Innovative Container Making Solutions for Your Packaging Needs

By:Admin

Container making is a crucial aspect of the packaging industry, and one company is taking significant steps to expand its operations in order to meet the growing demand for its products. With a strong focus on quality and innovation, [Company] is making waves in the industry, and its expansion plans are set to solidify its position as a leader in the container making business.

Established in [year], [Company] has quickly established itself as a trusted name in the packaging industry. With a commitment to producing high-quality containers and a dedication to meeting the needs of its customers, the company has experienced rapid growth in recent years. Its state-of-the-art manufacturing facilities and skilled team of professionals have allowed [Company] to offer a wide range of container options, catering to the diverse needs of various industries.

The company's expansion plans come at a time when the demand for containers is on the rise. As more businesses recognize the importance of packaging in brand identity and product protection, the need for high-quality, reliable containers has never been greater. [Company] is well-positioned to capitalize on this growing demand, and its expansion plans will allow it to further solidify its presence in the market.

In order to accommodate its growth and meet the increasing demand for its products, [Company] has announced plans to build a new, state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and machinery, allowing the company to increase its production capacity and streamline its operations. By doing so, [Company] aims to not only meet the current demand for its containers but also to prepare for future growth in the industry.

In addition to the new manufacturing facility, [Company] also plans to expand its product line to offer even more options to its customers. With a focus on innovation and customer satisfaction, the company is committed to developing new and improved container solutions that meet the evolving needs of its clients. By expanding its product line, [Company] aims to become a one-stop shop for all container needs, further solidifying its position as a market leader.

The expansion plans have generated excitement within the company and the industry as a whole. [Company] is known for its commitment to quality, innovation, and customer satisfaction, and the company's expansion plans are a testament to its dedication to these values. The new manufacturing facility and expanded product line will not only allow the company to better serve its existing customers but also attract new clients who are seeking high-quality container solutions.

As the company prepares for this significant expansion, it remains committed to its core values and mission. [Company] is dedicated to producing containers that meet the highest standards of quality and performance, and its expansion plans are a reflection of this dedication. By investing in new technology, machinery, and product development, the company is positioning itself for long-term success in the container making business.

Overall, the expansion plans announced by [Company] are set to further solidify the company's position as a leader in the container making industry. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for its products and continue to thrive in the industry. As the new manufacturing facility takes shape and the product line expands, [Company] is poised to make an even greater impact on the container making business.

Company News & Blog

Top Milk Packaging Machines: Streamline Your Production Process

Title: Cutting-Edge Milk Packing Machine Revolutionizes Dairy IndustryIntroduction:In modern times, technological advancements continuously reshape industries across all sectors. The dairy industry, in particular, is experiencing a transformation with the introduction of innovative equipment such as the advanced Milk Packing Machine. Developed by a leading machinery manufacturer, this state-of-the-art device promises to revolutionize the way milk is packaged, ensuring efficiency, accuracy, and optimal preservation of the product's quality.[Company Name], renowned for its expertise in engineering cutting-edge machinery, has launched the Milk Packing Machine to cater to the evolving needs of the dairy industry. This news piece will delve into the details of this groundbreaking equipment, its features, benefits, and its potential to reshape the milk packaging landscape.1. Enhanced Speed and Efficiency:The Milk Packing Machine incorporates advanced technology to streamline the packaging process. With its automated functionalities, it is capable of efficiently handling large volumes of milk, significantly reducing manual labor requirements. The machine's high-speed production capabilities ensure that milk packaging is executed smoothly and efficiently, meeting the demanding industry needs effectively.2. Precise Volume Measurements:One of the most critical factors in milk packaging is accuracy in volume measurements. The Milk Packing Machine incorporates advanced sensors and measuring systems that ensure precise quantities of milk are dispensed into each package. This not only minimizes wastage but also maintains consistency in product quality, enhancing customer satisfaction.3. Optimal Sealing and Preservation:The sealing process is vital to ensure milk freshness and prevent contamination. The Milk Packing Machine incorporates cutting-edge sealing technology, which utilizes heat and pressure to create airtight packages. This feature significantly extends the shelf life of the milk, ensuring that consumers receive a product of the highest quality.4. Versatile Packaging Options:The Milk Packing Machine offers a wide range of packaging options to cater to different consumer preferences and market demands. It enables packaging milk in various sizes, including bottles, tetra packs, and pouches. This versatility empowers dairy producers to adapt to changing market trends and meet the requirements of diverse customer segments.5. Improved Hygiene Standards:Maintaining hygiene is paramount in the dairy industry. The Milk Packing Machine features a robust stainless-steel construction, which is easy to clean and sanitize, ensuring that the highest hygiene standards are met. This minimizes the risk of contamination and ensures the safety of the packaged product.[Company Name] is dedicated to providing comprehensive support to its customers, including after-sales services and technical assistance. Their team of highly trained technicians offers routine maintenance and troubleshooting assistance to ensure uninterrupted productivity for dairy producers utilizing the Milk Packing Machine.Conclusion:The introduction of the advanced Milk Packing Machine by [Company Name] marks a significant milestone in the dairy industry. With its enhanced speed, accuracy in volume measurements, optimal sealing, versatile packaging options, and improved hygiene standards, this cutting-edge equipment represents a game-changer for milk packaging.As producers adapt to evolving consumer demands, this innovative technology allows them to meet market requirements efficiently and maintain the highest product quality. Dairy producers who embrace this vision of progress are set to gain a competitive edge, drive economic growth, and offer consumers milk that is both fresh and conveniently packaged.The Milk Packing Machine is poised to transform the dairy industry, and [Company Name] continues to be at the forefront of this revolution, driving the sector towards a more efficient, sustainable, and customer-centric future.

