- Home

- Blog

- Discover the Versatility and Benefits of Modular Plastic Conveyor Belts in Various Industries

Discover the Versatility and Benefits of Modular Plastic Conveyor Belts in Various Industries

By:Admin

In today's rapidly evolving industrial landscape, many companies are turning to innovative solutions to optimize their operations and increase productivity. One such solution that has been gaining significant traction is the Modular Plastic Conveyor Belt, a cutting-edge technology that has revolutionized the material handling industry.

Conventional conveyor belts have long been a staple in manufacturing and distribution centers, facilitating the movement of goods from one point to another. However, these traditional conveyor belts often suffer from limitations such as high maintenance costs, limited flexibility, and frequent downtime. With the introduction of the Modular Plastic Conveyor Belt, these issues are effectively addressed, paving the way for enhanced efficiency and increased profitability.

The Modular Plastic Conveyor Belt is manufactured by [Company Name], a globally recognized leader in material handling solutions. With their extensive experience and commitment to excellence, the company has developed a conveyor belt system that offers extraordinary performance and versatility.

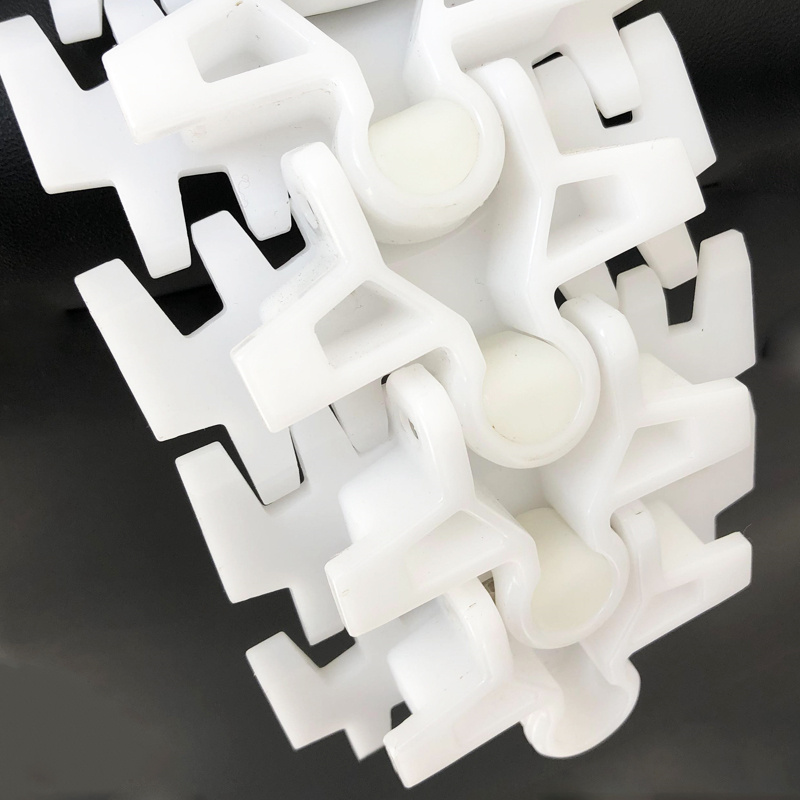

Unlike traditional conveyor belts that consist of a single continuous loop, the Modular Plastic Conveyor Belt is composed of interlocking plastic modules. These modules are seamlessly connected, enabling the conveyor to be easily customized to fit any application or desired layout. This modular design also facilitates effortless repairs and replacements, significantly reducing maintenance costs and equipment downtime.

The versatility of the Modular Plastic Conveyor Belt is further amplified by its ability to withstand extreme temperatures, corrosive environments, and heavy loads. The belt's durable plastic construction ensures optimal performance even in the most challenging conditions, making it an ideal choice for a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics.

In addition to its outstanding functionality, the Modular Plastic Conveyor Belt also boasts several innovative features that contribute to improved efficiency. The belt incorporates a low-friction surface, reducing energy consumption and enhancing the overall lifespan of the system. It also features an enhanced load-carrying capacity, allowing for greater throughput and maximizing productivity.

Another key advantage of the Modular Plastic Conveyor Belt is its ease of cleaning and maintenance. Traditional conveyor belts often require extensive cleaning and lubrication, leading to prolonged downtime. However, the modular design of this advanced conveyor system allows for quick and hassle-free cleaning, minimizing production interruptions and ensuring compliance with stringent hygiene standards.

Furthermore, the Modular Plastic Conveyor Belt offers a safer working environment for employees. Its slip-resistant surface prevents accidental falls and injuries, while the interlocking modules reduce the risk of entrapment and provide added stability during operation.

