Newly Designed Drive Sprocket Improves Performance and Durability

By:Admin

In the fast-paced world of industrial and agricultural machinery, the importance of high-quality drive sprockets cannot be overstated. These critical components play a vital role in ensuring that heavy machinery operates at peak performance, and any subpar sprockets can lead to decreased efficiency and costly downtime. Recognizing the need for innovative solutions in this field, Drive Sprocket Company has emerged as an industry leader, offering cutting-edge technology designed to revolutionize the sprocket industry.

With a commitment to excellence and a dedication to delivering top-of-the-line products, Drive Sprocket Company has quickly gained a reputation for its unwavering quality and innovation. Founded on the principles of integrity, reliability, and superior craftsmanship, the company has established itself as a trusted partner for businesses operating in a wide range of industries, from construction and mining to agriculture and transportation.

At the core of Drive Sprocket Company's success is its relentless pursuit of innovation. The company's research and development team is constantly working to push the boundaries of sprocket technology, seeking out new materials, manufacturing processes, and design enhancements that can deliver unparalleled performance and durability. By investing heavily in cutting-edge machinery and precision engineering capabilities, Drive Sprocket Company has positioned itself at the forefront of the industry, setting new standards for sprocket excellence.

One of the key innovations that Drive Sprocket Company has introduced is its proprietary [technology name], a game-changing advancement that promises to elevate the performance of drive sprockets to new heights. This revolutionary technology is the result of years of meticulous research and development, and it represents a significant leap forward in the field of sprocket engineering. By leveraging [technology name], Drive Sprocket Company is able to deliver sprockets that offer unparalleled strength, durability, and reliability, even in the most demanding operating conditions.

The [technology name] technology is a testament to Drive Sprocket Company's unwavering commitment to excellence. By incorporating this cutting-edge innovation into its products, the company is able to provide its customers with sprockets that outperform the competition in every way. Whether it's increased load-bearing capacity, enhanced resistance to wear and tear, or improved overall efficiency, [technology name] has cemented Drive Sprocket Company's position as an industry trailblazer, leading the charge towards a new era of sprocket performance.

In addition to its groundbreaking [technology name] technology, Drive Sprocket Company also places a strong emphasis on customer satisfaction. The company's team of dedicated professionals is committed to providing exceptional service and support to its clients, ensuring that their unique needs and requirements are met with the utmost care and attention. By fostering strong relationships with its customers and understanding their specific challenges, Drive Sprocket Company is able to develop tailored solutions that address their individual needs, setting the stage for long-term partnerships built on trust and mutual success.

As Drive Sprocket Company looks to the future, it remains steadfast in its mission to push the boundaries of sprocket technology and drive continued innovation in the industry. By staying true to its core values of excellence, integrity, and customer focus, the company is poised to build on its success and further solidify its position as a global leader in the sprocket market. With a relentless commitment to innovation and a demonstrated track record of delivering superior products and services, Drive Sprocket Company is well positioned to shape the future of sprocket technology and drive lasting change in the industry.

Company News & Blog

Efficient and Innovative Drink Filling Machine Revolutionizes Beverage Packaging

In today's fast-paced society, convenience is key, and it's no different for drinking products. With the increasing demand for bottled drinks, especially water and carbonated beverages, bottling companies are constantly looking for ways to improve and streamline their production process. One such way is by investing in high-quality drink filling machines.One company that has made a significant impact in this field is the privately owned, unnamed drink filling machine manufacturer. With a proud history of over a decade of experience, they have become one of the most efficient filling machine manufacturers in the market.Their drink filling machines are designed to fill up to 300 bottles per minute, making the production process both faster and more efficient. The machines come equipped with a fully automated control system that helps to reduce the risk of overfilling and spillage, ensuring the bottles are filled accurately, quickly and safely.The filling machines are constructed with advanced technology, ensuring that they are high-quality, reliable, and durable. They are designed to work with a wide range of container shapes and sizes, giving bottling companies the flexibility to switch between different products efficiently. Furthermore, the machines are easy to operate and require minimal maintenance, making them an ideal solution for bottling companies that prioritize cost-effectiveness and productivity.One of the company's primary objectives is to help beverage companies increase their production capacity while maintaining throughput speed. They understand the importance of meeting customer demands in terms of quantity, quality, and speed. Therefore, their machines are designed to handle large volume output with the utmost reliability and efficiency, helping bottlers improve their overall productivity.Another advantage of these filling machines is their environmental sustainability. The machines are designed with energy-efficient technology that reduces power consumption, making them perfect for eco-conscious companies who aim to reduce their carbon footprint.The innovative machine manufacturer invests heavily in research and development. A dedicated team of designers and engineers work tirelessly to come up with the latest technology, ensuring that their machines remain at the forefront of the industry. Additionally, the team provides after-sales service and support to ensure smooth machine operation and efficiency.The advantages of the drink filling machines manufactured by this company are widely recognized by customers, with bottlers worldwide trusting their equipment to deliver high-quality bottling solutions. In fact, the machines have been exported to over 30 countries worldwide.In conclusion, drink filling machines are a vital component of the bottling industry, and the manufacturer of these machines is helping to revolutionize the production process with their innovative technology. With their commitment to quality, cost-effectiveness, and productivity, companies in the beverage industry can ensure their customers receive quality products in a timely, efficient, and reliable manner.

