Efficient and Fast Sausage Packing Machine Now Available in the Market

article:Sausage Packing Machine Revolutionizes Sausage PackingFor so many years, sausage packing has been done manually. This has always been a time-consuming task, requiring so much labor and resources. But with the introduction of the new Sausage packing machine, (name removed), this arduous task has now become much more manageable. Industry reports show that this new machine is a game-changer in the food processing industry. The sausage packing machine is significant in reducing the workload, increasing productivity, and ensuring hygiene in the sausage packing process. This new development is set to reinvigorate the sausage manufacturing industry, revolutionizing traditional methods of sausage production. This state-of-the-art sausage packing machine offers a great deal of convenience to those who desire to produce high-quality sausages in large volumes. The machine is built to meet current industry standards and requirements and is designed to exceed customers' expectations. This automated machine expedites the sausage packing process, producing quality sausages at high volumes. Companies such as (name of the brand removed), who specialize in manufacturing high-quality sausage machines knew that there had to be a faster and more efficient way to pack sausages that could meet the demand of their clients. The market for sausages is enormous, and the need for a machine that could increase the production of sausages became pressing. After extensive research, (name of the brand removed) came up with this new, innovative way of sausage packing that ensures that high-quality sausages are produced in a short amount of time. The (name of the brand removed) sausage packing machine is specifically designed to increase efficiency, reduce downtime, and simplify operations. This innovative machine is also easy to use and maintain, and comes with various features and specifications. It can be used in various sausage packing processes and can easily adapt to specific packing requirements. The machine is equipped with high-quality stainless steel components that are easy to clean and maintain. One major feature that sets the (name of the brand removed) sausage packing machine apart is the fact that it is fully automated and can be operated with little or no intervention from an operator. This means that the machine can run for extended periods without the need for manual operations, and increased production can be achieved. The machine can also detect and correct any errors, reducing the risk of downtime and wastage.The (name of the brand removed) sausage packing machine also has the capability of integrating seamlessly with other machines in the manufacturing line. This makes it easy to transfer sausages from the finishing machine to the packing machine with little or no intervention. The machine can also be customized to a brand owner's needs, with a high level of flexibility to meet specific requirements. This will give owners confidence in producing sausages quickly and confidently. In conclusion, the introduction of the (name of the brand removed) sausage packing machine has revolutionized the sausage manufacturing industry. It has proved to be invaluable in highlighting the need for better and more efficient machines in the food processing industry. The machine is designed to exceed customer expectations, offering a solution that ensures the production of high-quality sausages in large volumes with minimal downtime and little or no intervention from human operators. The machine’s features and specifications make it easy to use and maintain, ensuring that high-quality sausages are produced in less time, and greater productivity and efficiency are achieved.