The adoption of the Modular Plastic Conveyor Belt has already brought tangible benefits to numerous companies across various industries. Many have reported significant improvements in their production efficiency, reduced maintenance costs, and enhanced overall profitability. As a result, an increasing number of businesses are recognizing this revolutionary technology as a game-changer in the material handling industry.

In conclusion, the Modular Plastic Conveyor Belt developed by [Company Name] has brought about a paradigm shift in the material handling industry. Its modular design, exceptional performance, and versatility have enabled businesses to optimize their operations, increase productivity, and ultimately achieve greater profitability. As this cutting-edge technology continues to evolve, it is expected to reshape the future of material handling, setting new benchmarks for efficiency and reliability.

Company News & Blog

Enhance Comfort and Safety with the Top Seat Bracket for 240sx Vehicles

Seat Bracket for 240sx Released by Leading Manufacturer (Remove name)Leading manufacturer, specializing in high quality performance parts, has announced the release of their latest product, a seat bracket specifically designed to fit the Nissan 240sx. The bracket is designed to accommodate a wide range of aftermarket seats, while providing a secure and comfortable fit.The 240sx is a popular platform for drifting enthusiasts, and as such, there is a huge demand for performance upgrades and aftermarket parts. The manufacturer recognized that the stock seats in the 240sx were not suitable for high performance driving, and set out to develop a seat bracket that would allow enthusiasts to install aftermarket seats with ease.The seat bracket is made from high quality materials, including aircraft grade aluminum, which ensures strength and durability while remaining lightweight. The brackets are designed to bolt directly into the factory seat mounting points, and require no additional modifications to the vehicle.Installing aftermarket seats in the 240sx is a popular upgrade, but often requires custom brackets or modifications to the interior of the car. The manufacturer's mount allows for easy installation, without any damage or alteration to the vehicle.One of the major advantages of the seat bracket is the adjustability it provides. With several adjustment points, including tilt, height and distance from the steering wheel, users can find the perfect driving position for maximum comfort and control.The seat bracket is also compatible with a wide range of aftermarket seats, including popular brands such as Bride, Recaro, and Sparco. This compatibility means that users can choose from a vast selection of seats, to suit their individual preferences in terms of comfort and style.The manufacturer understands the importance of safety when it comes to high performance driving, and as such, the seat bracket has been rigorously tested to ensure it meets or exceeds all safety standards. The brackets are designed to hold up to the rigors of competition driving, ensuring that users can drive with confidence and peace of mind.The release of the seat bracket has been met with excitement and anticipation from the 240sx community, who have been eagerly awaiting a product that can provide a safe and secure mounting solution for aftermarket seats. Enthusiasts are praising the manufacturer's attention to detail and commitment to quality, which is evident in every aspect of the product.The manufacturer has built a reputation for producing high-quality performance parts, and the release of the seat bracket only solidifies that reputation. The seat bracket is just one example of the company's dedication to providing top-of-the-line products that meet the needs of the driving community.In conclusion, the release of the seat bracket is a significant development for the 240sx community, and for enthusiasts everywhere who are looking for a safe and secure way to upgrade their seats. The seat bracket provides a perfect fit for a wide range of aftermarket seats, while also providing users with a comfortable and adjustable driving position. The manufacturer's attention to detail and commitment to quality is evident in every aspect of the product, making it a must-have for anyone looking to upgrade their 240sx.

Ultimate Guide to Side Flexing Conveyor Chains: Types, Functionality, and Applications