Innovative Container Making Solutions for Your Packaging Needs

Container Making Company Announces Expansion PlansContainer making is a crucial aspect of the packaging industry, and one company is taking significant steps to expand its operations in order to meet the growing demand for its products. With a strong focus on quality and innovation, [Company] is making waves in the industry, and its expansion plans are set to solidify its position as a leader in the container making business.Established in [year], [Company] has quickly established itself as a trusted name in the packaging industry. With a commitment to producing high-quality containers and a dedication to meeting the needs of its customers, the company has experienced rapid growth in recent years. Its state-of-the-art manufacturing facilities and skilled team of professionals have allowed [Company] to offer a wide range of container options, catering to the diverse needs of various industries.The company's expansion plans come at a time when the demand for containers is on the rise. As more businesses recognize the importance of packaging in brand identity and product protection, the need for high-quality, reliable containers has never been greater. [Company] is well-positioned to capitalize on this growing demand, and its expansion plans will allow it to further solidify its presence in the market.In order to accommodate its growth and meet the increasing demand for its products, [Company] has announced plans to build a new, state-of-the-art manufacturing facility. This facility will be equipped with the latest technology and machinery, allowing the company to increase its production capacity and streamline its operations. By doing so, [Company] aims to not only meet the current demand for its containers but also to prepare for future growth in the industry.In addition to the new manufacturing facility, [Company] also plans to expand its product line to offer even more options to its customers. With a focus on innovation and customer satisfaction, the company is committed to developing new and improved container solutions that meet the evolving needs of its clients. By expanding its product line, [Company] aims to become a one-stop shop for all container needs, further solidifying its position as a market leader.The expansion plans have generated excitement within the company and the industry as a whole. [Company] is known for its commitment to quality, innovation, and customer satisfaction, and the company's expansion plans are a testament to its dedication to these values. The new manufacturing facility and expanded product line will not only allow the company to better serve its existing customers but also attract new clients who are seeking high-quality container solutions.As the company prepares for this significant expansion, it remains committed to its core values and mission. [Company] is dedicated to producing containers that meet the highest standards of quality and performance, and its expansion plans are a reflection of this dedication. By investing in new technology, machinery, and product development, the company is positioning itself for long-term success in the container making business.Overall, the expansion plans announced by [Company] are set to further solidify the company's position as a leader in the container making industry. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for its products and continue to thrive in the industry. As the new manufacturing facility takes shape and the product line expands, [Company] is poised to make an even greater impact on the container making business.

