for Efficient Material Handling

Slat Top Chain Belt: Revolutionizing the Manufacturing IndustryThe manufacturing industry has seen a significant transformation in recent years, with technological advancements making it easier for manufacturers to improve their processes and maximize their output. One of the most groundbreaking innovations in the industry is the Slat Top Chain Belt.Offering a myriad of benefits, including increased efficiency, productivity, and versatility, the Slat Top Chain Belt has revolutionized the way manufacturers operate. In this article, we will explore the advantages of the Slat Top Chain Belt and how it can help businesses improve their bottom line.What is a Slat Top Chain Belt?A Slat Top Chain Belt is a type of conveyor belt that is made up of a series of plates, connected together with hinges, and supported by a chain. The plate and hinge design of the belt provides a flat surface that can be used to transport a variety of products, ranging from small components to large, heavy items.Slat Top Chain Belts are typically used in manufacturing and material handling applications, where they are used to move products through a production line or warehouse. They are popular in industries such as food and beverage, automotive, pharmaceuticals, and packaging, among others.Benefits of a Slat Top Chain BeltIncreased EfficiencyOne of the most significant advantages of a Slat Top Chain Belt is that it increases efficiency in manufacturing processes. With a flat, stable surface, the belt ensures products are transported smoothly through the production line, without any disruption or damage. The belt's ability to handle a wide range of products, from small components to large, bulky items, also makes it perfect for businesses that have a diverse range of products to manufacture.Improved ProductivitySlat Top Chain Belts are designed to move products quickly and efficiently through the production line, which helps to improve productivity. By automating the process of moving products, manufacturers can free up human resources to focus on other tasks, such as quality control or research and development. The use of Slat Top Chain Belts also ensures a consistent, reliable flow of products, which helps to minimize downtime and increase throughput.VersatilitySlat Top Chain Belts are incredibly versatile and can be used in a wide range of applications, making them an excellent investment for businesses that have a diverse range of products to manufacture. They can be used to transport products in straight lines, curves, or even vertically, depending on the needs of the production line. The belts can also be customized to meet specific requirements, making them suitable for a broad range of manufacturing applications.DurabilitySlat Top Chain Belts are engineered to withstand the rigors of industrial use, which means they are highly durable and built to last. They are typically made from high-quality materials, such as stainless steel or heavy-duty plastics, that can withstand exposure to harsh chemicals, extreme temperatures, and heavy loads. The inherent durability of Slat Top Chain Belts makes them a fantastic investment for manufacturers looking for a long-term, low-maintenance solution.Reduced Labor CostsSlat Top Chain Belts can help to reduce labor costs by automating the process of moving products through the production line. With the belt doing the heavy lifting, human resources can be freed up to tackle other tasks, which can help to reduce labor costs and improve overall productivity.In conclusion, the Slat Top Chain Belt is a revolutionary innovation that has transformed the manufacturing industry. Offering a range of benefits, including increased efficiency, productivity, versatility, durability, and reduced labor costs, the belt has become an essential tool for businesses looking to optimize their production lines. With the market for Slat Top Chain Belts set to grow in the coming years, manufacturers must take advantage of this technology and stay ahead of the competition.