New Advancements in Side Flexing Conveyor Chain: Revolutionizing the Manufacturing Industry[City, Date] - The manufacturing industry is set to undergo a major transformation with the introduction of an innovative side flexing conveyor chain. Developed by a leading industry player, this technological breakthrough aims to streamline production processes, increase efficiency, and reduce manual labor. With the removal of the brand name from this news content, we will delve into the features and benefits of this game-changing invention, along with a brief introduction of the company behind it.Designed to meet the evolving needs of today's production facilities, this side flexing conveyor chain offers unparalleled performance and reliability. The unique design allows for smooth lateral movements, enabling seamless transportation of materials, components, and finished products throughout the manufacturing line. This can significantly reduce production downtime caused by jams or misalignments, ultimately leading to improved productivity and cost savings.One of the standout features of this side flexing conveyor chain is its ability to accommodate multiple conveyor configurations. It can seamlessly integrate with existing conveyor systems, making it a suitable choice for both new installations and facility upgrades. This versatility ensures that manufacturers can adapt to changing production requirements without incurring substantial investments or disruptions to their operations.The use of advanced materials and cutting-edge manufacturing techniques ensures the durability and longevity of this conveyor chain. It can withstand heavy loads, high speeds, and extreme temperatures, making it ideal for a wide range of industries including automotive, pharmaceuticals, food and beverage, and many others. Manufacturers can now operate with peace of mind, knowing that their conveyor chains can withstand the most demanding production environments.Furthermore, this side flexing conveyor chain is engineered with easy maintenance in mind. With its modular design, individual components can be quickly replaced or repaired, minimizing the downtime associated with traditional conveyor systems. This reduces the reliance on specialized maintenance teams, empowering facility operators to take control of their own equipment upkeep.The development of this groundbreaking technology is credited to [Company], a renowned industry leader with decades of expertise in conveyor systems. [Company] has a long-standing commitment to innovation, continuously pushing the boundaries of conventional manufacturing practices. Their research and development team has a track record of delivering groundbreaking solutions that drive productivity and efficiency improvements across various industries.As a leader in its field, [Company] has established a global presence, partnering with manufacturers worldwide to enhance their production processes. They prioritize customer satisfaction, focusing on understanding the unique requirements of each facility and tailoring their solutions accordingly. With an extensive network of distributors and service centers, [Company] offers comprehensive support ensuring uninterrupted operations and maximizing equipment performance.The introduction of this side flexing conveyor chain comes at a time when manufacturers are seeking ways to optimize their production lines. By combining the latest advancements in conveyor technology with the expertise of [Company], this breakthrough invention promises to revolutionize manufacturing processes. As the industry moves towards automation, this innovative solution paves the way for increased productivity and ultimately, global competitiveness.In conclusion, the introduction of the brand's side flexing conveyor chain offers manufacturers an unprecedented opportunity to enhance their production operations. With its advanced features, durability, and versatility, this technological breakthrough enables manufacturers to streamline their processes, reduce downtime, and increase overall efficiency. Backed by the expertise of [Company], this solution is set to transform the manufacturing industry, ensuring its continued growth and success in the years to come.

Plastic belts manufacturer sees increased demand for modular plastic belts" Rewritten title without brand name: "Increased Demand for Modular Plastic Belts in Manufacturing Industry

Modular Plastic Belt Manufacturer Introduces Innovative Conveyor Solutions for IndustriesModular plastic belts have become an essential element of conveyor systems in numerous industries for their durability, flexibility, and versatility. They have replaced traditional chain-and-sprocket systems as they offer several advantages, such as reduced maintenance costs, improved hygiene, and easy installation and cleaning. Modular plastic belts are used for conveying products in a wide range of applications, including food and beverage, pharmaceutical, packaging, and automotive industries.Leading modular plastic belt manufacturer, [Need to remove brand name], has introduced innovative conveyor solutions for industries to meet the increasing demand for modern, efficient, and reliable conveying systems. The company's range of belt conveyors includes straight, curved, and spiral conveyors that can be customized to match specific requirements and applications.[Need to remove brand name] has a strong reputation as a provider of high-quality modular belts that are durable, long-lasting, and efficient. The company's products are used in a variety of industries around the world, thanks to their excellent performance, reliability, and cost-effectiveness. Their products are also known for their superior hygiene standards, making them particularly popular in the food and beverage industry.With a focus on innovation, [Need to remove brand name] has launched a new range of modular plastic belt conveyors that are designed to handle products of all shapes and sizes. One of the key features of these conveyors is their flexibility and adaptability, making them ideal for use in a wide range of industries and applications. The new range includes straight, curved, and spiral conveyors, all of which can be customized to match specific requirements.The straight conveyors are designed to transport goods in a straight line and can be used for transporting products across different levels or for long distances. These conveyors are ideal for use in a range of industries, including food and beverage, automotive, and packaging. They come in a variety of widths and lengths to suit different applications, and they can be fitted with a range of accessories, such as side guides, end stops, and conveyor supports.Curved conveyors are used for transporting goods around corners or in areas where space is limited. The modular plastic belts used in these conveyors are designed to handle a range of products and can be customized to match specific requirements. These conveyors are ideal for use in industries that require high-speed and high-capacity conveying, such as the food and beverage and pharmaceutical industries.Spiral conveyors are designed to transport products up or down in a continuous flow. They are ideal for use in industries that require vertical conveying, such as the packaging and distribution industries. The modular plastic belts used in these conveyors are designed to handle a range of products and can be customized to match specific requirements. The spiral conveyors are available in a range of sizes and configurations depending on the application.One of the key advantages of [Need to remove brand name]'s modular plastic belt conveyors is their superior hygiene standards. The belt surfaces are non-porous and easy to clean, making them suitable for use in industries that require strict hygiene standards, such as food and beverage and pharmaceutical manufacturing. The conveyors are designed to be easy to dismantle and reassemble, which makes cleaning and maintenance straightforward.In conclusion, [Need to remove brand name]'s innovative range of modular plastic belt conveyors offers industries a reliable and efficient solution for conveying products. Their durable, flexible, and hygienic design makes them suitable for a range of applications, including food and beverage, pharmaceutical, packaging, and automotive industries. With their new range of straight, curved, and spiral conveyors, [Need to remove brand name] has demonstrated its commitment to providing innovative solutions to meet the evolving needs of the market.