Effortless Guide to Side Mounting License Plates for Your Vehicle

[Brand Name Removed] Introduces Innovative Side Mount License Plate for Enhanced Road Safety[date]In a move to revolutionize the traditional license plate placement on vehicles, [Brand Name Removed], a leading automotive accessory manufacturer, has announced the launch of their innovative Side Mount License Plate. This groundbreaking product aims to enhance road safety, improve visual aesthetics, and adhere to local regulations.The newly introduced Side Mount License Plate is designed to provide a unique and modern appearance to vehicles while ensuring compliance with legal requirements. Traditional license plates, when mounted at the center of the vehicle’s bumper or grille, can sometimes obstruct the driver's view, obstructing the line of sight. [Brand Name Removed]'s Side Mount License Plate eliminates this issue by placing the license plate on the side of the vehicle, allowing for unobstructed visibility.Aside from improved visibility, the Side Mount License Plate offers several other advantages. One of the most significant benefits is the reduction of traffic violations. Studies have shown that many drivers unintentionally block their license plates with accessories or because of misplacement, inadvertently attracting the attention of law enforcement. With the innovative side placement, drivers can rest assured knowing that their license plates are correctly and visibly displayed, minimizing the risk of being pulled over for such violations.Moreover, [Brand Name Removed]'s Side Mount License Plate is fully adjustable to fit different types of vehicles, making it a versatile solution for a wide range of automobile models. The product incorporates a user-friendly design that allows easy installation without the need for specialized tools. This convenience factor will undoubtedly be appreciated by vehicle owners who wish to upgrade their license plate placement without the hassle of extensive modifications.The Side Mount License Plate reflects [Brand Name Removed]'s commitment to quality and durability. Constructed from high-quality materials such as stainless steel or ABS plastic, the license plate holder is designed to withstand the rigors of everyday driving. It is resistant to various weather conditions, ensuring that the product remains steadfast and functional even in extreme temperatures or harsh environments.While the Side Mount License Plate meets the legal requirements and enhances safety, it also offers an opportunity for drivers to personalize their vehicles. [Brand Name Removed] understands the importance of personal expression, and they have designed the product to accommodate customization. Vehicle owners can choose from a range of available customization options, including a variety of color choices, finishes, and designs, ensuring that the license plate holder seamlessly fits with the overall aesthetic of their vehicle.Adhering to local regulations is an essential aspect of driving responsibly, and [Brand Name Removed] acknowledges the legal requirements associated with license plate placement. They have carefully conducted extensive research to develop the Side Mount License Plate, ensuring it complies with relevant laws and guidelines. Striking the right balance between style and compliance, this product proves to be a must-have for any driver seeking to enhance their vehicle's roadworthiness.The introduction of [Brand Name Removed]'s Side Mount License Plate marks a significant milestone in the automotive accessory industry. By combining improved road safety measures with stylish design options, this innovative product sets a new standard for license plate placement. As vehicle aesthetics continue to evolve, [Brand Name Removed] remains at the forefront, catering to the demands of discerning drivers who prioritize both safety and style.To learn more about [Brand Name Removed] and their groundbreaking Side Mount License Plate, visit their official website [website].About [Brand Name Removed]:[Brand Name Removed] is a prominent automotive accessory manufacturer specializing in creating innovative products that enhance vehicle performance and style. With a focus on quality, durability, and customer satisfaction, the company has gained a reputation for excellence in the industry. From license plate holders to other automotive accessories, [Brand Name Removed] continues to revolutionize the market with state-of-the-art products and exceptional service.