Discover the Importance of 2 Square Tubing Caps and Their Applications

Title: Innovative Solution for Durable Protection of Square TubingIntroduction:(Company Name) is proud to introduce a revolutionary product that provides enhanced durability and protection to square tubing in various industries. Designed to deliver top-quality performance, the 2 Square Tubing Caps by (Company Name) effectively safeguard against damage, corrosion, and wear and tear, prolonging the longevity of square tubing.Innovation and Quality:(Company Name) has been a leading provider of high-quality industrial solutions for over a decade. With a focus on innovation, our team of experts has developed the 2 Square Tubing Caps to address the common challenges faced by industries relying on square tubing. Built with precision and utilizing only premium materials, these caps are engineered to meet the highest quality standards, ensuring maximum performance and protection.Superior Protection:Square tubing is commonly used in a wide range of applications, including construction, manufacturing, and transportation. However, exposure to external elements and heavy loads often leads to damage, dings, and corrosion, ultimately reducing the tubing's lifespan. The 2 Square Tubing Caps by (Company Name) provide an easy-to-install, durable solution to mitigate these issues and maintain the structural integrity of the tubing.The caps are designed to fit securely over the square tubing, forming a protective barrier against impact, moisture, dirt, and debris. This effective sealing mechanism prevents rust and corrosion, safeguarding the tubing and allowing it to withstand harsh environmental conditions. Industries utilizing square tubing can now benefit from increased reliability and reduced maintenance costs, thanks to this innovative solution.Versatility in Application:The versatility of the 2 Square Tubing Caps makes them suitable for various industries and applications. Whether utilized in construction projects, industrial machinery, outdoor structures, or transportation equipment, these caps provide consistent protection against external forces and potential damage. Their universal design ensures compatibility with various sizes of square tubing, offering a hassle-free solution for businesses across different sectors.Enhanced Safety and Lower Maintenance Costs:By effectively safeguarding square tubing, the 2 Square Tubing Caps offer tangible benefits in terms of safety and reduced maintenance expenses. With these caps in place, the risk of accidents caused by weakened or damaged tubing is significantly reduced, ensuring a safer working environment for employees. Moreover, the extended lifespan of the tubing eliminates the need for frequent replacements, resulting in cost savings for businesses.Environmentally Friendly Solution:In addition to their superior protective capabilities, the 2 Square Tubing Caps are also environmentally friendly. By preventing wear and corrosion, these caps contribute to reducing waste generated from discarded or damaged square tubing. The longevity of tubing, facilitated by these caps, promotes sustainable practices and reduces the carbon footprint of businesses.Conclusion:Investing in the 2 Square Tubing Caps by (Company Name) is a wise choice for businesses seeking the highest level of protection and durability for square tubing. With their innovative design, compatibility with various sizes, and superior performance, these caps offer a cost-effective solution to prolong the lifespan of tubing while ensuring safety and reducing maintenance expenses. (Company Name) once again leads the industry with an advanced product that sets new standards in the protection of square tubing.

Discover the Convenience and Durability of Plastic Caps for Box Sections

Plastic Caps for Box Section: Ensuring Safe and Secure Packaging SolutionsIn today's fast-paced world, packaging plays a crucial role in preserving the quality and integrity of products during transportation and storage. As various industries continue to evolve, so do the packaging solutions required to meet their specific needs. One such solution that has gained significant attention is the use of plastic caps for box sections.Plastic caps for box sections, often made of high-density polyethylene (HDPE), are designed to cover and protect the ends of box sections. These caps create a secure barrier, preventing dust, moisture, and other contaminants from entering and potentially damaging the contents. They ensure that the shipped products remain intact and reach their destination in pristine condition.As the demand for efficient and sustainable packaging solutions rises, more companies are turning to plastic caps for box sections due to their numerous benefits. Let's explore the advantages of using these caps and how they contribute to a safer and more secure packaging process.Protection: Box sections are widely used in industries such as construction, automotive, and furniture manufacturing, where the components are often prone to damage without proper care. Plastic caps act as a protective shield, safeguarding the exposed ends from impact, scratches, and abrasions. This helps in minimizing potential losses and reducing the need for costly replacements.Secure sealing: The snug fit provided by plastic caps ensures that the box sections are securely closed, preventing any accidental openings during handling or transport. This feature is especially important when shipping delicate or valuable products, as it minimizes the risk of theft or damage.Durability: Plastic caps made from HDPE are renowned for their durability and resistance to environmental factors such as UV rays, extreme temperatures, and moisture. This robustness prolongs the lifespan of the caps, allowing for multiple uses and reducing the overall packaging costs.Versatility: Plastic caps for box sections are available in various shapes and sizes to accommodate different dimensions and applications. They can be easily customized to fit specific box section sizes, offering a flexible solution for diverse packaging requirements.Efficiency: By using plastic caps, companies can streamline their packaging process. These caps are lightweight and easy to handle, allowing for swift sealing and unsealing of box sections. Additionally, their universal design enables quick identification and retrieval of products, saving valuable time in warehouses or storage facilities.Sustainability: As the world becomes increasingly conscious of environmental issues, sustainable packaging solutions have become paramount. Plastic caps for box sections, made from recyclable materials, align with the principles of sustainable packaging. Additionally, their durability reduces the need for single-use alternatives, contributing to waste reduction.Leading the Industry: One company at the forefront of providing top-quality plastic caps for box sections is {}. With decades of experience in the packaging industry, they have established themselves as a trusted supplier of innovative solutions. Their range of plastic caps caters to a broad spectrum of industries, ensuring the safe handling and transportation of their products.Located in {}, {} consistently delivers high-quality products backed by a commitment to customer satisfaction. Working closely with their clients, they understand the unique packaging needs of different industries and provide customized solutions designed to meet specific requirements.The company's dedication to quality is evident in their manufacturing process, where they utilize state-of-the-art technology to ensure precise measurements and superior product performance. Their strict quality control measures guarantee that each plastic cap adheres to the highest standards of durability and protection.Furthermore, {} emphasizes sustainability by using eco-friendly materials and minimizing waste in their operations. They strive to contribute to a greener future by encouraging the use of recyclable packaging materials.In conclusion, plastic caps for box sections have emerged as a reliable solution for ensuring safe and secure packaging. With their ability to protect, seal, and provide durability, these caps are the go-to choice for industries seeking efficient and sustainable packaging solutions. With companies like {} leading the way, businesses can rest assured knowing their products are in good hands.