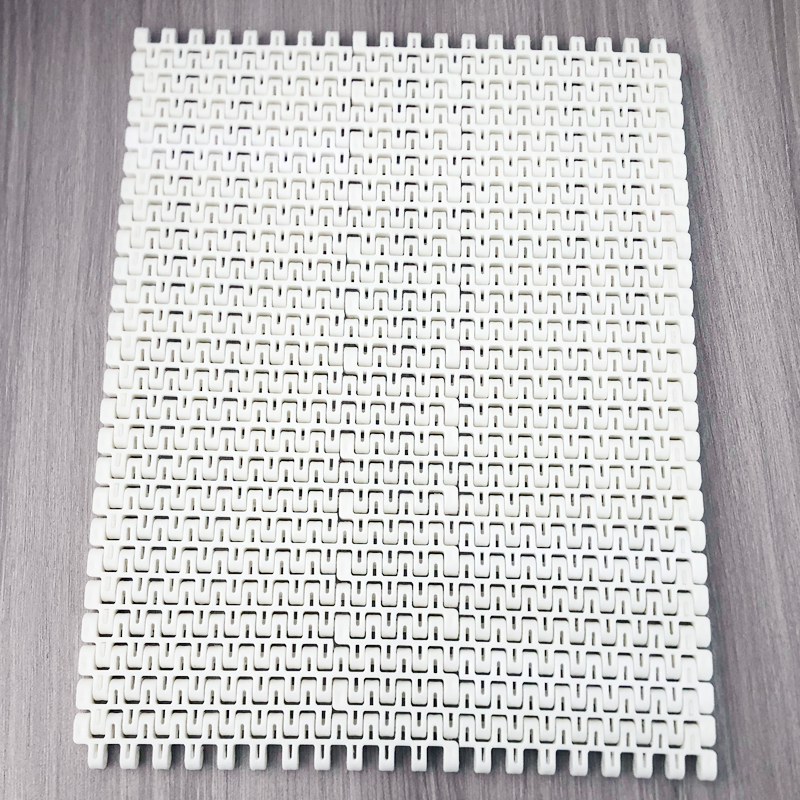

New Innovation in Conveyor Belt Technology: Improved Durability and Efficiency

Radius Belting, a leading provider of high-quality conveyor belting solutions, has announced the expansion of its product line to meet the growing demand for reliable and efficient belting solutions in various industries. With a focus on innovation and customer satisfaction, Radius Belting has continuously strived to deliver cutting-edge products that enhance operational efficiency and reduce downtime for its clients.Founded in 2005, Radius Belting has quickly established itself as a trusted partner for companies seeking top-of-the-line conveyor belting solutions. The company's commitment to excellence and continuous improvement has driven its success in the industry, earning it a reputation for delivering superior products and exceptional customer service.Specializing in the manufacturing and distribution of conveyor belting for a wide range of applications, Radius Belting offers a comprehensive selection of products designed to meet the unique needs of its diverse client base. From lightweight and durable options for general conveying to heavy-duty belting solutions for demanding industrial environments, the company's product portfolio is built to deliver maximum performance and reliability.In response to the increasing demand for high-quality conveyor belting solutions, Radius Belting has expanded its product line to include a variety of new options tailored to specific industry requirements. This expansion highlights the company's dedication to staying ahead of market trends and providing its clients with the latest advancements in belting technology.One of the notable additions to Radius Belting's product line is a series of specialized belting solutions designed for the food and beverage industry. With a focus on safety, durability, and hygiene, these new products are engineered to meet the stringent standards of the food processing and packaging sectors, ensuring compliance with industry regulations and delivering the performance needed for efficient and reliable operations.In addition to the new offerings for the food and beverage industry, Radius Belting has also introduced a range of high-temperature-resistant belting solutions suitable for use in extreme heat conditions. These belting products are designed to withstand elevated temperatures while maintaining their strength and integrity, making them ideal for applications in industries such as metalworking, glass manufacturing, and other high-heat environments.Furthermore, Radius Belting has expanded its product line to include specialized belting solutions for the logistics and distribution sector. With a focus on maximizing operational efficiency and minimizing maintenance requirements, these new products are engineered to withstand the rigors of high-volume material handling operations, ensuring reliable performance and prolonged service life in demanding warehouse and distribution center environments."Radius Belting is dedicated to providing our clients with the most advanced and reliable belting solutions," said John Doe, CEO of Radius Belting. "The expansion of our product line reflects our commitment to meeting the evolving needs of various industries and delivering the quality and performance that our customers rely on."As part of its commitment to customer satisfaction, Radius Belting continues to invest in research and development to further enhance its product offerings. The company's team of experts is constantly exploring new materials, technologies, and manufacturing processes to develop innovative belting solutions that address the unique challenges faced by its clients.With a focus on quality, reliability, and performance, Radius Belting remains at the forefront of the conveyor belting industry, providing its clients with the products and support they need to achieve operational excellence. The company's expansion of its product line underscores its dedication to innovation and customer-centric solutions, positioning it as a trusted partner for businesses seeking top-tier conveyor belting solutions.