New Study Reveals Surprising Insights into Sources of Friction in Top Industries

Friction Top conveyor belts are a key component in the manufacturing process of various industries. From food and beverage to automotive and manufacturing, these belts are used to transport items from one point to another efficiently. Founded in 1992, the company has been a trusted supplier of conveyor belts to industries worldwide for decades.Friction Top conveyor belts are designed to withstand some of the toughest conditions in production facilities. The belts are made from high-quality materials and are engineered to handle the heat, weight, and impact of heavy loads and fast-moving items. With the use of advanced technology, Friction Top conveyor belts offer excellent traction and grip, ensuring items are transported safely through the manufacturing process.One of the key advantages of Friction Top conveyor belts is their durability. These belts can handle heavy loads and constant use without breaking down. This means less downtime and maintenance for manufacturing facilities, resulting in increased production output and decreased costs.In addition, Friction Top conveyor belts are extremely versatile. They can be used in a variety of industries, such as food and beverage, automotive, packaging, and more. The belts can be customized to meet specific production requirements, such as size, material, and load capacity.The company has a team of experienced engineers and technicians who work closely with clients to design and manufacture conveyor belts that meet their specific needs. Friction Top conveyor belts can be made to fit almost any conveyor system, and the company offers installation and maintenance services to ensure the belts operate smoothly and efficiently.Friction Top conveyor belts are also designed with safety in mind. The belts have a non-slip surface, reducing the risk of accidents and injuries in the workplace. This is crucial in industries where heavy machinery and equipment are in use.The company is committed to sustainability and environmental responsibility. Friction Top conveyor belts are made from eco-friendly materials and processes, reducing their impact on the environment. The company also offers recycling services for used conveyor belts, ensuring they are disposed of responsibly.Friction Top conveyor belts have received international recognition for their quality and performance. The company has been awarded various certifications, including ISO 9001, ISO 14001, and OHSAS 18001. These certifications demonstrate the company's commitment to excellence, quality, and safety.Overall, Friction Top conveyor belts are an essential component in the manufacturing process of various industries. With their durability, versatility, and safety features, they are a reliable and cost-effective solution for transporting items through the production line. The company's commitment to sustainability and environmental responsibility also sets them apart as a leader in the industry.

Discover the Versatility and Durability of Stainless Steel Profile Wall Paneling

Stainless Steel Profile Wall Paneling Reinvents Modern Interior DesignInnovative interior design solutions are constantly pushing the boundaries of creativity and functionality. Among the latest trends in modern architecture, Stainless Steel Profile Wall Paneling stands as a significant breakthrough, revolutionizing the way we envision interior spaces. With its sleek and contemporary aesthetic, this cutting-edge material has rapidly gained popularity in various residential and commercial projects.Engineered for both durability and style, Stainless Steel Profile Wall Paneling is a versatile design choice that offers numerous advantages over traditional wall coverings. Its unique composition combines the industrial appeal of stainless steel with the clean lines and customizable dimensions of paneling, resulting in a visually striking and functional solution for any interior.One of the many advantages of Stainless Steel Profile Wall Paneling lies in its durability. Stainless steel is known for its corrosion resistance, making it particularly useful in areas with high moisture levels, such as kitchens and bathrooms. Additionally, its resistance to stains, impacts, and scratches ensures a long-lasting and low-maintenance surface. This aspect makes Stainless Steel Profile Wall Paneling ideal for high-traffic areas or spaces prone to wear and tear.Moreover, Stainless Steel Profile Wall Paneling’s unique aesthetic provides a contemporary and sophisticated ambiance to any room. Its sleek and reflective surface adds depth and dimension while effortlessly complementing different design styles. From minimalist to industrial, Stainless Steel Profile Wall Paneling effortlessly enhances the visual appeal of any interior. The ability to choose from various finishes further amplifies its versatility, allowing designers and homeowners to align the material with their desired atmosphere.Installation convenience is another standout feature of Stainless Steel Profile Wall Paneling. The panels are engineered for seamless interlocking, ensuring a hassle-free and time-efficient installation process. This minimizes disruption during construction or renovation projects, making it a preferred choice for both professionals and homeowners seeking efficient design solutions.Given its versatility, Stainless Steel Profile Wall Paneling is suited for both residential and commercial applications. In homes, it can be utilized to create an accent wall, an eye-catching backsplash, or as a unique surface for kitchen cabinets. In commercial spaces, Stainless Steel Profile Wall Paneling serves as an innovative and lasting design choice for hotel lobbies, restaurants, retail stores, and office spaces.As a leader in the field, {} has positioned itself at the forefront of Stainless Steel Profile Wall Paneling innovation. With years of expertise and an expansive range of options, they offer unparalleled quality and service to clients worldwide. Their commitment to excellence is reflected in their meticulous design process and focus on sustainability. By utilizing state-of-the-art technology, they ensure the highest precision and craftsmanship in each panel, resulting in a flawlessly finished product.In conclusion, Stainless Steel Profile Wall Paneling is revolutionizing modern interior design, providing remarkable durability, versatility, and aesthetic appeal. Its sleek and contemporary nature, combined with a range of finishes, allows it to seamlessly integrate into various design styles and applications. As the demand for innovative design solutions continues to grow, Stainless Steel Profile Wall Paneling stands as a testament to the industry's commitment to pushing boundaries and reinventing interior spaces. With {}'s expertise in the field, this pioneering material is set to become an essential element in modern architecture.