Innovative Container Making Solutions for Your Packaging Needs

Container Making Company Announces Expansion PlansContainer making is a crucial aspect of the packaging industry, and one company is taking significant steps to expand its operations in order to meet the growing demand for its products. With a strong focus on quality and innovation, [Company] is making waves in the industry, and its expansion plans are set to solidify its position as a leader in the container making business.Established in [year], [Company] has quickly established itself as a trusted name in the packaging industry. With a commitment to producing high-quality containers and a dedication to meeting the needs of its customers, the company has experienced rapid growth in recent years. Its state-of-the-art manufacturing facilities and skilled team of professionals have allowed [Company] to offer a wide range of container options, catering to the diverse needs of various industries.The company's expansion plans come at a time when the demand for containers is on the rise. As more businesses recognize the importance of packaging in brand identity and product protection, the need for high-quality, reliable containers has never been greater. [Company] is well-positioned to capitalize on this growing demand, and its expansion plans will allow it to further solidify its presence in the market.In order to accommodate its growth and meet the increasing demand for its products, [Company] has announced plans to build a new, state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and machinery, allowing the company to increase its production capacity and streamline its operations. By doing so, [Company] aims to not only meet the current demand for its containers but also to prepare for future growth in the industry.In addition to the new manufacturing facility, [Company] also plans to expand its product line to offer even more options to its customers. With a focus on innovation and customer satisfaction, the company is committed to developing new and improved container solutions that meet the evolving needs of its clients. By expanding its product line, [Company] aims to become a one-stop shop for all container needs, further solidifying its position as a market leader.The expansion plans have generated excitement within the company and the industry as a whole. [Company] is known for its commitment to quality, innovation, and customer satisfaction, and the company's expansion plans are a testament to its dedication to these values. The new manufacturing facility and expanded product line will not only allow the company to better serve its existing customers but also attract new clients who are seeking high-quality container solutions.As the company prepares for this significant expansion, it remains committed to its core values and mission. [Company] is dedicated to producing containers that meet the highest standards of quality and performance, and its expansion plans are a reflection of this dedication. By investing in new technology, machinery, and product development, the company is positioning itself for long-term success in the container making business.Overall, the expansion plans announced by [Company] are set to further solidify the company's position as a leader in the container making industry. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for its products and continue to thrive in the industry. As the new manufacturing facility takes shape and the product line expands, [Company] is poised to make an even greater impact on the container making business.