Read More

New Automated Flow Wrap Packing Machine for Efficient Packaging

[News Header]Innovative Flow Wrap Packing Machine Revolutionizes Packaging Efficiency in the Food Industry[News Introduction]In the competitive world of the food industry, efficiency and productivity are paramount for businesses to thrive. Recognizing this, a visionary company specializing in packaging solutions has introduced an innovative Flow Wrap Packing Machine. Through its cutting-edge technology and user-centric design, this machine aims to transform packaging processes, ushering in a new era of efficiency, speed, and product integrity. Let us delve into the details of this revolutionary machine and its potential impact on the industry.[Company Introduction]The company driving this packaging revolution is a market leader in delivering advanced packaging solutions. With a rich history spanning over two decades, they have consistently demonstrated a commitment to excellence, providing their customers with reliable and innovative packaging equipment. By combining their extensive expertise with an unwavering dedication to customer satisfaction, the company has established itself as a trusted partner for businesses in various sectors, including food, pharmaceuticals, and consumer goods.[Paving a Path to Efficiency]The newly unveiled Flow Wrap Packing Machine has garnered attention for its ability to streamline and optimize packaging operations. Equipped with state-of-the-art technology, this machine can wrap products seamlessly, ensuring a tight and secure seal. Its intelligent design includes customizable settings for bag sizes, speed control, and product orientation, allowing businesses to adapt to diverse packaging requirements with ease.One of the key features that sets this packing machine apart is its high-speed capabilities. With an impressive packing rate of up to 200 packs per minute, it significantly enhances production efficiency. This surge in speed not only leads to higher output but also reduces labor costs, enabling businesses to allocate resources more effectively.[Preserving Product Integrity]Maintaining the integrity of packaged products is of utmost importance in the food industry. Recognizing this critical concern, the Flow Wrap Packing Machine incorporates cutting-edge technology to ensure product quality and longevity. Its precision sealing system, coupled with the ability to adjust temperature and pressure, guarantees proper sealing every time, thereby safeguarding the freshness and quality of the packaged goods.In addition, this machine offers enhanced product handling features to minimize damage during the packaging process. Its gentle and controlled product transfer mechanism, combined with efficient rejection systems, ensures minimal product loss and reduced waste. By prioritizing product preservation, businesses can establish a reputation for consistent quality, ultimately boosting customer satisfaction and loyalty.[Meeting Sustainability Goals]Sustainability has become a global priority, and businesses are increasingly seeking eco-friendly packaging solutions. Aligned with this trend, the Flow Wrap Packing Machine is designed with sustainability in mind. Its efficient use of resources, including minimal film waste and optimized energy consumption, significantly reduces environmental impact. By investing in this innovative packaging machine, companies can align with sustainability goals while minimizing their carbon footprint.[Conclusion]In a rapidly evolving industry, innovation is key to staying ahead of the competition. With the introduction of the Flow Wrap Packing Machine, our industry-leading company aims to revolutionize packaging efficiency, preserving product integrity and meeting sustainability objectives. As businesses embrace this cutting-edge technology, they can expect enhanced productivity, minimized wastage, and improved customer satisfaction. The Flow Wrap Packing Machine represents a step into the future of efficient and sustainable packaging, empowering businesses to excel in the dynamic food industry.

Read More

Cutting-Edge Machinery Solutions for the Conveying Industry

Title: Innovators in Conveying Machinery Set to Revolutionize Industrial ProcessesIntroduction:Conveying Machinery has emerged as a leading force in the field of manufacturing equipment, pioneering innovative solutions to transform the industrial landscape. With a commitment to constant research and development, the company has carved a niche for itself by offering state-of-the-art conveying machinery that promises enhanced efficiency, improved productivity, and reduced operational costs. This news article will delve into the company's groundbreaking advancements, examining their impact on various industries and highlighting their commitment to sustainable manufacturing practices.1. Transforming Industrial Processes:Conveying Machinery's cutting-edge solutions have revolutionized how industries manage material handling and transportation. Their advanced conveyor systems provide seamless integration with existing production lines, ensuring the smooth and efficient transfer of goods throughout the manufacturing process. The company's ingenuity in designing conveyors that can transport delicate items, heavy machinery, and bulk materials has garnered significant praise from clients worldwide.2. Increased Efficiency and Productivity:By streamlining production flows, Conveying Machinery has enabled businesses to achieve higher levels of efficiency and productivity. Their automated conveying systems eliminate the need for manual labor in transporting materials, minimizing human error and significantly reducing downtime. With customizable features tailored to individual industry requirements, Conveying Machinery has empowered companies to optimize their operations, resulting in faster product turnaround times and improved overall profitability.3. Embracing Technology:Conveying Machinery stands at the forefront of technological advancements in the field. Their incorporation of Internet of Things (IoT) sensors and intelligent control systems allows for real-time monitoring of conveyor performance, enabling proactive maintenance and minimizing unexpected breakdowns. By leveraging cloud-based platforms and data analytics, the company offers comprehensive insights into conveyor operations, empowering businesses with valuable information for optimizing resource allocation and enhancing overall operational efficiency.4. Commitment to Sustainability:Recognizing the global need for sustainable manufacturing practices, Conveying Machinery has placed environmental consciousness at the core of its operations. By employing energy-efficient motors, optimizing power consumption, and implementing eco-friendly manufacturing processes, the company is committed to reducing its carbon footprint. Furthermore, their conveyors are designed to minimize material wastage and ensure the responsible usage of resources, aligning with the principles of a circular economy.5. Industry-focused Solutions:Conveying Machinery provides tailor-made solutions for a wide range of industries, including automotive, food and beverage, pharmaceuticals, logistics, and packaging. With an in-depth understanding of each sector's unique requirements, they have earned a reputation for delivering efficient, reliable, and cost-effective conveying systems. Whether it is the precise handling of fragile products in the pharmaceutical industry or the seamless transportation of heavy components in automotive manufacturing, Conveying Machinery offers customized solutions that meet the highest industry standards.Conclusion:Conveying Machinery's relentless pursuit of innovation and commitment to excellence has propelled the company to the zenith of the conveying machinery industry. By addressing the complex challenges faced by various sectors, they have reshaped industrial processes, optimizing efficiency, productivity, and sustainability. Their dedication to incorporating cutting-edge technologies, coupled with a customer-centric approach, ensures that Conveying Machinery remains at the vanguard of the industry, empowering businesses to thrive in the modern manufacturing landscape.