Aluminium C Profile: Key Features, Uses, and Benefits

Aluminium C Profiles: Revolutionizing the Construction IndustryAs the global construction industry continues to evolve, so does the demand for high-quality building materials. One such material, Aluminium C Profile (name removed), has emerged as an innovative solution that is revolutionizing the way structures are built. With its exceptional properties and versatile applications, Aluminium C Profile is becoming the go-to choice for architects, engineers, and construction professionals worldwide.Aluminium C Profile, also known as Aluminum C Channel, is a structural component made from aluminum alloys. Its unique C-shaped design, characterized by flanges on the top and bottom, provides excellent strength and support while maintaining a lightweight structure. The extrusion process used to manufacture Aluminium C Profile allows for a precise and consistent shape, ensuring uniformity and accuracy in construction projects.The versatility of Aluminium C Profile is one of its key advantages. Its adaptable design makes it suitable for a wide range of applications in diverse industries. In the construction sector, Aluminium C Profile is used for framework, supports, and structural components. Its high strength-to-weight ratio makes it an ideal choice for heavy-duty applications, such as building frames and roof trusses. Additionally, Aluminium C Profile can be easily fabricated and customized to meet specific project requirements, allowing for endless design possibilities.The corrosion-resistant properties of Aluminium C Profile make it highly durable and long-lasting, especially in harsh weather conditions. Unlike other metals, such as steel, aluminium does not rust, ensuring structural integrity and reducing maintenance costs over time. This makes Aluminium C Profile a cost-effective solution for a wide range of construction projects, including residential, commercial, and industrial buildings.Moreover, Aluminium C Profile is environmentally friendly. Aluminum is one of the most sustainable materials available, as it is 100% recyclable with no loss in quality. The recycling process requires only 5% of the energy needed to produce primary aluminum, making it an eco-friendly choice for reducing carbon emissions. The use of Aluminium C Profile in construction aligns with the growing trend of sustainable building practices, contributing to a greener and more sustainable future.One company that has been at the forefront of Aluminium C Profile production is the industry-leading manufacturer, {}. With their state-of-the-art facilities and cutting-edge technology, they have become synonymous with high-quality aluminium profiles. Their commitment to innovation, research, and development has allowed them to consistently deliver top-notch products that meet the highest industry standards.The {} company has a diverse range of Aluminium C Profiles catering to various industries and applications. Their profiles are manufactured using premium quality alloy, ensuring durability and reliability. The precise engineering and strict quality control processes followed by the company guarantee the delivery of consistent and reliable products to their esteemed customers.Furthermore, the company offers a range of customization options, allowing clients to tailor Aluminium C Profiles to their specific project needs. Their team of highly skilled engineers and designers work closely with clients to deliver bespoke solutions that meet their requirements. This dedication to customer satisfaction sets them apart from their competitors.In conclusion, Aluminium C Profiles are revolutionizing the construction industry with their exceptional properties and versatile applications. With their high strength, durability, and customization options, Aluminium C Profiles have become the go-to choice for construction professionals worldwide. The sustainable nature of aluminium, coupled with the commitment to innovation by leading manufacturers like {}, ensures a greener and more advanced future in construction.

Efficient Curd Packing Machines Streamline Dairy Production

Curd Packing Machine: Streamlining the Dairy Packaging ProcessThe dairy industry is one of the fastest-growing sectors worldwide. The high demand for dairy products has driven the need for efficient and innovative packaging solutions. Innovative packaging is essential to extend the shelf life and preserve the quality of dairy products, such as milk, yogurt, and cheese, in a way that meets the safety standards. This is where the Curd Packing Machine comes into play.The Curd Packing Machine is a specialized equipment designed to streamline the dairy packaging process. It is the result of innovative engineering that is intended to meet the unique needs of the dairy packaging industry.The machine offers automated packaging of curd in cups of various sizes. The process is efficient, and the machine can handle a large number of cups per hour. The machine is designed to minimize wastage, easy to operate and maintain, and saves labor costs.The company behind the Curd Packing Machine has been at the forefront of creating innovative packaging solutions for various industries. The company is committed to improving the safety and quality of food products, including dairy products. This is reflected in the design of the Curd Packing Machine, which ensures the highest standards of hygiene and prevents contamination of curd.The Curd Packing Machine is built with a robust framework that can withstand harsh processing conditions. It is engineered with precision and features high-quality components that ensure the machine's reliability and longevity. The machine's simple design facilitates easy inspection, cleaning, and maintenance, making it an ideal fit for dairy production facilities.The machine's automation ensures high productivity and reduces labor costs, making dairy packaging more efficient and cost-effective. The machine can handle various curd packaging requirements, including printing, sealing, and labeling. This streamlines the packaging process, increases yield, and results in more uniform and standardized packaging.The Curd Packing Machine uses the latest technologies to ensure accurate packaging and eliminate human error. The machine's sensors detect any deviations in the process and automatically adjust the packaging speed, ensuring consistent packaging and reducing wastage. The automation also ensures that the packaging process is fast, reducing the potential for contamination.The machine is highly adaptable, and its machines' configurations can be customized to suit the specific needs of dairy production facilities. The machine can handle flexible packaging designs, such as various cup sizes, shapes, and labels, and can even be customized to fit the color and design branding needs of individual manufacturers.The Curd Packing Machine has a small footprint, making it ideal for small production facilities with limited space. The machine's small size does not compromise its performance, and it can handle large production volumes.In conclusion, the Curd Packing Machine is a game-changer for the dairy packaging industry. Its innovative and efficient design, combined with the most cutting-edge technology, ensures the highest standards of quality and safety. The machine is an excellent fit for small, medium and large-scale dairy production facilities looking to increase their productivity and streamline their packaging process. The company's commitment to innovation, quality, and efficiency is evident in the Curd Packing Machine's design and is a testament to its commitment to creating sustainable growth for the dairy industry.