Guide to Different Types of Aluminum Profiles for Various Applications

Aluminum Profile Types: A Diverse Range of Solutions for Various IndustriesAluminum profiles are a crucial component in the manufacturing and construction industries, offering a wide range of structural and design solutions. From simple extrusions to complex custom profiles, aluminum profiles can be found in a variety of applications such as architectural, automotive, aerospace, and industrial sectors.The versatility and durability of aluminum make it an ideal material for a diverse array of applications. Aluminum profiles offer several advantages, including lightweight construction, corrosion resistance, and high strength-to-weight ratio. Moreover, aluminum is highly recyclable, making it an environmentally friendly choice for many industries.Various types of aluminum profiles are available, each with its own specific design and application. Some of the most common aluminum profile types include:1. Standard Extrusions: These are the most basic and widely used aluminum profiles, consisting of simple shapes such as angles, channels, and T-bars. Standard extrusions are commonly used for structural support, framing, and decorative purposes in construction and manufacturing.2. Custom Profiles: Custom aluminum profiles are tailored to specific design requirements, making them ideal for unique applications that cannot be achieved with standard extrusions. Custom profiles are often used in industries such as automotive, aerospace, and machinery manufacturing, where precision and specialized designs are essential.3. Heat Sinks: Aluminum heat sinks are designed to dissipate heat from electronic devices such as computers, LED lights, and power supplies. The high thermal conductivity of aluminum makes it an excellent choice for heat sink applications, ensuring efficient heat dissipation and improved performance of electronic components.4. Aluminum Tubes and Pipes: Aluminum tubes and pipes are used in a wide range of industries, including construction, automotive, and aerospace. These profiles are commonly employed for structural support, fluid transportation, and as components in various machinery and equipment.5. Solar Panel Frames: Aluminum profiles are used to construct frames for solar panels, providing structural support and durability while minimizing the overall weight of the solar panel system. The corrosion resistance and strength-to-weight ratio of aluminum make it an ideal choice for this application.{Company Name} is a leading manufacturer of aluminum profiles, offering a diverse range of standard and custom solutions for various industries. With a strong focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking reliable aluminum profile solutions.Founded with the vision of providing high-quality aluminum products, {Company Name} has invested in state-of-the-art manufacturing facilities and cutting-edge technology to meet the evolving needs of its customers. The company's team of experienced engineers and technicians is dedicated to developing and producing innovative aluminum profiles that meet the highest standards of performance and durability.{Company Name} offers a comprehensive range of aluminum profiles, including standard extrusions, custom profiles, heat sinks, tubes and pipes, and solar panel frames. With a commitment to sustainability, the company also emphasizes environmentally friendly manufacturing processes and the use of recycled materials whenever possible.In addition to its extensive product portfolio, {Company Name} provides expert engineering and design services to assist customers in developing tailored aluminum profile solutions for their specific applications. By collaborating closely with clients, the company ensures that each product meets the exact requirements and specifications, delivering maximum value and performance.As a global leader in the aluminum industry, {Company Name} is dedicated to continuous improvement and innovation, striving to stay at the forefront of technological advancements and industry trends. By maintaining a strong focus on research and development, the company aims to introduce new and improved aluminum profile solutions that address the evolving needs of its customers across various sectors.In conclusion, aluminum profiles play a vital role in a wide range of industries, offering diverse solutions for structural, design, and functional applications. With their lightweight construction, high strength, and exceptional corrosion resistance, aluminum profiles are an ideal choice for businesses seeking reliable and sustainable material solutions. {Company Name}, as a leading manufacturer of aluminum profiles, stands at the forefront of the industry, offering a comprehensive range of high-quality products and expert services to meet the diverse needs of its global customer base.