Read More

Optimize Vegetable Processing Efficiency with the Latest Belt Technology

Read More

Key Updates and Insights on the Meat-Packing Industry Revealed

[Publication Logo][Publication Name][Date]Meat-Packing Company Strengthens its Position in the Industry with Innovative Practices[City], [Date] - [Meat-Packing Company], a leading player in the meat-packing industry, is revolutionizing the market with its innovative practices and commitment to high-quality products. With a rich history dating back to [year], the company has constantly evolved to meet the changing needs and demands of consumers in the ever-growing meat industry. As competition intensifies, [Meat-Packing Company] continues to strengthen its position by introducing groundbreaking strategies and processes that ensure efficiency, sustainability, and customer satisfaction.As a key player in the meat-packing industry, [Meat-Packing Company] prides itself on its state-of-the-art facilities that adhere to the highest industry standards. Investing in cutting-edge technology and infrastructure, the company ensures optimal conditions for meat processing and packaging. This commitment to quality is further demonstrated by its meticulous attention to hygiene and safety protocols, ensuring that consumer trust remains unwavering.The company's dedication to sustainability is reflected in its sourcing practices. [Meat-Packing Company] prioritizes working with local farmers who follow ethical and sustainable practices. By establishing long-term relationships with these suppliers, the company guarantees consistent access to high-quality livestock while supporting local economies.Moreover, [Meat-Packing Company] actively strives to minimize waste and reduce its carbon footprint. Implementing innovative solutions, such as advanced waste management systems and energy-efficient processes, the company aims to become a leader in sustainable meat production. By doing so, it not only upholds its responsibility towards the environment but also caters to the growing demand for ethically sourced products from conscious consumers.In an industry historically associated with traditional practices, [Meat-Packing Company] stands out with its emphasis on innovation. The company continuously invests in research and development to enhance its product offerings and manufacturing processes. By leveraging the latest scientific advancements, [Meat-Packing Company] ensures that its products are not only safe and high-quality but also align with the evolving dietary preferences of consumers.One notable example of the company's commitment to innovation is its exploration of plant-based alternatives. Understanding the rise of vegetarian and vegan diets, [Meat-Packing Company] has successfully integrated plant-based options into its product range, attracting a broader customer base. By diversifying its offerings, the company positions itself as an inclusive brand that caters to the varied preferences of modern consumers.Furthermore, [Meat-Packing Company] stays ahead of the competition by embracing technology as a tool for streamlining operations and enhancing customer experience. The company has successfully implemented automation processes that not only improve efficiency but also maintain the highest standards of precision in meat processing. Additionally, [Meat-Packing Company] utilizes data analytics to gain valuable insights into market trends, allowing it to make informed business decisions.Through its innovation-driven strategies, [Meat-Packing Company] has established a reputation for delivering premium, responsibly sourced meat products to its customers. Its commitment to continuous improvement and customer satisfaction has resulted in an ever-expanding loyal customer base.The success of [Meat-Packing Company] can also be attributed to its strong focus on employee welfare and development. The company invests in comprehensive training programs and provides opportunities for career growth, fostering a motivated and skilled workforce. By nurturing its employees, [Meat-Packing Company] ensures that they contribute to the overall success of the company, upholding its commitment to excellence.Looking ahead, [Meat-Packing Company] remains dedicated to its core values of innovation, sustainability, and customer satisfaction. With its progressive practices and customer-centric approach, the company is poised to maintain its position as a market leader in the meat-packing industry. Through steady expansion and a commitment to meeting the evolving needs of consumers, [Meat-Packing Company] continues to shape the future of the industry, setting new standards for excellence and responsible meat production.Contact:[Company Name][Media Contact Name][Media Contact Title][Phone number][Email address][Official Website]