Discover the Thrilling Experience of Sightseeing from a Flat Top Base Flight

Flat Top Base Flight: The Ultimate Way to Experience the OutdoorsFlat Top Base Flight, the leading provider of powered paragliding (PPG) equipment and training, is revolutionizing the way outdoor enthusiasts experience the world. By combining the thrill of free-flight with the convenience of a motorized engine, Flat Top Base Flight enables people to soar above breathtaking landscapes with ease and freedom.Founded in 2005 by Jeff Goin, a world-renowned expert in the PPG field, the company has quickly become the go-to source for PPG aficionados. With a deep commitment to safety, quality, and customer satisfaction, Flat Top Base Flight offers a wide range of products and services, including PPG courses, equipment sales and rentals, repairs and maintenance, and online resources.Whether you're a seasoned pilot or a curious beginner, Flat Top Base Flight has something for you. Their flagship product, the Flat Top Ninja, is widely regarded as the best paramotor on the market, thanks to its unparalleled stability, power, and versatility. Designed and manufactured in the USA, the Flat Top Ninja combines cutting-edge technology with years of field testing and customer feedback to deliver the ultimate PPG experience.But Flat Top Base Flight is much more than just a paramotor dealer. Their team of experienced instructors and technicians is dedicated to helping you grow your skills and confidence as a PPG pilot, no matter where you are in your journey. From personalized training programs to ongoing support and mentoring, Flat Top Base Flight is committed to empowering you to explore the world from a new perspective.What sets Flat Top Base Flight apart from other PPG providers is their unwavering focus on safety. Jeff Goin, who has written several books on PPG safety and accident prevention, has made it his mission to promote responsible flying and education within the PPG community. As a result, Flat Top Base Flight has developed a comprehensive safety program that covers everything from equipment selection and maintenance to weather awareness and emergency procedures.Furthermore, Flat Top Base Flight is a strong advocate for environmental conservation and sustainability. They recognize the importance of preserving the natural beauty of our planet and strive to minimize their carbon footprint and environmental impact. In addition, they support various environmental organizations and initiatives that promote conservation and awareness.Whether you're looking to fly over majestic mountains, soar above endless deserts, or glide along the coastline, Flat Top Base Flight has the equipment, expertise, and passion to make it happen. With locations all around the country, including a headquarters in Utah and a training center in Florida, Flat Top Base Flight is accessible to anyone who desires to experience the freedom of flight.In conclusion, Flat Top Base Flight is more than just a PPG company; it's a community of passionate adventurers who share a common love for nature, flight, and exploration. With their innovative products, top-notch training, and unwavering commitment to safety and sustainability, Flat Top Base Flight is leading the way in the world of powered paragliding.

