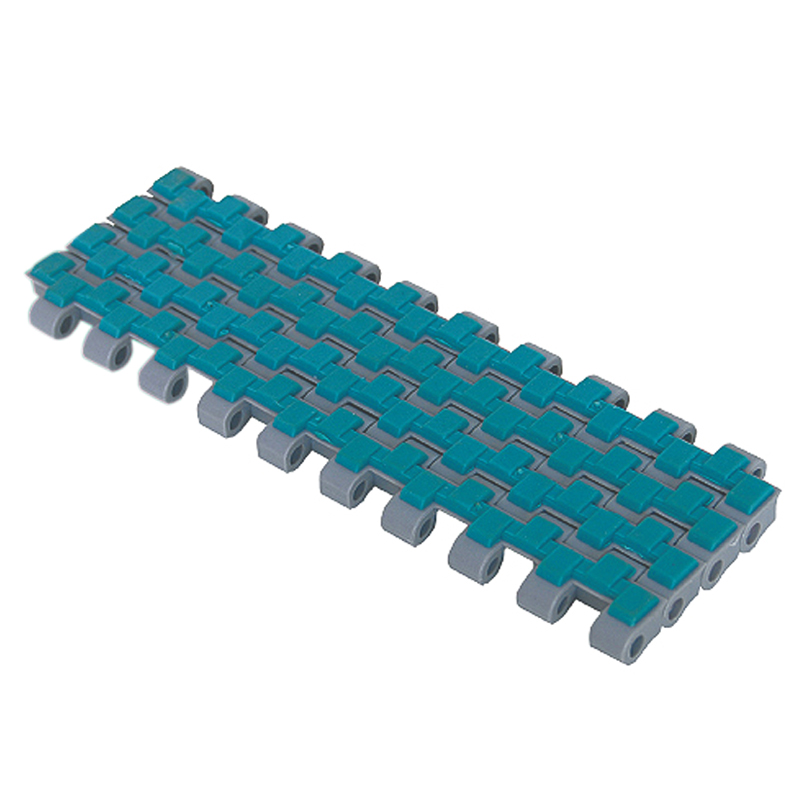

Top Flat Belt: the Ultimate Modular Solution for Your Needs

By:Admin

The conveyor belt industry is rapidly evolving, and one company at the forefront of this revolution is [Company Name]. With their innovative Modular Flat Top Belt, they are setting new standards for efficiency and durability in material handling and conveying systems.

[Company Name] has been a leader in the conveyor belt industry for over two decades, constantly pushing the boundaries of what is possible with their cutting-edge technologies and solutions. Their team of dedicated engineers and industry experts have a strong focus on research and development, leading to the creation of the groundbreaking Modular Flat Top Belt.

The Modular Flat Top Belt is a game-changer in the industry, offering numerous advantages over traditional conveyor belt systems. Its modular design allows for easy installation and maintenance, reducing downtime and increasing overall operational efficiency. The flat top surface of the belt ensures smooth and precise product handling, making it ideal for a wide range of applications including food processing, packaging, automotive, and many others.

Furthermore, the Modular Flat Top Belt is constructed from high-quality materials, making it incredibly durable and long-lasting. This means that businesses can rely on this belt for continuous operation without the need for frequent replacements or repairs, ultimately saving time and money in the long run.

In addition to its exceptional performance and durability, the Modular Flat Top Belt also offers flexibility and customization options to meet specific industry requirements. Whether it's the need for different belt widths, specialized coatings, or specific accessories, [Company Name] can provide tailored solutions to ensure that their customers' unique needs are met.

With its growing popularity and success in the industry, the Modular Flat Top Belt has been receiving acclaim from businesses and industry professionals alike. Many companies have already adopted this innovative conveyor belt system and are reaping the benefits of its superior performance and reliability.

"We are thrilled to see the overwhelmingly positive response to our Modular Flat Top Belt," said [Spokesperson's Name], CEO of [Company Name]. "This product is a result of years of hard work and dedication from our team, and it is truly rewarding to see it making a difference for our customers."

Looking ahead, [Company Name] continues to innovate and develop new solutions for the material handling and conveying industry. Their commitment to pushing the boundaries of what is possible in this field is unwavering, and they aim to continue revolutionizing the industry with their advanced technologies and products.