Benefits of Curved Corrugated Metal Panels for Your Building Projects

Title: Revolutionizing Construction: Curved Corrugated Metal Panels Redefine Structural DesignIntroduction:In an era where architecture and construction are constantly evolving, one innovative solution has emerged to redefine how structures are built. Curved corrugated metal panels have taken the industry by storm, offering a versatile and aesthetic option for building facades and roofing systems. [Company Name], a pioneering manufacturer in the field, has been at the forefront of the development and application of these groundbreaking panels.Paragraph 1:Curved corrugated metal panels have gained popularity rapidly due to their unique properties. These panels are made by forming metal sheets into a corrugated pattern, resulting in increased strength while reducing weight. The curvature of these panels allows builders and architects to create visually striking structures with enhanced durability.Paragraph 2:[Company Name], a leading manufacturer and provider of curved corrugated metal panels, has revolutionized the industry with their advanced designs and cutting-edge production techniques. By combining state-of-the-art technology with extensive research and development, the company has achieved unmatched quality and efficiency in their panel manufacturing process.Paragraph 3:One of the vital advantages of curved corrugated metal panels is their exceptional flexibility. Architects and designers can create unprecedented architectural forms by easily bending and shaping these panels to fit their desired structures. This flexibility is exemplified in projects that feature unique curves, arches, and other visually stunning designs. Such versatility has been harnessed in various applications such as stadiums, arenas, airports, commercial buildings, and residential projects.Paragraph 4:The aforementioned panels also boast remarkable durability and weather resistance. Manufactured using high-quality materials, they provide exceptional resistance to harsh weather conditions such as extreme temperatures, heavy rainfall, and windstorms. Combined with appropriate coatings, these panels also offer excellent protection against corrosion and wear, ensuring long-term performance and reduced maintenance costs.Paragraph 5:In addition to their structural and aesthetic qualities, curved corrugated metal panels have proven to be an environmentally friendly choice. These panels are often made from recyclable materials, reducing the carbon footprint associated with traditional construction materials. Furthermore, the lightweight nature of the panels allows for decreased energy consumption and transportation costs during installation.Paragraph 6:The growing demand for curved corrugated metal panels in the construction industry has led to an increased adoption rate among renowned architects and builders worldwide. With a track record of successful projects, [Company Name] has emerged as a trusted partner, providing reliable and customizable solutions backed by their technical expertise and commitment to customer satisfaction.Paragraph 7:To ensure the highest quality standards, [Company Name] employs a team of skilled engineers and technicians who closely monitor the manufacturing process at every stage. The company also offers design and engineering support, helping clients visualize their concepts and implement them effectively.Paragraph 8:As the construction industry continues to evolve, curved corrugated metal panels are set to play an increasingly significant role in shaping modern architecture. With their capacity to enhance aesthetic appeal, durability, and sustainability, these panels provide a sustainable and practical solution for meeting the ever-changing needs of the industry.Conclusion:Curved corrugated metal panels have revolutionized the construction industry, offering architects and builders an unparalleled combination of flexibility, aesthetic appeal, and durability. [Company Name] has played a pivotal role in advancing this technology, providing premium-quality solutions that have become synonymous with innovation and excellence. With an ever-growing demand for such panels, the future of construction is indeed curved.