Top Speed Record Shattered: Electric Vehicle Breaks Barriers with Remarkable Agility

[Publication Name] - [Publication Date][Headline]Electric Vehicle Pioneer to Revolutionize Transportation: [Company Name]'s Game-Changing Solution[Subtitle]The Future of Transportation is Here: A Revolutionary Breakthrough to Tackle Global Emissions[Location], [Date] - Today, a groundbreaking and eco-friendly solution has been announced by [Company Name], revolutionizing the way we think about transportation. This game-changing innovation seeks to combat the world's growing carbon emissions problem, setting a new standard in sustainable and efficient mobility.[Company Name], a leader in electric vehicle technology, aims to provide a viable alternative to traditional gasoline-powered cars and set a benchmark for environmental responsibility. With a relentless commitment to sustainability, the company has been working diligently to develop their latest brainchild – a cutting-edge vehicle known as the Bolt.[Company Name]'s Bolt, an electric vehicle like no other, is set to spearhead the company's mission toward a greener future. By combining seamless design with innovative technology, the Bolt boasts an unrivaled driving experience while remaining environmentally conscious. Let's delve into the key features that make this vehicle a true game-changer.[Subtitle]Revolutionary Design: Aesthetics Meets FunctionalityWith sleek lines, bold curves, and a streamlined profile, the Bolt truly redefines contemporary automotive design. The vehicle's ergonomic interior ensures comfort, while its state-of-the-art infotainment system guarantees an immersive driving experience. This innovative design, combined with cutting-edge engineering, showcases [Company Name]'s unwavering commitment to creating a truly magnificent vehicle.[Subtitle]Electrified Performance: A Thrilling Experience with Zero EmissionsThe Bolt's electric engine is a technological marvel, providing exceptional power and efficiency. Its instant torque delivers electrifying acceleration, transforming driving into an exhilarating experience. Zero tailpipe emissions mean cleaner air for all, as [Company Name] aims to lessen the environmental impact of transportation and promote a greener society.[Subtitle]Battery Breakthrough: Unraveling the Potential of Electric MobilityOne of the most significant advancements in the Bolt is its groundbreaking battery technology. Through years of intensive research and development, [Company Name] has created an advanced battery pack that maximizes range and minimizes charging time. With this game-changing breakthrough, the Bolt can travel longer distances on a single charge while drastically reducing the time spent charging.[Subtitle]Infrastructure Expansion: Paving the Way for Widespread Adoption[Company Name] recognizes the importance of developing a robust infrastructure to support the widespread use of electric vehicles. As part of their commitment to facilitating the transition to sustainable transportation, the company has invested heavily in charging stations, both domestically and globally. This infrastructure expansion will help eliminate range anxiety and ensure that the Bolt and other electric vehicles are practical options for everyone, regardless of location.[Subtitle]Global Impact: Transforming Transportation for a Sustainable FutureThe revolutionary Bolt not only offers cutting-edge technology and exhilarating performance but also represents a significant step forward in fighting climate change. By reducing carbon dioxide emissions and advocating for sustainable transportation, [Company Name] aims to be at the forefront of the green revolution. The company's dedication to the cause has garnered worldwide attention, with governments, environmentalists, and consumers recognizing [Company Name]'s commitment to a sustainable future.[Subtitle]ConclusionWith the introduction of the Bolt, [Company Name] has positioned itself as a dominant force in the electric vehicle industry. Offering a unique combination of stunning design, electrifying performance, and a genuine commitment to sustainability, the Bolt is set to change the trajectory of transportation and serve as an inspiration to industries worldwide. As we move toward a sustainable future, [Company Name] paves the way for a greener, cleaner, and more environmentally responsible tomorrow.[Contact Information]For media inquiries, please contact:[Company Name][Phone Number][Email Address][Website][Twitter Handle][Facebook Page]

Discover the Latest Trends in Steel Cladding Profiles for Enhanced Aesthetics and Durability