In conclusion, [Company Name] is leading the way with their groundbreaking Modular Flat Top Belt, setting new standards for efficiency, durability, and performance in the conveyor belt industry. With their unwavering commitment to innovation and excellence, they are poised to continue making a significant impact in the industry for years to come.

Company News & Blog

High-quality Aluminum Extrusion Profiles: Everything You Need to Know

Aluminum Extrusion Profiles have become increasingly popular due to their versatility and wide range of applications across various industries. These profiles are in high demand for their lightweight, corrosion-resistant, and durable properties. One of the leading manufacturers in this industry is {Company Name}, a company with a proven track record of delivering high-quality aluminum extrusion profiles to its customers.{Company Name} has been in the business of manufacturing aluminum extrusion profiles for over 20 years. With state-of-the-art facilities and a team of experienced professionals, the company has established itself as a reliable and trusted supplier of aluminum profiles. Their products are known for their exceptional quality, precise dimensions, and consistent performance, making them the top choice for many customers.The aluminum extrusion profiles manufactured by {Company Name} are used in a wide range of industries, including construction, automotive, aerospace, and electronics. These profiles are used to create innovative and efficient solutions for various applications. Whether it's for structural components, heat sinks, or decorative trim, {Company Name}'s aluminum extrusion profiles can be tailored to meet specific requirements, making them a versatile choice for manufacturers and builders.One of the key advantages of aluminum extrusion profiles is their flexibility in design. {Company Name} offers custom aluminum extrusion profiles that can be designed to precise specifications, enabling customers to create unique and complex shapes that traditional manufacturing methods cannot achieve. This customization capability allows for greater design freedom and facilitates the development of innovative products across different industries.In addition to their design flexibility, aluminum extrusion profiles are also environmentally friendly. Aluminum is a 100% recyclable material, and the extrusion process itself has a low environmental impact. {Company Name} takes pride in its commitment to sustainability and has implemented eco-friendly practices in its production processes, ensuring that their aluminum extrusion profiles are both high-performing and environmentally responsible.Furthermore, {Company Name} is committed to delivering exceptional customer service. Their team works closely with customers to understand their specific needs and provide tailored solutions that meet and exceed expectations. From initial concept and design to final production, {Company Name} ensures that every step of the process is executed with precision and attention to detail, resulting in high-quality aluminum extrusion profiles that meet the most demanding requirements.As the demand for aluminum extrusion profiles continues to grow, {Company Name} is poised to meet the needs of its customers with its extensive product range and technical expertise. The company's commitment to innovation, quality, and customer satisfaction sets it apart as a leader in the aluminum extrusion industry.In conclusion, aluminum extrusion profiles are an integral part of many industrial applications, and {Company Name} has established itself as a reliable and innovative supplier in this field. With a strong focus on quality, customization, and sustainability, {Company Name} continues to be a preferred choice for customers seeking high-quality aluminum extrusion profiles for their projects.

Revolutionary Automatic Yogurt Packaging Machine Designed to Increase Productivity