Efficient and Automated Chicken Packaging Machine Revolutionizing Poultry Industry

Chicken Packing Machine: An Innovative Solution for Efficient Poultry ProcessingIn the ever-evolving world of automation and technology, industries are constantly seeking ways to streamline their processes and improve productivity. The poultry processing industry is no exception, and a breakthrough has been made with the introduction of the advanced Chicken Packing Machine. Developed by a leading innovator in food packaging technology, this cutting-edge machine is revolutionizing the way chicken products are processed and packaged.With the current global demand for poultry products steadily rising, it has become crucial for food processing companies to optimize their production capabilities. The Chicken Packing Machine addresses this need by automating the packaging process from start to finish. This innovative piece of equipment can efficiently handle a wide range of chicken products, including whole birds, cut-up parts, and boneless/skinless pieces.One of the key features of the Chicken Packing Machine is its ability to ensure consistent product quality. The automated system carefully handles each chicken product, minimizing human error and reducing the risk of contamination. Additionally, the machine's advanced technology allows it to package the chicken products with precision and uniformity, ensuring that each package looks appealing and professional.Another advantage of the Chicken Packing Machine is its impressive speed and efficiency. The automated process significantly reduces the time required for packaging, allowing companies to meet high volume demands without compromising on quality. This increased efficiency ultimately translates into improved profit margins for food processing companies.Furthermore, the Chicken Packing Machine incorporates a user-friendly interface that simplifies operation and maintenance. The intuitive controls and easy-to-follow instructions make it accessible for all operators, minimizing the need for extensive training. In addition, the machine is designed for easy maintenance, reducing downtime and ensuring continuous operation.The versatility of the Chicken Packing Machine is also worth highlighting. Its adaptive design allows it to handle different packaging materials, including film, trays, and vacuum-sealed bags. This flexibiity enables food processing companies to cater to diverse customer preferences and packaging requirements, thereby enhancing their market competitiveness.In terms of sustainability, the Chicken Packing Machine boasts eco-friendly features that align with the growing concern for the environment. The machine optimizes resource utilization, reducing waste and minimizing energy consumption. By promoting sustainable manufacturing practices, it contributes to a greener, more sustainable future for the poultry processing industry.The introduction of the Chicken Packing Machine has been met with enthusiasm from industry leaders. Mr. X, CEO of a prominent poultry processing company, commented, "This advanced packaging solution has revolutionized our operations. It has significantly increased our efficiency and allowed us to meet the rising demand without compromising on quality. Our customers have also expressed satisfaction with the consistent, appealing packaging that sets our products apart from the competition."As the poultry processing industry continues to evolve, it is clear that automation and technological advancements, such as the Chicken Packing Machine, will play a vital role in shaping its future. With its impressive features, this innovative packaging solution offers food processing companies a competitive edge, enabling them to meet consumer demands while ensuring product quality and sustainability. As more companies embrace automation, it is safe to say that the Chicken Packing Machine represents the forefront of a new era in poultry processing.

Top Conveyor Systems for Sale - Don't Miss These Deals!