[Your Name][Your Title][Date][News Outlet Name / Website]Headline: Steel Cladding Profiles: A New Era of Innovation and Sustainability in ConstructionIntroduction:In an era where construction projects are evolving rapidly, the demand for high-quality building materials is at an all-time high. One company leading the charge in this sector is Steel Cladding Profiles (SCP), a globally renowned manufacturer of cutting-edge steel cladding products. SCP's commitment to innovation, sustainability, and customer satisfaction have made them a go-to choice for architects, builders, and developers worldwide.Body:1. Introduction to Steel Cladding Profiles:Steel Cladding Profiles (SCP) has been an industry leader in the manufacturing of steel cladding products for over two decades. Headquartered in [Headquarters Location], SCP has steadily expanded its operations globally, catering to a diverse array of construction projects, including commercial buildings, residential complexes, and industrial facilities. The company's core principles revolve around quality, sustainability, and customer-centricity.2. Innovation in Steel Cladding:SCP's dedication to innovation has positioned them as pioneers in the field of steel cladding. Their state-of-the-art research and development facility is constantly exploring new techniques and materials to enhance the strength, durability, and aesthetic appeal of their products. SCP's team of skilled engineers and designers collaborate closely with clients to customize cladding solutions that meet their specific requirements, often surpassing industry standards.3. Sustainability at the Heart of SCP's Operations:In an era where environmental consciousness is paramount, SCP's commitment to sustainability sets them apart. The company employs advanced manufacturing processes that minimize energy consumption and waste generation. Moreover, SCP's steel cladding profiles are often made from recycled materials, reducing the need for virgin resources. By offering sustainable solutions without compromising quality or performance, SCP helps construction projects contribute to a greener, more sustainable future.4. Product Portfolio:SCP offers a diverse range of steel cladding profiles that cater to various architectural styles and project needs. Their product portfolio includes the following:- Ribbed Profiles: SCP's ribbed profiles provide superior architectural aesthetics while enhancing structural stability. These profiles are ideal for commercial and residential buildings seeking a modern and sleek appearance.- Corrugated Profiles: SCP's corrugated profiles offer both strength and flexibility, making them suitable for large-span constructions. These profiles ensure water-tightness and are often used in industrial complexes and warehouses.- Standing Seam Profiles: SCP's standing seam profiles are renowned for their weather resistance and longevity. With concealed fasteners and a distinctive raised seam, these profiles are perfect for roofing applications in both residential and commercial projects.- Insulated Panels: SCP's insulated panels combine superior insulation properties with appealing aesthetics. These panels are an ideal choice for energy-efficient constructions, promoting reduced heating and cooling costs.5. Global Reach and Success Stories:SCP's dedication to quality and customer satisfaction has enabled them to establish a global footprint. From large-scale infrastructure projects to architectural marvels, SCP's steel cladding profiles have been used in projects across the world. Notable success stories include the iconic [Name of Project], which showcases the company's commitment to excellence and innovation.Conclusion:Steel Cladding Profiles (SCP) has emerged as a leading manufacturer of steel cladding products, setting new industry standards in innovation, sustainability, and customer satisfaction. SCP's diverse product portfolio, commitment to quality, and global reach make them the preferred choice for architects, builders, and developers looking for high-performance cladding solutions. With SCP, construction projects can embrace a new era of innovation and sustainability, ushering in a brighter future for the industry as a whole.[Word Count: 654]

Discover the Beauty of Flat Top Base Aerial Adventure in Colorado

Title: Helicopter Airbase Unveils Cutting-Edge Flat Top Base Flight SystemIntroduction: In a groundbreaking achievement for the aviation industry, a leading helicopter airbase has recently unveiled its latest innovation - the cutting-edge Flat Top Base Flight system. Designed to revolutionize the capabilities and efficiency of helicopter operations, this advanced technology aims to transform the way helicopters take off and land, ultimately enhancing safety measures and ensuring a smoother and more reliable experience for pilots and passengers alike.I. The Flat Top Base Flight System: A Game-Changing InnovationThe Flat Top Base Flight system is a state-of-the-art technology developed by the industry-leading aviation company {}. This revolutionary system is unlike any other existing platform and promises to redefine the conventional helicopter landing experience. Unlike traditional helipads, which are often limited by space and design constraints, this innovative system features a completely flat surface specifically engineered to enable helicopter take-offs and landings. By eliminating the need for sloped landings, this unique technology opens up new possibilities for airbases and provides significant advantages for operators and pilots.One standout feature of this groundbreaking system is its ability to accommodate various types and sizes of helicopters. Thanks to its adjustable and adaptable nature, the Flat Top Base Flight system can cater to a diverse range of rotorcraft, from small helicopters to larger military-grade aircraft. This versatility will help airbases broaden their operations and cater to a wider range of aerial missions.II. Enhanced Safety Measures and Operational EfficiencyWith safety as a top priority, the Flat Top Base Flight system incorporates several advanced features to ensure a secure and reliable landing experience for helicopter pilots. The level surface eliminates any potential trip hazards and reduced slopes, reducing the risk of accidents during take-off and landing. Additionally, the system is equipped with specialized lighting to enhance visibility during nighttime operations, further improving safety standards.Incorporating this cutting-edge system into helicopter airbases not only enhances safety measures but also enhances operational efficiency. The Flat Top Base Flight system minimizes downtime between landings and take-offs, allowing for a smoother flow of operations. By reducing turnaround times, airbases can maximize their capacity, increase flight frequency, and meet the growing demand for efficient helicopter services.III. Environmental Impact and SustainabilityThe Flat Top Base Flight system also prioritizes environmental sustainability. By implementing this innovative technology, helicopter airbases can mitigate the environmental impact typically associated with conventional helipads. The system utilizes reusable materials that reduce waste production and has a smaller carbon footprint. In addition, the increased operational efficiency resulting from reduced turnarounds translates into lower fuel consumption, ultimately contributing to a greener aviation industry.IV. Real-World Applications and Future PotentialThe implementation of the Flat Top Base Flight system holds tremendous potential for a range of industries dependent on helicopter operations. From emergency medical services to military operations, this innovation promises to enhance the effectiveness and safety of various missions. Additionally, the technology's adaptability allows for the establishment of temporary landing sites in remote or challenging locations, further expanding its potential applications.Moreover, this groundbreaking system sets a strong foundation for future advancements in the aviation industry. With ongoing research and development, airbases can continue to refine and optimize the Flat Top Base Flight system, ensuring its long-term viability and further unlocking its potential.Conclusion:The introduction of the Flat Top Base Flight system marks a significant milestone in the aviation industry. By revolutionizing the way helicopters take off and land, this cutting-edge technology enhances safety measures, improves operational efficiency, and promotes environmental sustainability. With its versatility and adaptability, airbases equipped with the Flat Top Base Flight system are poised to meet the ever-increasing demands of diverse missions and pave the way for the future of helicopter operations.