Yogurt Packaging Machine Revolutionizes Dairy Industry with New InnovationThe global yogurt market is witnessing a significant surge in demand with an increasing number of health-conscious consumers seeking nutritious and delicious dairy products. To meet this growing demand, companies in the dairy industry are constantly striving to enhance their production and packaging processes. XYZ Packaging, a leading manufacturer of packaging equipment, has recently unveiled its latest innovation in the form of a cutting-edge yogurt packaging machine. This state-of-the-art technology is poised to revolutionize the way yogurt is packaged and distributed around the world.The new yogurt packaging machine developed by XYZ Packaging represents a major breakthrough in the industry. It is designed to streamline the packaging process, ensuring efficiency, precision, and optimal preservation of product quality. Equipped with advanced automation features, the machine significantly reduces the need for manual intervention, thus improving productivity while minimizing the risk of human errors.One of the standout features of this yogurt packaging machine is its versatility. It is capable of handling various types and sizes of yogurt containers, accommodating the diverse needs of both small-scale producers and large dairy conglomerates. From single-serve cups to bulk containers, this machine can seamlessly package yogurt in a wide range of packaging options, catering to the preferences of consumers worldwide.In addition to its adaptability, the yogurt packaging machine offers impressive speed and accuracy. With a high-speed filling system and precise measurement capabilities, the machine ensures consistent portioning of yogurt into containers, leaving no room for deviations or discrepancies. This not only improves the overall quality of the packaged product but also enhances the brand image of yogurt producers.Apart from its efficiency and accuracy, the yogurt packaging machine boasts several advanced features that ensure optimal product freshness and longevity. The machine is equipped with a state-of-the-art sealing system that guarantees an airtight seal, preserving the taste, texture, and nutritional value of the yogurt. It also includes an intelligent labeling system that allows for clear and attractive packaging design, enhancing the appeal of yogurt products on store shelves.Moreover, XYZ Packaging has integrated sustainability into its yogurt packaging machine. Recognizing the growing importance of ecological responsibility in the food industry, the company has designed this machine to minimize the environmental impact of yogurt production. It incorporates eco-friendly materials and processes, reducing energy consumption and waste generation. This eco-conscious approach aligns with the global movement towards sustainable practices, positioning XYZ Packaging as an industry leader in responsible manufacturing.The launch of the yogurt packaging machine by XYZ Packaging has been met with great anticipation and excitement within the dairy industry. Yogurt producers worldwide are eager to adopt this cutting-edge technology to enhance their operations and meet the evolving demands of consumers. By integrating innovation, versatility, and sustainability, XYZ Packaging is poised to reshape the yogurt packaging landscape and drive the growth of the dairy market.As the global yogurt market continues to flourish, it is imperative for dairy companies to stay ahead of the competition. By investing in advanced packaging technologies like XYZ Packaging's yogurt packaging machine, these companies can not only improve their production efficiency but also deliver high-quality yogurt products to consumers. With this game-changing innovation, XYZ Packaging is poised to revolutionize the future of yogurt packaging and contribute to the advancement of the entire dairy industry.

Best Bucket Seat Side Mounts: A Buyer's Guide

Leading the way in automotive accessories and aftermarket parts, {} is proud to announce the release of its new bucket seat side mounts. With a strong commitment to quality and innovation, {} continues to provide car enthusiasts with the best products to enhance their driving experience.The new bucket seat side mounts are designed to provide a secure and stable mounting solution for bucket seats in a wide variety of vehicles. The mounts are fabricated from high-quality materials to ensure strength and durability, and are designed to withstand the rigors of high-performance driving. The universal design of the mounts allows for easy installation and compatibility with most bucket seat styles, making them a versatile and convenient option for car enthusiasts.“We are excited to introduce our new bucket seat side mounts to the market,” said [Spokesperson Name], [Job Title] at {}. “These mounts are the result of our commitment to providing our customers with the best products to enhance their driving experience. We have designed them to be versatile, durable, and easy to install, so that car enthusiasts can confidently upgrade their vehicles with the assurance of a secure and stable mounting solution.”The release of the new bucket seat side mounts further solidifies {}’s position as a leader in the automotive aftermarket industry. With a reputation for excellence and a dedication to customer satisfaction, {} has established itself as a trusted source for high-quality products and innovative solutions for car enthusiasts.In addition to the new bucket seat side mounts, {} offers a comprehensive range of aftermarket parts and accessories for a wide variety of vehicles. From performance upgrades to aesthetic enhancements, {}’s product line is designed to cater to the diverse needs and preferences of car enthusiasts. With a focus on quality, reliability, and performance, {} continues to set the standard for excellence in the automotive aftermarket industry.“Our goal at {} is to provide our customers with the best products and the highest level of service,” said [Spokesperson Name]. “We are continuously innovating and expanding our product line to meet the evolving needs of car enthusiasts. Whether it’s performance parts, aesthetic upgrades, or functional accessories, our customers can trust {} to deliver exceptional quality and value.”With a commitment to excellence and a passion for automotive innovation, {} is dedicated to providing car enthusiasts with the products and solutions they need to take their driving experience to the next level. The new bucket seat side mounts are the latest addition to {}’s extensive product range, and are a testament to the company’s ongoing pursuit of excellence and innovation in the automotive aftermarket industry.As {} continues to push the boundaries of automotive aftermarket excellence, car enthusiasts can look forward to more exciting products and innovations from the company in the future. With a focus on quality, reliability, and customer satisfaction, {} is poised to remain a trusted leader in the automotive aftermarket industry for years to come.