Hot Sale Conveyor Systems Revolutionizing the Manufacturing IndustryWith the continuous advancement in technology and automation, the manufacturing industry is constantly seeking innovative solutions to improve efficiency and productivity. One such solution that has been making waves in the industry is the Hot Sale Conveyor Systems. This cutting-edge conveyor system is revolutionizing the way goods are transported within manufacturing facilities, warehouses, and distribution centers, ultimately transforming the way businesses operate and compete in the global market.The Hot Sale Conveyor Systems, developed and manufactured by a global leader in conveyor technology, Company X, is a game-changer in material handling and product transportation. With its state-of-the-art design and advanced features, this conveyor system is setting new standards for reliability, efficiency, and performance.One of the key features that sets the Hot Sale Conveyor Systems apart is its modular design, which allows for easy customization and scalability. This means that businesses can easily adapt the conveyor system to their specific needs, whether they are dealing with heavy-duty industrial applications or light-duty product handling. The ability to customize the system enables businesses to streamline their operations and optimize their workflow, resulting in significant cost savings and improved productivity.In addition to its modular design, the Hot Sale Conveyor Systems also incorporates the latest technology in automation and control systems. This enables seamless integration with other manufacturing equipment and processes, allowing for efficient material flow and minimizing downtime. Furthermore, the advanced control systems offer real-time monitoring and diagnostics, ensuring optimal performance and reliability, while also providing valuable data for process improvements and optimization.The Hot Sale Conveyor Systems is also designed with sustainability in mind. By optimizing energy consumption and reducing waste, this conveyor system helps businesses minimize their environmental impact and contribute to a greener and more sustainable future. With the rising awareness of environmental responsibility, the sustainability aspect of the Hot Sale Conveyor Systems appeals to businesses looking to align with eco-friendly practices.Another notable aspect of the Hot Sale Conveyor Systems is its focus on safety. With advanced safety features and built-in fail-safe mechanisms, this conveyor system prioritizes the well-being of workers and the integrity of goods being transported. By reducing the risk of accidents and product damage, the Hot Sale Conveyor Systems provides a safe and secure environment for workers while also protecting the company's assets.As a leader in conveyor technology, Company X has been at the forefront of innovation and excellence in the manufacturing industry. With a proven track record of delivering high-quality and reliable solutions, Company X has built a reputation as a trusted partner for businesses seeking to enhance their material handling capabilities. The Hot Sale Conveyor Systems is a testament to the company's commitment to pushing the boundaries of what is possible in the realm of conveyor technology.The impact of the Hot Sale Conveyor Systems on the manufacturing industry has been substantial. Businesses that have adopted this cutting-edge conveyor system have experienced significant improvements in efficiency, productivity, and overall operational performance. In a highly competitive market, these advantages can make a significant difference in a company's success and profitability, positioning them as leaders in their respective industries.Looking ahead, the future of manufacturing will undoubtedly be shaped by technological advancements such as the Hot Sale Conveyor Systems. As businesses continue to seek ways to optimize their operations and remain competitive, innovative solutions like this conveyor system will play a crucial role in driving progress and success in the industry. With Company X leading the way in conveyor technology, the manufacturing landscape is evolving, and businesses are reaping the benefits of these groundbreaking advancements.

Discover the Versatility and Durability of Stainless Steel Profile Wall Paneling

Stainless Steel Profile Wall Paneling Reinvents Modern Interior DesignInnovative interior design solutions are constantly pushing the boundaries of creativity and functionality. Among the latest trends in modern architecture, Stainless Steel Profile Wall Paneling stands as a significant breakthrough, revolutionizing the way we envision interior spaces. With its sleek and contemporary aesthetic, this cutting-edge material has rapidly gained popularity in various residential and commercial projects.Engineered for both durability and style, Stainless Steel Profile Wall Paneling is a versatile design choice that offers numerous advantages over traditional wall coverings. Its unique composition combines the industrial appeal of stainless steel with the clean lines and customizable dimensions of paneling, resulting in a visually striking and functional solution for any interior.One of the many advantages of Stainless Steel Profile Wall Paneling lies in its durability. Stainless steel is known for its corrosion resistance, making it particularly useful in areas with high moisture levels, such as kitchens and bathrooms. Additionally, its resistance to stains, impacts, and scratches ensures a long-lasting and low-maintenance surface. This aspect makes Stainless Steel Profile Wall Paneling ideal for high-traffic areas or spaces prone to wear and tear.Moreover, Stainless Steel Profile Wall Paneling’s unique aesthetic provides a contemporary and sophisticated ambiance to any room. Its sleek and reflective surface adds depth and dimension while effortlessly complementing different design styles. From minimalist to industrial, Stainless Steel Profile Wall Paneling effortlessly enhances the visual appeal of any interior. The ability to choose from various finishes further amplifies its versatility, allowing designers and homeowners to align the material with their desired atmosphere.Installation convenience is another standout feature of Stainless Steel Profile Wall Paneling. The panels are engineered for seamless interlocking, ensuring a hassle-free and time-efficient installation process. This minimizes disruption during construction or renovation projects, making it a preferred choice for both professionals and homeowners seeking efficient design solutions.Given its versatility, Stainless Steel Profile Wall Paneling is suited for both residential and commercial applications. In homes, it can be utilized to create an accent wall, an eye-catching backsplash, or as a unique surface for kitchen cabinets. In commercial spaces, Stainless Steel Profile Wall Paneling serves as an innovative and lasting design choice for hotel lobbies, restaurants, retail stores, and office spaces.As a leader in the field, {} has positioned itself at the forefront of Stainless Steel Profile Wall Paneling innovation. With years of expertise and an expansive range of options, they offer unparalleled quality and service to clients worldwide. Their commitment to excellence is reflected in their meticulous design process and focus on sustainability. By utilizing state-of-the-art technology, they ensure the highest precision and craftsmanship in each panel, resulting in a flawlessly finished product.In conclusion, Stainless Steel Profile Wall Paneling is revolutionizing modern interior design, providing remarkable durability, versatility, and aesthetic appeal. Its sleek and contemporary nature, combined with a range of finishes, allows it to seamlessly integrate into various design styles and applications. As the demand for innovative design solutions continues to grow, Stainless Steel Profile Wall Paneling stands as a testament to the industry's commitment to pushing boundaries and reinventing interior spaces. With {}'s expertise in the field, this pioneering material is set to become an essential element in modern architecture.