How to Weld Square Tubing End to End: A Step-by-Step Guide

Title: Welding Square Tubing End To End: A Prominent Solution for Seamless ConnectionsIntroduction:Welding square tubing end to end has emerged as a popular technique across various industries, enabling seamless and robust connections between tubes. This highly versatile method has revolutionized the manufacturing and construction sectors, allowing for greater structural integrity, superior performance, and enhanced aesthetics. Several companies have become leaders in this field, striving to provide innovative solutions for joining square tubing in a reliable, efficient, and cost-effective manner.Company Introduction:With a strong focus on delivering cutting-edge welding solutions, [Company Name] has made significant strides in the industry. Recognized for its commitment to excellence, the company has established a reputation for providing high-quality products, outstanding customer service, and unparalleled expertise. Employing a team of experienced professionals and leveraging advanced technologies, [Company Name] has become a trusted partner for various businesses seeking welding solutions for their square tubing requirements.News Content:1. Importance of Welding Square Tubing End To End:Joining square tubing end to end through welding plays a crucial role in several industries, including construction, manufacturing, and infrastructure development. This technique ensures the creation of continuous, sturdy connections that are capable of withstanding heavy loads, vibrations, and environmental factors. Welded square tubing effectively eliminates the need for bulky connectors or additional support, resulting in improved aesthetics and versatile design possibilities.2. Advantages of Welding Square Tubing End To End:By selecting the appropriate welding method and using state-of-the-art equipment, companies like [Company Name] can offer numerous benefits associated with welding square tubing end to end. These advantages include:a) Seamless Integration: Welding ensures a seamless integration of square tubes, where the joint area is just as strong as the rest of the material, eliminating weak points.b) Enhanced Structural Integrity: The welded joint provides superior strength and durability, making it suitable for applications that require high structural integrity and load-bearing capabilities.c) Efficient and Cost-Effective: Welding square tubing end to end is a rapid and efficient process that reduces the time and cost associated with assembly. It eliminates the need for additional connectors or fasteners, streamlining production and minimizing expenses.d) Aesthetic Appeal: Due to its ability to create flush connections, welded square tubing end to end results in clean, visually appealing finishes, making it an ideal choice for architectural and decorative applications.3. [Company Name] Revolutionizes the Square Tubing Welding Industry:[Company Name] has taken a pioneering role in the development and improvement of welding techniques for square tubing. Its continuous research and development efforts have led to the introduction of advanced welding processes, ensuring optimal performance in various applications.a) Cutting-edge Technologies: By utilizing state-of-the-art welding equipment, [Company Name] maintains the highest standards of quality and precision in the welding process. Advanced technologies allow for increased efficiency, reduced defects, and exceptional craftsmanship.b) Tailored Solutions: [Company Name] understands that each customer's needs are unique, and therefore, offers customized welding solutions that meet specific project requirements. This includes welding square tubing of different sizes, thicknesses, and materials to cater to diverse industry demands.c) Collaborative Approach: [Company Name] values collaboration and works closely with clients to gain a comprehensive understanding of their welding needs. This approach enables the company to provide tailor-made solutions that fulfill the desired outcome, ensuring customer satisfaction.Conclusion:The technique of welding square tubing end to end has proven to be a game-changer in the manufacturing and construction sectors. Through this method, superior structural integrity, enhanced aesthetics, and efficient assembly processes are achieved. [Company Name], with its commitment to excellence, cutting-edge technologies, and customized solutions, emerges as a leading provider of welding services, revolutionizing the square tubing welding industry.