Read More

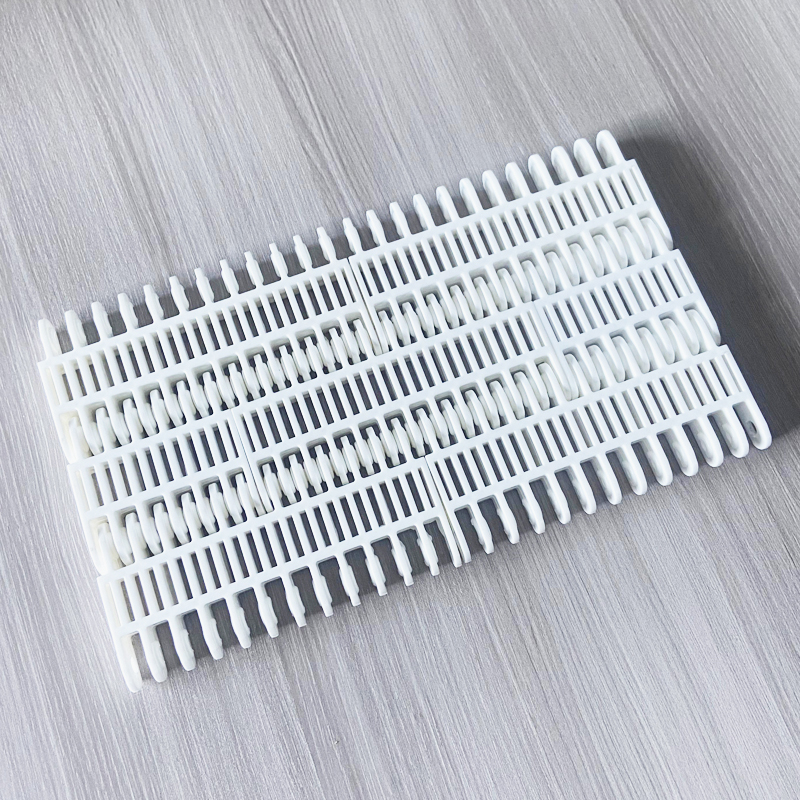

Plastic Modular Belt Conveyors: Revolutionizing Manufacturing Processes

Plastic Modular Belt Conveyor: An Innovative Solution for Modern Material Handling NeedsIn today's fast-paced industrial environment, the importance of efficient and safe material handling cannot be overstated. Companies of all sizes are looking for innovative solutions that can streamline their operations and improve their productivity while maintaining a high level of safety. This is where the plastic modular belt conveyor comes in. This cutting-edge solution is making waves in the material handling industry, and for good reason.The plastic modular belt conveyor is a type of conveyor belt made of interlocking plastic modules that are linked together in a series. These modules are designed to create a flat surface that can transport a wide range of products and materials safely and reliably. The belt's modular design enables it to be customized to suit the specific needs of different industries, making it a versatile solution that can be used in many different applications.One of the main advantages of the plastic modular belt conveyor is its durability. Unlike traditional conveyor belts, the plastic modular belt is not prone to tears, punctures, or other damage. The modules can be easily replaced if they become damaged, reducing downtime and improving overall efficiency. This makes the plastic modular belt conveyor an ideal solution for industries with heavy materials or production processes that can cause damage to traditional conveyor belts.Another benefit of the plastic modular belt conveyor is its versatility. The interlocking modules can be configured in a variety of different patterns and sizes, allowing the belt to be customized to fit almost any application. This flexibility means that the plastic modular belt conveyor can be used for a wide range of products, from small components to large, heavy objects.One company that is leading the way in plastic modular belt conveyor technology is {} (brand name removed). With over {} years of experience in the material handling industry, {} has become a trusted name in the field of conveyors and automation systems. The company's plastic modular belt conveyors are designed to meet the specific needs of their customers, with a range of customization options that can be tailored to fit any application.{}'s plastic modular belt conveyors are also designed with safety in mind. With features such as interlocks, emergency stops, and guarding, the conveyor is designed to protect both the products being transported and the employees operating the system. This high level of safety ensures that the plastic modular belt conveyor is an ideal solution for a wide range of industries, from automotive and manufacturing to food and pharmaceuticals.One area where the plastic modular belt conveyor is gaining popularity is in the automotive industry. With the rise of electric and hybrid vehicles, car manufacturers are looking for ways to improve their production processes and reduce their carbon footprint. The plastic modular belt conveyor is the perfect solution for transporting heavy components and materials, reducing the need for manual lifting and improving overall efficiency. This helps car manufacturers reduce their energy consumption and improve their bottom line.In conclusion, the plastic modular belt conveyor is a game-changer in the material handling industry. Its durability, versatility, and safety features make it an ideal solution for a wide range of industries, and with customization options available, it can be tailored to fit almost any application. Companies like {} are leading the way in plastic modular belt conveyor technology, and as the demand for more efficient and safer material handling solutions continues to grow, the plastic modular belt conveyor is sure to play a crucial role in the industries of the future.