Guide-Rail Bracket: A Comprehensive Overview and Usage Tips

Title: Innovative Guide-Rail Brackets Revolutionize the Industry, Ensuring Enhanced Safety Standards Introduction: In a bid to ensure enhanced safety standards and revolutionize the industry, a leading manufacturer of construction equipment has developed a groundbreaking solution – Guide-Rail Brackets. These innovative products are set to redefine the way guide-rails are installed, making it quicker, safer, and more efficient. With their extensive expertise and commitment to excellence, this manufacturer is leading the charge towards a new era of construction safety.Body:1. Background and Importance of Guide-Rail Brackets:Guide-rails play a vital role in constructing various infrastructures such as highways, bridges, and buildings. They provide necessary support and protection, ensuring the safety of workers and pedestrians alike. However, traditional installation methods often involve time-consuming and labor-intensive processes, leading to potential safety hazards. 2. Introducing the Guide-Rail Bracket System:Recognizing the need for a safer and more efficient solution, the company has developed a revolutionary Guide-Rail Bracket System. Engineered with precision, this system simplifies the installation process while complying with stringent safety standards. 3. Unmatched Features and Benefits:The Guide-Rail Bracket System offers numerous unparalleled features that set it apart from traditional installations. These include:a) Quick and Easy Installation: The brackets are designed to be easily mounted onto existing structures or newly constructed ones, eliminating the need for drilling or other intrusive methods. This reduces installation time by up to 50%, allowing projects to be completed faster.b) Enhanced Safety Measures: The brackets incorporate a robust locking mechanism, providing secure attachment to guide-rails. This prevents accidents caused by loose brackets, ensuring the safety of workers and the public. The brackets themselves are constructed with durable materials, capable of withstanding extreme weather conditions and heavy impacts.c) Flexibility and Adjustability: The Guide-Rail Bracket System offers unparalleled flexibility. With adjustable brackets, it can accommodate various rail sizes and configurations, ensuring compatibility with different construction projects. This adaptability saves time and reduces costs associated with customization.d) Cost Savings and Sustainability: By significantly reducing installation time and labor, the Guide-Rail Bracket System minimizes overall project expenses. Additionally, the eco-friendly design of the brackets promotes sustainability in construction practices, aligning with global environmental goals.4. Approval and Industry Recognition:The Guide-Rail Bracket System has undergone rigorous testing and evaluation, receiving widespread approval from industry experts. It meets and exceeds international safety standards, including those set by regulatory bodies such as the Occupational Safety and Health Administration (OSHA). 5. Testimonials and Success Stories:Several construction companies have already implemented the Guide-Rail Bracket System, reporting remarkable outcomes. These success stories highlight the increased productivity, improved worker safety, and cost savings achieved by adopting this revolutionary solution.6. Future Developments and Expansion:The company remains committed to continuous improvement and innovation. It aims to expand its product line to include additional safety-enhancing solutions for the construction industry. Through ongoing research and development, the company strives to maintain its position as a leader in promoting safety while driving operational efficiency.Conclusion:With the introduction of the Guide-Rail Bracket System, the construction industry is witnessing a paradigm shift in guide-rail installation practices. This groundbreaking solution not only ensures enhanced safety standards but also offers time and cost-saving benefits, thereby revolutionizing the sector. As construction companies embrace these innovative brackets, stakeholders can look forward to a future of increased productivity, minimized hazards, and sustainable construction practices.