New Study Reveals Surprising Insights into Sources of Friction in Top Industries

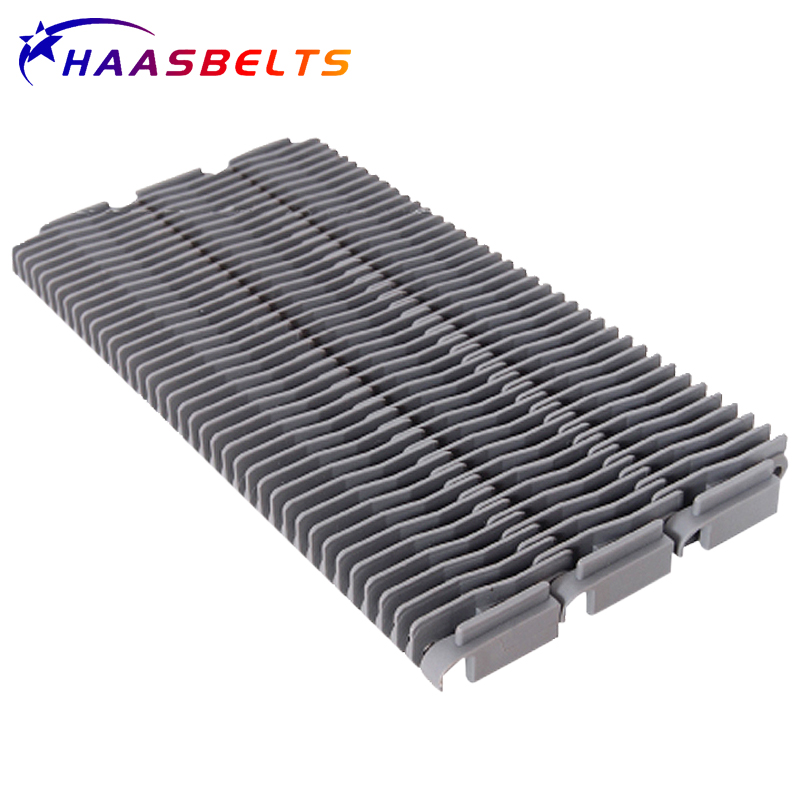

Friction Top conveyor belts are a key component in the manufacturing process of various industries. From food and beverage to automotive and manufacturing, these belts are used to transport items from one point to another efficiently. Founded in 1992, the company has been a trusted supplier of conveyor belts to industries worldwide for decades.Friction Top conveyor belts are designed to withstand some of the toughest conditions in production facilities. The belts are made from high-quality materials and are engineered to handle the heat, weight, and impact of heavy loads and fast-moving items. With the use of advanced technology, Friction Top conveyor belts offer excellent traction and grip, ensuring items are transported safely through the manufacturing process.One of the key advantages of Friction Top conveyor belts is their durability. These belts can handle heavy loads and constant use without breaking down. This means less downtime and maintenance for manufacturing facilities, resulting in increased production output and decreased costs.In addition, Friction Top conveyor belts are extremely versatile. They can be used in a variety of industries, such as food and beverage, automotive, packaging, and more. The belts can be customized to meet specific production requirements, such as size, material, and load capacity.The company has a team of experienced engineers and technicians who work closely with clients to design and manufacture conveyor belts that meet their specific needs. Friction Top conveyor belts can be made to fit almost any conveyor system, and the company offers installation and maintenance services to ensure the belts operate smoothly and efficiently.Friction Top conveyor belts are also designed with safety in mind. The belts have a non-slip surface, reducing the risk of accidents and injuries in the workplace. This is crucial in industries where heavy machinery and equipment are in use.The company is committed to sustainability and environmental responsibility. Friction Top conveyor belts are made from eco-friendly materials and processes, reducing their impact on the environment. The company also offers recycling services for used conveyor belts, ensuring they are disposed of responsibly.Friction Top conveyor belts have received international recognition for their quality and performance. The company has been awarded various certifications, including ISO 9001, ISO 14001, and OHSAS 18001. These certifications demonstrate the company's commitment to excellence, quality, and safety.Overall, Friction Top conveyor belts are an essential component in the manufacturing process of various industries. With their durability, versatility, and safety features, they are a reliable and cost-effective solution for transporting items through the production line. The company's commitment to sustainability and environmental responsibility also sets them apart as a leader in the industry.