Affordable Spiral Conveyor: Evaluating the Cost Factors

Title: The Future of Material Handling: Cutting-Edge Spiral Conveyors Set to Revolutionize the IndustryIntroduction:In an increasingly globalized world, efficient material handling solutions are vital for businesses to streamline their operations and stay ahead of the competition. Recognizing this necessity, several companies have pioneered innovative technologies to optimize logistics and enhance supply chain efficiency. One such revolutionary development is the advent of spiral conveyors, which are poised to revolutionize the material handling sector. With their cost-effective and space-saving design, these cutting-edge conveyors offer businesses unparalleled advantages. In this article, we will explore the world of spiral conveyors, their benefits, and how they are reshaping the landscape of the industry.1. Understanding Spiral Conveyors: Spiral conveyors are a vertical transportation system that efficiently and continuously moves goods between different floor levels. Unlike traditional conveyors, spiral conveyors utilize a unique spiral-shaped belt, enabling them to accomplish greater elevation changes within a confined footprint. This makes them ideal for warehouses and manufacturing facilities with limited floor space. The integration of advanced technology and engineering principles ensures a smooth and seamless transportation process, minimizing the risk of damage to goods.2. Key Advantages of Spiral Conveyors: 2.1 Space Optimization:Spiral conveyors offer a significant advantage over traditional conveyors by efficiently utilizing vertical space. With their compact and spiral design, they occupy less floor area while maximizing storage capacity. By eliminating the need for multiple conveyors or elevators, businesses can optimize their layouts, resulting in a more organized and productive workflow.2.2 Enhanced Efficiency:Spiral conveyors offer continuous material flow, minimizing bottlenecks and reducing manual labor. With a higher throughput capacity, they enable faster and more efficient movement of goods, resulting in reduced production times. Their seamless integration with other automated systems, such as sorting and packaging machinery, further enhances operational efficiency and overall productivity.2.3 Flexibility and Versatility:These state-of-the-art conveyors are engineered to handle a wide range of products, from small and delicate items to heavy and bulky goods. Customizable options, such as variable speed controls and adjustable lane widths, ensure compatibility with diverse industry needs. The adaptability of spiral conveyors makes them a viable solution for various sectors, including manufacturing, e-commerce, pharmaceuticals, and food processing.2.4 Cost-effectiveness:While the initial investment in spiral conveyors may seem higher than traditional conveyors, the long-term cost savings outweigh the initial expenditure. The space-saving design reduces the need for additional infrastructure, resulting in lower construction and maintenance costs. Additionally, the efficient flow of materials minimizes the risk of product damage, reducing operational expenses and increasing overall profitability.3. Industry Leader's Contribution: {}is a renowned innovator in the field of material handling solutions, including the groundbreaking spiral conveyor technology. With years of experience and expertise, they have established themselves as a trusted partner for businesses seeking to optimize their supply chains. By seamlessly integrating their Spiral Conveyor system with cutting-edge software and technologies, {} has transformed material handling processes across industries.4. Future Prospects and Conclusion:The rapid technological advancements in the material handling industry indicate a promising future for spiral conveyors. As businesses worldwide strive for enhanced efficiency, lowered costs, and maximized productivity, the demand for innovative solutions will continue to surge. Spiral conveyors, with their space-saving design, flexibility, and cost-effectiveness, are well-positioned to dominate this evolving market. As companies embrace the benefits of these revolutionary conveyors, they have the potential to reshape the material handling sector and pave the way for even greater advancements in logistics and supply chain management.