Affordable Spiral Conveyor: Evaluating the Cost Factors

Title: The Future of Material Handling: Cutting-Edge Spiral Conveyors Set to Revolutionize the IndustryIntroduction:In an increasingly globalized world, efficient material handling solutions are vital for businesses to streamline their operations and stay ahead of the competition. Recognizing this necessity, several companies have pioneered innovative technologies to optimize logistics and enhance supply chain efficiency. One such revolutionary development is the advent of spiral conveyors, which are poised to revolutionize the material handling sector. With their cost-effective and space-saving design, these cutting-edge conveyors offer businesses unparalleled advantages. In this article, we will explore the world of spiral conveyors, their benefits, and how they are reshaping the landscape of the industry.1. Understanding Spiral Conveyors: Spiral conveyors are a vertical transportation system that efficiently and continuously moves goods between different floor levels. Unlike traditional conveyors, spiral conveyors utilize a unique spiral-shaped belt, enabling them to accomplish greater elevation changes within a confined footprint. This makes them ideal for warehouses and manufacturing facilities with limited floor space. The integration of advanced technology and engineering principles ensures a smooth and seamless transportation process, minimizing the risk of damage to goods.2. Key Advantages of Spiral Conveyors: 2.1 Space Optimization:Spiral conveyors offer a significant advantage over traditional conveyors by efficiently utilizing vertical space. With their compact and spiral design, they occupy less floor area while maximizing storage capacity. By eliminating the need for multiple conveyors or elevators, businesses can optimize their layouts, resulting in a more organized and productive workflow.2.2 Enhanced Efficiency:Spiral conveyors offer continuous material flow, minimizing bottlenecks and reducing manual labor. With a higher throughput capacity, they enable faster and more efficient movement of goods, resulting in reduced production times. Their seamless integration with other automated systems, such as sorting and packaging machinery, further enhances operational efficiency and overall productivity.2.3 Flexibility and Versatility:These state-of-the-art conveyors are engineered to handle a wide range of products, from small and delicate items to heavy and bulky goods. Customizable options, such as variable speed controls and adjustable lane widths, ensure compatibility with diverse industry needs. The adaptability of spiral conveyors makes them a viable solution for various sectors, including manufacturing, e-commerce, pharmaceuticals, and food processing.2.4 Cost-effectiveness:While the initial investment in spiral conveyors may seem higher than traditional conveyors, the long-term cost savings outweigh the initial expenditure. The space-saving design reduces the need for additional infrastructure, resulting in lower construction and maintenance costs. Additionally, the efficient flow of materials minimizes the risk of product damage, reducing operational expenses and increasing overall profitability.3. Industry Leader's Contribution: {}is a renowned innovator in the field of material handling solutions, including the groundbreaking spiral conveyor technology. With years of experience and expertise, they have established themselves as a trusted partner for businesses seeking to optimize their supply chains. By seamlessly integrating their Spiral Conveyor system with cutting-edge software and technologies, {} has transformed material handling processes across industries.4. Future Prospects and Conclusion:The rapid technological advancements in the material handling industry indicate a promising future for spiral conveyors. As businesses worldwide strive for enhanced efficiency, lowered costs, and maximized productivity, the demand for innovative solutions will continue to surge. Spiral conveyors, with their space-saving design, flexibility, and cost-effectiveness, are well-positioned to dominate this evolving market. As companies embrace the benefits of these revolutionary conveyors, they have the potential to reshape the material handling sector and pave the way for even greater advancements in logistics and supply chain management.