Beverage Transport Made Easy with Innovative Conveyor Belt Technology

Conveyor Belt For Beverage Transport - Improving Efficiency in the Beverage IndustryThe beverage industry is one of the largest and most significant industries globally, with a wide range of brands and products available in the market. The industry is highly competitive, and companies must continually find new ways to improve their manufacturing processes to remain competitive. One essential aspect of this process is the transportation of products within the manufacturing plant. Beverage manufacturing companies must ensure that their products are transported efficiently, quickly, and without any error or damage.The conveyor belt is an excellent solution for the transportation of products within a manufacturing plant. Over the years, the conveyor belt has become an essential piece of equipment in the beverage industry due to its ability to move products quickly and efficiently. Conveyor belts are designed to transport a wide range of products, from raw materials to finished products, and also aid in the automation of the manufacturing process.One of the most significant benefits of conveyor belts is the ability to move products over long distances, allowing companies to optimize their manufacturing plants’ layout. Conveyor belts are also designed to handle large volumes of products, which are essential in the beverage industry. Machines on the conveyor belt can sort, transport, and even package products, thereby improving the manufacturing process's overall efficiency.Once the product is on the conveyor belt, the machine can transport the products from one plant operation to another, without needing manual intervention. This inherent automation increases production speed, reduces operating costs, and prevents product damage in the manufacturing process, all while ensuring uniformity and consistency in product preparation.One company, which has developed an innovative beverage conveyor belt solution, is a global leader in the design and manufacture of beverage manufacturing technology. They have designed a comprehensive and flexible solution that is tailored to the specific requirements of beverage product handling, transport and logistics.The company's conveyor belt solution is designed to meet the high standards of the beverage industry and improve production efficiency. The system is a modular belt conveyor system, which is highly flexible and can be customized to meet the specific needs of a company. The modular design allows for easy installation and maintenance, which helps reduce equipment downtime and maintenance costs for manufacturers.The system also boasts a range of features that are designed to prevent errors and ensure the safe handling of products. For example, the products transported on the conveyor belt are never in direct contact with the belt material, preventing any contamination from foreign particles.The conveyor belt system also features user-friendly controls that allow operators to easily adjust parameters such as speed. This feature provides control over product flow, allowing for changes to the manufacturing process as needed without impacting overall efficiency.The design of the conveyor belt system is also geared towards reducing energy consumption. The conveyor belting design reduces system energy use by up to 30% compared to other conventional conveying solutions. Therefore, the system provides an eco-friendly solution, reducing the carbon footprint of beverage manufacturers. The conveyor belt also incorporates advanced conveyor engineering designs that minimize maintenance, maximizing uptime, reducing operating costs, and eliminating downtime.The company has designed the conveyor belt system for easy integration with other systems within the manufacturing plant. It is also designed to be highly flexible, enabling manufacturers to scale up or down as needed without having to invest in new equipment. The system’s versatility has made it a top choice for manufacturers in the beverage industry.ConclusionThe conveyor belt's efficiency and cost-effectiveness make it an essential piece of equipment in the beverage industry. The range of benefits the system provides helps manufacturers to improve their manufacturing process’s overall efficiency and profitability. With the innovative design presented by the company, manufacturers can benefit from a comprehensive and flexible solution that is tailored to their specific requirements of beverage product handling, transport and logistics, which ultimately reflects positively on product quality and customer satisfaction.

Discover the Benefits of Flush Grid Friction Top Conveyor Belts

In today's world, conveyor belts have become an integral part of the manufacturing process. They ensure that products are transported safely and efficiently from one point to another. Conveyor belt designs have come a long way, incorporating various innovations to meet the specific needs of different industries.One such innovation in the conveyor belt industry is the flush grid friction top design. This unique design is gaining popularity due to its numerous benefits, which are helping industries to automate their operations, reduce downtime, increase production, and enhance product quality, among others.Flush grid friction top belts have a series of evenly spaced openings arranged in a grid pattern on the belt's surface. This design gives the conveyor belt an excellent grip on the products being transported, preventing slippage, and ensuring that the products maintain their position on the conveyor belt. The openings in the flush grid design also allow for easy and thorough cleaning, making it ideal for the food and beverage industry, where hygiene is paramount.One company that is at the forefront of designing and manufacturing flush grid friction top belts is {} (). The company has been in the conveyor belt industry for over 40 years, and its experience and expertise enable it to create high-quality conveyor belts that meet the varying needs of different industries.{} () offers a range of flush grid friction top belts that are tailored to the specific requirements of each industry. Their belts are versatile and suitable for various industries, including food and beverage, pharmaceutical, automotive, and electronics, among others. The company's flush grid friction top belts are made from high-quality materials that are durable and resistant to wear and tear, ensuring they have a long lifespan, reducing the need for frequent replacements.In addition to manufacturing flush grid friction top belts, {} () also provides customization services. The company can design and manufacture conveyor belts that meet the unique needs of their clients. They can tailor the belt's width, length, thickness, and surface pattern, among other specifications, depending on the client's requirements.One of the features that set {} () apart from other conveyor belt manufacturers is their commitment to quality and customer satisfaction. The company has invested in state-of-the-art equipment and employs a team of experienced professionals who ensure that each belt that leaves their facilities meets the company's high standards. They also offer excellent customer service, providing technical support and advice to clients, ensuring they make an informed decision when selecting a conveyor belt.The flush grid friction top design has numerous benefits that are revolutionizing the conveyor belt industry. Industries that have adopted this design have noticed a significant improvement in their production processes, resulting in increased efficiency, reduced downtime, and enhanced product quality.In conclusion, {} () is a leading manufacturer of flush grid friction top conveyor belts, providing high-quality products that meet the diverse needs of different industries. Their commitment to excellence and customer satisfaction makes them the ideal partner for industries seeking to optimize their production processes. With their expertise and state-of-the-art equipment, {} () is poised to continue leading the industry in innovation and exceptional service delivery.