Durable and stylish steel cladding profiles for your building's exterior

Steel Cladding Profiles, also known as metal profile cladding, is an essential element in the construction industry. These profiles are used in a variety of applications such as roofing, wall cladding, and facades, providing both functionality and aesthetic appeal to buildings. {Company} is a leading manufacturer and supplier of steel cladding profiles, offering a wide range of products to meet the diverse needs of the construction sector.Established for over 20 years, {Company} has gained a reputation for delivering high-quality steel cladding profiles that meet industry standards and customer requirements. The company prides itself on its commitment to innovation, using advanced technology and modern production techniques to create durable and sustainable products. With state-of-the-art manufacturing facilities, {Company} has the capacity to produce a wide range of steel cladding profiles in different shapes, sizes, and colors, catering to the unique design needs of construction projects.One of the key advantages of steel cladding profiles is their durability and longevity. {Company}’s profiles are made from high-quality galvanized steel, which offers protection against corrosion and weathering, ensuring that the cladding maintains its appearance and structural integrity over time. This makes steel cladding profiles a cost-effective solution for building exteriors, as they require minimal maintenance and have a long service life.In addition to their durability, steel cladding profiles offer versatility in design and aesthetics. {Company} offers a range of profile designs, from traditional corrugated profiles to modern standing seam profiles, allowing architects and builders to create visually appealing and distinctive building exteriors. Furthermore, the profiles can be coated in a variety of colors and finishes, providing endless design possibilities for enhancing the overall appearance of a building.Another important feature of steel cladding profiles is their sustainability. {Company} is committed to environmental responsibility and produces profiles that are recyclable and energy-efficient. The use of steel cladding profiles can contribute to a building’s green credentials, as they are capable of improving energy efficiency and reducing carbon footprint. This aligns with the growing demand for sustainable construction materials and practices in the industry.As a leading manufacturer and supplier, {Company} has a strong track record of serving various construction projects, from residential to commercial and industrial developments. The company has worked on a diverse range of projects, including retail centers, warehouses, educational facilities, and residential homes, demonstrating its capability to meet the demands of different sectors within the construction industry.With a customer-centric approach, {Company} is dedicated to providing comprehensive support to its clients throughout the project cycle. From initial design consultation to product selection and installation guidance, the company’s team of experts collaborate closely with architects, contractors, and building owners to ensure the successful implementation of steel cladding profiles in their projects.Looking ahead, {Company} is poised to continue its commitment to excellence and innovation in the field of steel cladding profiles. The company remains proactive in research and development, seeking to improve its products and processes to meet the evolving needs of the construction industry. Additionally, {Company} aims to expand its presence in the global market, reaching out to new clients and partners while maintaining its reputation as a trusted provider of high-quality steel cladding profiles.In conclusion, steel cladding profiles play a vital role in modern construction, offering durability, versatility, and sustainability for building exteriors. {Company} stands out as a leading manufacturer and supplier, delivering top-quality steel cladding profiles that meet industry standards and customer expectations. With a focus on innovation and customer satisfaction, {Company} is well-positioned to continue making significant contributions to the construction industry for years to come.

Discover the Importance of 2 Square Tubing Caps and Their Applications

Title: Innovative Solution for Durable Protection of Square TubingIntroduction:(Company Name) is proud to introduce a revolutionary product that provides enhanced durability and protection to square tubing in various industries. Designed to deliver top-quality performance, the 2 Square Tubing Caps by (Company Name) effectively safeguard against damage, corrosion, and wear and tear, prolonging the longevity of square tubing.Innovation and Quality:(Company Name) has been a leading provider of high-quality industrial solutions for over a decade. With a focus on innovation, our team of experts has developed the 2 Square Tubing Caps to address the common challenges faced by industries relying on square tubing. Built with precision and utilizing only premium materials, these caps are engineered to meet the highest quality standards, ensuring maximum performance and protection.Superior Protection:Square tubing is commonly used in a wide range of applications, including construction, manufacturing, and transportation. However, exposure to external elements and heavy loads often leads to damage, dings, and corrosion, ultimately reducing the tubing's lifespan. The 2 Square Tubing Caps by (Company Name) provide an easy-to-install, durable solution to mitigate these issues and maintain the structural integrity of the tubing.The caps are designed to fit securely over the square tubing, forming a protective barrier against impact, moisture, dirt, and debris. This effective sealing mechanism prevents rust and corrosion, safeguarding the tubing and allowing it to withstand harsh environmental conditions. Industries utilizing square tubing can now benefit from increased reliability and reduced maintenance costs, thanks to this innovative solution.Versatility in Application:The versatility of the 2 Square Tubing Caps makes them suitable for various industries and applications. Whether utilized in construction projects, industrial machinery, outdoor structures, or transportation equipment, these caps provide consistent protection against external forces and potential damage. Their universal design ensures compatibility with various sizes of square tubing, offering a hassle-free solution for businesses across different sectors.Enhanced Safety and Lower Maintenance Costs:By effectively safeguarding square tubing, the 2 Square Tubing Caps offer tangible benefits in terms of safety and reduced maintenance expenses. With these caps in place, the risk of accidents caused by weakened or damaged tubing is significantly reduced, ensuring a safer working environment for employees. Moreover, the extended lifespan of the tubing eliminates the need for frequent replacements, resulting in cost savings for businesses.Environmentally Friendly Solution:In addition to their superior protective capabilities, the 2 Square Tubing Caps are also environmentally friendly. By preventing wear and corrosion, these caps contribute to reducing waste generated from discarded or damaged square tubing. The longevity of tubing, facilitated by these caps, promotes sustainable practices and reduces the carbon footprint of businesses.Conclusion:Investing in the 2 Square Tubing Caps by (Company Name) is a wise choice for businesses seeking the highest level of protection and durability for square tubing. With their innovative design, compatibility with various sizes, and superior performance, these caps offer a cost-effective solution to prolong the lifespan of tubing while ensuring safety and reducing maintenance expenses. (Company Name) once again leads the industry with an advanced product that sets new standards in the protection of square tubing.