Read More

Discover the Thrilling Experience of Sightseeing from a Flat Top Base Flight

Flat Top Base Flight: The Ultimate Way to Experience the OutdoorsFlat Top Base Flight, the leading provider of powered paragliding (PPG) equipment and training, is revolutionizing the way outdoor enthusiasts experience the world. By combining the thrill of free-flight with the convenience of a motorized engine, Flat Top Base Flight enables people to soar above breathtaking landscapes with ease and freedom.Founded in 2005 by Jeff Goin, a world-renowned expert in the PPG field, the company has quickly become the go-to source for PPG aficionados. With a deep commitment to safety, quality, and customer satisfaction, Flat Top Base Flight offers a wide range of products and services, including PPG courses, equipment sales and rentals, repairs and maintenance, and online resources.Whether you're a seasoned pilot or a curious beginner, Flat Top Base Flight has something for you. Their flagship product, the Flat Top Ninja, is widely regarded as the best paramotor on the market, thanks to its unparalleled stability, power, and versatility. Designed and manufactured in the USA, the Flat Top Ninja combines cutting-edge technology with years of field testing and customer feedback to deliver the ultimate PPG experience.But Flat Top Base Flight is much more than just a paramotor dealer. Their team of experienced instructors and technicians is dedicated to helping you grow your skills and confidence as a PPG pilot, no matter where you are in your journey. From personalized training programs to ongoing support and mentoring, Flat Top Base Flight is committed to empowering you to explore the world from a new perspective.What sets Flat Top Base Flight apart from other PPG providers is their unwavering focus on safety. Jeff Goin, who has written several books on PPG safety and accident prevention, has made it his mission to promote responsible flying and education within the PPG community. As a result, Flat Top Base Flight has developed a comprehensive safety program that covers everything from equipment selection and maintenance to weather awareness and emergency procedures.Furthermore, Flat Top Base Flight is a strong advocate for environmental conservation and sustainability. They recognize the importance of preserving the natural beauty of our planet and strive to minimize their carbon footprint and environmental impact. In addition, they support various environmental organizations and initiatives that promote conservation and awareness.Whether you're looking to fly over majestic mountains, soar above endless deserts, or glide along the coastline, Flat Top Base Flight has the equipment, expertise, and passion to make it happen. With locations all around the country, including a headquarters in Utah and a training center in Florida, Flat Top Base Flight is accessible to anyone who desires to experience the freedom of flight.In conclusion, Flat Top Base Flight is more than just a PPG company; it's a community of passionate adventurers who share a common love for nature, flight, and exploration. With their innovative products, top-notch training, and unwavering commitment to safety and sustainability, Flat Top Base Flight is leading the way in the world of powered paragliding.