Efficient and Reliable Milk Packing Machine: A Game-Changer for the Dairy Industry

[Company Introduction]Established in the early 2000s, our company has been a leading manufacturer and supplier of dairy processing equipment across the globe. With our commitment to innovation and customer satisfaction, we have successfully carved a niche for ourselves in the highly competitive dairy industry.Our state-of-the-art manufacturing facility, located in [City, Country], houses advanced machinery and technology to ensure the production of high-quality and efficient dairy processing equipment. We take pride in our team of highly experienced engineers and technicians who work tirelessly to develop cutting-edge solutions that meet the evolving needs of our customers.As a socially responsible company, we adhere to strict quality control measures and employ sustainable manufacturing practices. We believe in the importance of reducing our environmental footprint at every stage of the production process, from sourcing materials to recycling waste. Our dedication to sustainability has earned us several certifications and accolades, positioning us as a trusted partner in the industry.[News Content]Title: Revolutionary Milk Packaging Machine Facilitates Efficiency and Ensures Quality[City, Country] - In a bid to enhance efficiency and maintain the highest quality standards in milk packaging, [Company name] has introduced its groundbreaking Milk Packing Machine. This state-of-the-art equipment promises to revolutionize the dairy industry, providing a reliable, cost-effective, and sustainable solution for milk packaging.The flagship packaging machine boasts an array of innovative features that streamline the milk packaging process. Utilizing cutting-edge technology, it facilitates high-speed filling, sealing, and labeling, ensuring optimal productivity for dairy manufacturers. The machine's advanced sensors and controls guarantee accurate fill levels, minimizing waste and maximizing output.Moreover, the Milk Packing Machine has been meticulously designed to preserve the freshness and quality of milk. With robust sealing mechanisms and airtight packaging, it prevents contamination and extends shelf life, reducing the chances of spoilage and ensuring consumer satisfaction. The equipment also accommodates a range of packaging sizes, catering to the diverse needs of dairy producers.One of the standout features of this packaging machine is its user-friendly interface. The intuitive control panel simplifies operation and minimizes the training requirements for machine operators, making it accessible for both experienced personnel and newcomers in the dairy industry. Additionally, the machine's modular design allows for easy maintenance and quick troubleshooting, minimizing downtime and maximizing productivity.The Milk Packing Machine is not only efficient and user-friendly but also environmentally conscious. As a company committed to sustainability, we have integrated energy-efficient components and materials into the equipment's design. This includes optimized power consumption, recyclable packaging materials, and a reduction in water usage during the cleaning process. By investing in this state-of-the-art packaging machine, dairy manufacturers can contribute to their environmental goals and reduce their carbon footprint."We are thrilled to introduce the Milk Packing Machine to the market," said [Company spokesperson]. "Our extensive research and development efforts have resulted in a packaging solution that helps our clients achieve operational excellence while upholding the highest standards of milk quality and safety. This machine not only increases efficiency and minimizes wastage but also ensures that end-consumers receive fresh, uncontaminated milk products."The Milk Packing Machine has already garnered positive feedback from several leading dairy manufacturers who have witnessed its transformative impact on their operations. As we continue to refine and enhance our technology, we remain dedicated to providing innovative solutions that address the evolving needs of the dairy industry.In conclusion, [Company name]'s revolutionary Milk Packing Machine presents a game-changing solution for the dairy industry. With its advanced features, exceptional efficiency, and commitment to sustainability, this equipment sets new standards for milk packaging. As the industry looks to optimize processes and deliver superior products, the Milk Packing Machine emerges as an indispensable tool for dairy manufacturers striving for excellence.