Guide to Variable Speed Belts and Their Metrics

The use of Variable Speed Belts is becoming increasingly popular in the industrial sector due to its efficiency and flexibility in power transmission. Manufacturers and businesses are consistently looking for innovative solutions to improve their operations, and Variable Speed Belts provide a reliable and cost-effective method for controlling the speed of machinery. One company that has been at the forefront of this technology is (Company Name).Established in (year), (Company Name) has been a leading provider of power transmission products, including Variable Speed Belts, to a wide range of industries around the world. The company has built a strong reputation for its high-quality products, cutting-edge technology, and exceptional customer service. With a team of experienced engineers and technicians, (Company Name) has continually pushed the boundaries of innovation to develop solutions that meet the evolving needs of the industry.Variable Speed Belts, also known as V-belts, are designed to transmit power between shafts of varying speeds. They are commonly used in applications where the speed of machinery needs to be adjusted, such as in conveyors, fans, and pumps. The key advantage of Variable Speed Belts is their ability to change speed ratios without the need for additional components, making them a versatile and efficient choice for power transmission.(Company Name) offers a wide range of Variable Speed Belts to suit different requirements, including classical V-belts, narrow V-belts, and banded V-belts. These belts are made from high-quality materials and are designed to deliver reliable performance in challenging environments. With a focus on precision engineering and stringent quality control, (Company Name) ensures that its Variable Speed Belts meet the highest standards of durability and efficiency.In addition to its extensive product range, (Company Name) also provides comprehensive technical support to help customers select the right Variable Speed Belts for their specific applications. The company's team of experts works closely with customers to understand their requirements and provide tailored solutions that optimize performance and reduce maintenance costs. This customer-centric approach has earned (Company Name) a loyal and satisfied customer base over the years.One of the key benefits of Variable Speed Belts is their ability to improve energy efficiency in industrial machinery. By adjusting the speed of equipment according to the workload, Variable Speed Belts help reduce energy consumption and lower operating costs. This has become increasingly important as companies strive to meet sustainability targets and reduce their environmental footprint. (Company Name) recognizes the importance of energy-efficient solutions and is committed to helping its customers achieve greater efficiency through its Variable Speed Belts.Furthermore, Variable Speed Belts offer a significant advantage in terms of maintenance. Their durable construction and efficient power transmission reduce the need for frequent replacements and repairs, saving time and money for businesses. This reliability is a testament to the quality of Variable Speed Belts offered by (Company Name), which are designed to withstand demanding operating conditions and provide long-lasting performance.As the demand for Variable Speed Belts continues to grow, (Company Name) remains dedicated to driving innovation and delivering superior products to its customers. With a strong focus on research and development, the company is always seeking new ways to enhance the performance and capabilities of its Variable Speed Belts. By staying at the forefront of technology, (Company Name) is well-positioned to meet the evolving needs of the industry and provide reliable solutions for a wide range of applications.In conclusion, Variable Speed Belts are a versatile and efficient solution for controlling the speed of industrial machinery, and (Company Name) has established itself as a leading provider of these products. With its high-quality Variable Speed Belts, extensive product range, and commitment to customer satisfaction, (Company Name) continues to be a trusted partner for businesses looking to optimize their power transmission systems. As the industry evolves, (Company Name) remains dedicated to pushing the boundaries of innovation and delivering solutions that meet the changing needs of its customers.