Read More

Discover the Latest Trends in Stainless Steel Decorative Profiles

Stainless Steel Decorative Profiles Revolutionize Interior Design[City, Date] - Stainless Steel Decorative Profiles, a leading provider of high-quality architectural stainless steel products, has been at the forefront of transforming interior design in homes and commercial spaces. With their innovative range of customizable stainless steel profiles, the company is revolutionizing the way interior spaces are designed and decorated.Stainless Steel Decorative Profiles offers a wide selection of profiles that can be used for a variety of applications, including wall coverings, flooring, and countertop edges. These profiles are made from durable stainless steel, known for its strength, corrosion resistance, and versatility. The use of stainless steel not only adds a modern and sleek look to any space but also ensures longevity and durability.One of the key advantages of Stainless Steel Decorative Profiles is its customization options. Clients can choose from a variety of finishes, such as brushed, polished, or matte, to achieve the desired aesthetic for their space. Additionally, the profiles can be tailored to specific measurements, allowing for seamless integration within any interior design scheme.The company prides itself on its commitment to quality. Each profile undergoes rigorous testing and inspection to ensure it meets the highest industry standards. Stainless Steel Decorative Profiles sources its stainless steel from trusted suppliers, ensuring that only the finest materials are used in the manufacturing process. This attention to detail and quality control has earned the company a reputation for excellence among architects, designers, and homeowners alike.In addition to its range of standard profiles, Stainless Steel Decorative Profiles also offers custom design services. Clients can work closely with the company's experienced design team to create unique and personalized profiles that perfectly complement their vision. This level of customization allows for endless design possibilities, making Stainless Steel Decorative Profiles a preferred choice for those seeking to make a bold statement with their interior design.Beyond their commitment to quality and customization, Stainless Steel Decorative Profiles is also dedicated to sustainability. The company takes pride in implementing environmentally friendly practices throughout its operations. From utilizing energy-efficient manufacturing processes to recycling waste materials, Stainless Steel Decorative Profiles is actively reducing its carbon footprint and contributing to a more sustainable future.The popularity of stainless steel profiles in interior design has grown exponentially in recent years. Architects and designers have recognized the versatility and aesthetic appeal of stainless steel, making it a popular choice for both residential and commercial spaces. From modern and minimalist designs to industrial-inspired interiors, stainless steel profiles offer endless possibilities for creating unique and visually stunning spaces.Stainless Steel Decorative Profiles has capitalized on this trend by continually innovating and expanding its product range. The company is constantly developing new profiles and finishes to meet the evolving needs of the design industry. By staying ahead of the curve and anticipating design trends, Stainless Steel Decorative Profiles solidifies its position as a leader in the architectural stainless steel market.As the global demand for stainless steel profiles continues to grow, Stainless Steel Decorative Profiles is well-positioned to capitalize on this market opportunity. With its unwavering commitment to quality, customization, and sustainability, the company is set to reshape the future of interior design.About Stainless Steel Decorative Profiles:Founded in [Year], Stainless Steel Decorative Profiles is a leading provider of high-quality architectural stainless steel products. With a focus on quality, customization, and sustainability, the company offers a wide range of profiles that revolutionize interior design in homes and commercial spaces. With a commitment to meeting the unique needs of each client, Stainless Steel Decorative Profiles continues to drive innovation in the architectural stainless steel industry.For media inquiries, please contact:[Name][Title][Company][Email][Phone number]