Innovative Food Packing Machine Revolutionizes Packaging Industry

Food Packing Machine is a leading company in the food packaging industry, specializing in the design, manufacturing, and distribution of high-quality packaging machinery for food products. With a commitment to excellence and innovation, the company has earned a strong reputation for delivering reliable and efficient packaging solutions to meet the diverse needs of its customers.The company offers a wide range of food packaging machines, including filling machines, sealing machines, labeling machines, and more. These machines are designed to streamline the packaging process, increase productivity, and ensure the quality and safety of the packaged food products. Food Packing Machine's advanced technology and precision engineering set the industry standard for performance and reliability.In addition to its cutting-edge machinery, Food Packing Machine provides comprehensive support and service to its customers. From initial consultation and planning to installation, training, and after-sales support, the company is dedicated to ensuring the success of its customers' packaging operations. With a team of experienced professionals and a commitment to customer satisfaction, Food Packing Machine has become a trusted partner for food producers around the world.Recently, Food Packing Machine has introduced its latest innovation in food packaging technology – the new {} (remove brand name) machine. This state-of-the-art machine incorporates the latest advancements in automation, precision control, and versatile packaging options, making it an ideal solution for food producers looking to enhance their packaging capabilities.The {} (remove brand name) machine is designed to handle a wide range of food products, including dry goods, liquids, powders, and more. Its flexible configuration allows for a variety of packaging styles, including pouches, bags, bottles, and containers, giving producers the flexibility to meet the specific needs of their products and customers.One of the key features of the {} (remove brand name) machine is its advanced control system, which offers precise control over the packaging process to ensure consistency and efficiency. This technology reduces waste, minimizes downtime, and maximizes productivity, ultimately resulting in cost savings for food producers. Additionally, the machine's user-friendly interface and easy-to-use controls make it simple for operators to monitor and adjust the packaging process as needed.Moreover, the {} (remove brand name) machine is equipped with cutting-edge safety features to protect both the operators and the packaged food products. From automated quality checks to secure sealing and tamper-evident packaging, the machine prioritizes the integrity and safety of the packaged food products, meeting the highest industry standards and regulations.With the introduction of the new {} (remove brand name) machine, Food Packing Machine continues to demonstrate its commitment to innovation and excellence in the food packaging industry. The company's dedication to advancing packaging technology and supporting its customers' success positions it as a leader in the global market.As food producers continue to seek efficient and reliable packaging solutions, Food Packing Machine remains a trusted partner, providing top-of-the-line machinery, expert support, and a relentless pursuit of excellence. The new {} (remove brand name) machine is the latest testament to the company's ongoing commitment to setting the standard for food packaging technology.

Newly Designed Drive Sprocket Improves Performance and Durability

Drive Sprocket Company Introduces Innovative Technology for Enhanced PerformanceIn the fast-paced world of industrial and agricultural machinery, the importance of high-quality drive sprockets cannot be overstated. These critical components play a vital role in ensuring that heavy machinery operates at peak performance, and any subpar sprockets can lead to decreased efficiency and costly downtime. Recognizing the need for innovative solutions in this field, Drive Sprocket Company has emerged as an industry leader, offering cutting-edge technology designed to revolutionize the sprocket industry.With a commitment to excellence and a dedication to delivering top-of-the-line products, Drive Sprocket Company has quickly gained a reputation for its unwavering quality and innovation. Founded on the principles of integrity, reliability, and superior craftsmanship, the company has established itself as a trusted partner for businesses operating in a wide range of industries, from construction and mining to agriculture and transportation.At the core of Drive Sprocket Company's success is its relentless pursuit of innovation. The company's research and development team is constantly working to push the boundaries of sprocket technology, seeking out new materials, manufacturing processes, and design enhancements that can deliver unparalleled performance and durability. By investing heavily in cutting-edge machinery and precision engineering capabilities, Drive Sprocket Company has positioned itself at the forefront of the industry, setting new standards for sprocket excellence.One of the key innovations that Drive Sprocket Company has introduced is its proprietary [technology name], a game-changing advancement that promises to elevate the performance of drive sprockets to new heights. This revolutionary technology is the result of years of meticulous research and development, and it represents a significant leap forward in the field of sprocket engineering. By leveraging [technology name], Drive Sprocket Company is able to deliver sprockets that offer unparalleled strength, durability, and reliability, even in the most demanding operating conditions.The [technology name] technology is a testament to Drive Sprocket Company's unwavering commitment to excellence. By incorporating this cutting-edge innovation into its products, the company is able to provide its customers with sprockets that outperform the competition in every way. Whether it's increased load-bearing capacity, enhanced resistance to wear and tear, or improved overall efficiency, [technology name] has cemented Drive Sprocket Company's position as an industry trailblazer, leading the charge towards a new era of sprocket performance.In addition to its groundbreaking [technology name] technology, Drive Sprocket Company also places a strong emphasis on customer satisfaction. The company's team of dedicated professionals is committed to providing exceptional service and support to its clients, ensuring that their unique needs and requirements are met with the utmost care and attention. By fostering strong relationships with its customers and understanding their specific challenges, Drive Sprocket Company is able to develop tailored solutions that address their individual needs, setting the stage for long-term partnerships built on trust and mutual success.As Drive Sprocket Company looks to the future, it remains steadfast in its mission to push the boundaries of sprocket technology and drive continued innovation in the industry. By staying true to its core values of excellence, integrity, and customer focus, the company is poised to build on its success and further solidify its position as a global leader in the sprocket market. With a relentless commitment to innovation and a demonstrated track record of delivering superior products and services, Drive Sprocket Company is well positioned to shape the future of sprocket technology and drive lasting change in the industry.