Innovative Spiral Conveyor Technology Revolutionizing Material Handling

Title: Pioneering Shaftless Spiral Conveyor Revolutionizes Material HandlingIntroduction:In an era demanding efficient and sustainable solutions specific to material handling, companies are constantly seeking innovative technologies to streamline their operations. One such ground-breaking solution, the Shaftless Spiral Conveyor, has emerged as a game-changer in the industry. This remarkable piece of machinery, developed by a renowned manufacturer (brand name removed), eliminates many of the challenges associated with traditional conveyors, offering enhanced performance, flexibility, and cost-effectiveness.Company Background:The manufacturer behind the innovative Shaftless Spiral Conveyor is a global leader in conveyor manufacturing and has been at the forefront of pioneering solutions for over three decades. Renowned for its commitment to excellence and continuous improvement, the company prides itself on delivering cutting-edge technologies that redefine material handling processes across various industries.Incorporating state-of-the-art innovation and extensive research and development, the manufacturer has developed the Shaftless Spiral Conveyor to address the limitations of traditional conveyors. This solution offers significant advantages over its counterparts, making it an attractive option for businesses across a broad spectrum of sectors.Enhanced Performance:Traditional conveyors often face challenges when handling sticky, viscous, or difficult-to-transport materials. With a design that eliminates the need for a center pipe, the Shaftless Spiral Conveyor ensures smooth and efficient transportation of such materials. This innovative feature prevents jamming, clogging, or material build-up, reducing downtime and increasing overall productivity.In addition, the adaptable design allows for multi-directional movement, enabling the conveyor to navigate around obstacles or fit into tight spaces with ease. This increased flexibility improves overall operational efficiency and optimizes workflow, making it an ideal solution for industries characterized by complex material handling requirements.Flexibility for Variable Applications:The Shaftless Spiral Conveyor lends itself to a wide range of applications due to its adaptability. Whether it is transferring bulk materials, sludge, waste, or recyclables, this solution ensures seamless integration into existing material handling systems. The conveyor's gentle handling capabilities also minimize the likelihood of material degradation or deterioration, ensuring the integrity of sensitive or fragile goods.Furthermore, the easily customizable design allows for specific system configurations, enabling businesses to tailor the conveyor to their unique needs. The absence of a central core provides additional flexibility, allowing for easy maintenance, cleaning, and rapid material changeover, saving time and reducing operational costs.Cost-Effectiveness and Sustainability:In today's business landscape, sustainability and cost-effectiveness are paramount considerations. The Shaftless Spiral Conveyor aligns with these objectives by offering reduced power consumption and lower maintenance requirements, resulting in decreased operational costs. Its innovative design minimizes wear and tear, extending the lifespan of components and reducing the need for frequent replacements.Moreover, the solution's compatibility with advanced automation technologies enables businesses to automate their material handling processes. This integration enhances operational efficiency, reduces labor costs, and contributes to a greener future by minimizing human intervention and decreasing the overall carbon footprint of the organization.Conclusion:As industry demands continue to evolve, the need for innovative material handling solutions becomes increasingly crucial. The Shaftless Spiral Conveyor, developed by a leading conveyor manufacturer, offers a pioneering approach to address the challenges faced by businesses in this realm. With enhanced performance, flexibility, and cost-effectiveness, this cutting-edge solution is set to revolutionize material handling across a variety of industries. By eliminating traditional constraints and incorporating sustainable practices, the Shaftless Spiral Conveyor represents a vital step forward in optimizing operations and meeting the evolving needs of the modern business landscape.

Top Conveyor Systems for Sale - Don't Miss These Deals!