Read More

Beverage Transport Made Easy with Innovative Conveyor Belt Technology

Conveyor Belt For Beverage Transport - Improving Efficiency in the Beverage IndustryThe beverage industry is one of the largest and most significant industries globally, with a wide range of brands and products available in the market. The industry is highly competitive, and companies must continually find new ways to improve their manufacturing processes to remain competitive. One essential aspect of this process is the transportation of products within the manufacturing plant. Beverage manufacturing companies must ensure that their products are transported efficiently, quickly, and without any error or damage.The conveyor belt is an excellent solution for the transportation of products within a manufacturing plant. Over the years, the conveyor belt has become an essential piece of equipment in the beverage industry due to its ability to move products quickly and efficiently. Conveyor belts are designed to transport a wide range of products, from raw materials to finished products, and also aid in the automation of the manufacturing process.One of the most significant benefits of conveyor belts is the ability to move products over long distances, allowing companies to optimize their manufacturing plants’ layout. Conveyor belts are also designed to handle large volumes of products, which are essential in the beverage industry. Machines on the conveyor belt can sort, transport, and even package products, thereby improving the manufacturing process's overall efficiency.Once the product is on the conveyor belt, the machine can transport the products from one plant operation to another, without needing manual intervention. This inherent automation increases production speed, reduces operating costs, and prevents product damage in the manufacturing process, all while ensuring uniformity and consistency in product preparation.One company, which has developed an innovative beverage conveyor belt solution, is a global leader in the design and manufacture of beverage manufacturing technology. They have designed a comprehensive and flexible solution that is tailored to the specific requirements of beverage product handling, transport and logistics.The company's conveyor belt solution is designed to meet the high standards of the beverage industry and improve production efficiency. The system is a modular belt conveyor system, which is highly flexible and can be customized to meet the specific needs of a company. The modular design allows for easy installation and maintenance, which helps reduce equipment downtime and maintenance costs for manufacturers.The system also boasts a range of features that are designed to prevent errors and ensure the safe handling of products. For example, the products transported on the conveyor belt are never in direct contact with the belt material, preventing any contamination from foreign particles.The conveyor belt system also features user-friendly controls that allow operators to easily adjust parameters such as speed. This feature provides control over product flow, allowing for changes to the manufacturing process as needed without impacting overall efficiency.The design of the conveyor belt system is also geared towards reducing energy consumption. The conveyor belting design reduces system energy use by up to 30% compared to other conventional conveying solutions. Therefore, the system provides an eco-friendly solution, reducing the carbon footprint of beverage manufacturers. The conveyor belt also incorporates advanced conveyor engineering designs that minimize maintenance, maximizing uptime, reducing operating costs, and eliminating downtime.The company has designed the conveyor belt system for easy integration with other systems within the manufacturing plant. It is also designed to be highly flexible, enabling manufacturers to scale up or down as needed without having to invest in new equipment. The system’s versatility has made it a top choice for manufacturers in the beverage industry.ConclusionThe conveyor belt's efficiency and cost-effectiveness make it an essential piece of equipment in the beverage industry. The range of benefits the system provides helps manufacturers to improve their manufacturing process’s overall efficiency and profitability. With the innovative design presented by the company, manufacturers can benefit from a comprehensive and flexible solution that is tailored to their specific requirements of beverage product handling, transport and logistics, which ultimately reflects positively on product quality and customer satisfaction.

Read More

Efficient Drink Filling Machines Streamline Production Processes

Drink Filling Machine Revolutionizes the Beverage IndustryIn a world where convenience and efficiency are of utmost importance, the beverage industry is no exception. The process of filling and packaging drinks has come a long way since the days of manually filling bottles, but there is always room for improvement. This is where the Drink Filling Machine comes into play.Developed by a leading engineering company, this revolutionary machine is designed to produce high-quality beverages quickly, efficiently, and with minimal human intervention. Whether you are a small start-up beverage company or a large corporation, the Drink Filling Machine can accommodate your needs.With its cutting-edge technology and state-of-the-art design, the Drink Filling Machine can handle a wide variety of beverages, from carbonated drinks to juices and water. The machine is versatile, customizable, and easy to use. It can be programmed to fill containers in different sizes and shapes, and the fill volume can be adjusted to the exact amount required for each container.Aside from its exceptional performance, the Drink Filling Machine also boasts of being eco-friendly. It reduces waste by using recyclable materials and has a low energy consumption rate, making it an environmentally responsible choice for any business.With its ability to produce up to 10,000 bottles per hour, the Drink Filling Machine is a game-changer for the beverage industry. It streamlines the production process, reduces labor costs, and maximizes efficiency, giving companies a competitive edge and the ability to produce high-quality beverages at a faster rate.The company behind the Drink Filling Machine is committed to providing excellent customer service. They offer installation, training, and maintenance services to ensure that the machine is running smoothly and efficiently at all times. They also provide technical support to help clients maximize their investment and get the most out of the machine.The Drink Filling Machine has already garnered a lot of attention in the beverage industry, and many companies are lining up to invest in the technology. With its ability to produce high-quality beverages quickly, efficiently, and with minimal environmental impact, it is clear that the Drink Filling Machine is the future of the beverage industry.The beverage industry is constantly evolving, and the Drink Filling Machine is proof that innovation is key to success. With its cutting-edge technology and eco-friendly design, this machine is sure to be a game-changer for the industry and pave the way for a more sustainable future.

Read More