Hot Sale Conveyor Systems Revolutionizing the Manufacturing IndustryWith the continuous advancement in technology and automation, the manufacturing industry is constantly seeking innovative solutions to improve efficiency and productivity. One such solution that has been making waves in the industry is the Hot Sale Conveyor Systems. This cutting-edge conveyor system is revolutionizing the way goods are transported within manufacturing facilities, warehouses, and distribution centers, ultimately transforming the way businesses operate and compete in the global market.The Hot Sale Conveyor Systems, developed and manufactured by a global leader in conveyor technology, Company X, is a game-changer in material handling and product transportation. With its state-of-the-art design and advanced features, this conveyor system is setting new standards for reliability, efficiency, and performance.One of the key features that sets the Hot Sale Conveyor Systems apart is its modular design, which allows for easy customization and scalability. This means that businesses can easily adapt the conveyor system to their specific needs, whether they are dealing with heavy-duty industrial applications or light-duty product handling. The ability to customize the system enables businesses to streamline their operations and optimize their workflow, resulting in significant cost savings and improved productivity.In addition to its modular design, the Hot Sale Conveyor Systems also incorporates the latest technology in automation and control systems. This enables seamless integration with other manufacturing equipment and processes, allowing for efficient material flow and minimizing downtime. Furthermore, the advanced control systems offer real-time monitoring and diagnostics, ensuring optimal performance and reliability, while also providing valuable data for process improvements and optimization.The Hot Sale Conveyor Systems is also designed with sustainability in mind. By optimizing energy consumption and reducing waste, this conveyor system helps businesses minimize their environmental impact and contribute to a greener and more sustainable future. With the rising awareness of environmental responsibility, the sustainability aspect of the Hot Sale Conveyor Systems appeals to businesses looking to align with eco-friendly practices.Another notable aspect of the Hot Sale Conveyor Systems is its focus on safety. With advanced safety features and built-in fail-safe mechanisms, this conveyor system prioritizes the well-being of workers and the integrity of goods being transported. By reducing the risk of accidents and product damage, the Hot Sale Conveyor Systems provides a safe and secure environment for workers while also protecting the company's assets.As a leader in conveyor technology, Company X has been at the forefront of innovation and excellence in the manufacturing industry. With a proven track record of delivering high-quality and reliable solutions, Company X has built a reputation as a trusted partner for businesses seeking to enhance their material handling capabilities. The Hot Sale Conveyor Systems is a testament to the company's commitment to pushing the boundaries of what is possible in the realm of conveyor technology.The impact of the Hot Sale Conveyor Systems on the manufacturing industry has been substantial. Businesses that have adopted this cutting-edge conveyor system have experienced significant improvements in efficiency, productivity, and overall operational performance. In a highly competitive market, these advantages can make a significant difference in a company's success and profitability, positioning them as leaders in their respective industries.Looking ahead, the future of manufacturing will undoubtedly be shaped by technological advancements such as the Hot Sale Conveyor Systems. As businesses continue to seek ways to optimize their operations and remain competitive, innovative solutions like this conveyor system will play a crucial role in driving progress and success in the industry. With Company X leading the way in conveyor technology, the manufacturing landscape is evolving, and businesses are reaping the benefits of these groundbreaking advancements.

Innovative Container Making Solutions for Your Packaging Needs

Container Making Company Announces Expansion PlansContainer making is a crucial aspect of the packaging industry, and one company is taking significant steps to expand its operations in order to meet the growing demand for its products. With a strong focus on quality and innovation, [Company] is making waves in the industry, and its expansion plans are set to solidify its position as a leader in the container making business.Established in [year], [Company] has quickly established itself as a trusted name in the packaging industry. With a commitment to producing high-quality containers and a dedication to meeting the needs of its customers, the company has experienced rapid growth in recent years. Its state-of-the-art manufacturing facilities and skilled team of professionals have allowed [Company] to offer a wide range of container options, catering to the diverse needs of various industries.The company's expansion plans come at a time when the demand for containers is on the rise. As more businesses recognize the importance of packaging in brand identity and product protection, the need for high-quality, reliable containers has never been greater. [Company] is well-positioned to capitalize on this growing demand, and its expansion plans will allow it to further solidify its presence in the market.In order to accommodate its growth and meet the increasing demand for its products, [Company] has announced plans to build a new, state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and machinery, allowing the company to increase its production capacity and streamline its operations. By doing so, [Company] aims to not only meet the current demand for its containers but also to prepare for future growth in the industry.In addition to the new manufacturing facility, [Company] also plans to expand its product line to offer even more options to its customers. With a focus on innovation and customer satisfaction, the company is committed to developing new and improved container solutions that meet the evolving needs of its clients. By expanding its product line, [Company] aims to become a one-stop shop for all container needs, further solidifying its position as a market leader.The expansion plans have generated excitement within the company and the industry as a whole. [Company] is known for its commitment to quality, innovation, and customer satisfaction, and the company's expansion plans are a testament to its dedication to these values. The new manufacturing facility and expanded product line will not only allow the company to better serve its existing customers but also attract new clients who are seeking high-quality container solutions.As the company prepares for this significant expansion, it remains committed to its core values and mission. [Company] is dedicated to producing containers that meet the highest standards of quality and performance, and its expansion plans are a reflection of this dedication. By investing in new technology, machinery, and product development, the company is positioning itself for long-term success in the container making business.Overall, the expansion plans announced by [Company] are set to further solidify the company's position as a leader in the container making industry. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for its products and continue to thrive in the industry. As the new manufacturing facility takes shape and the product line expands, [Company] is poised to make an even greater impact on the container making business.