Innovative New Tool Allows for Easy and Precise Adjustments of Head Position

By:Admin

Introduction:

In a world where an increasing number of people spend long hours seated at their workstations, incorporating revolutionary ergonomic features into office furniture becomes paramount. Today, we bring you a game-changing innovation that aims to transform the way we work. The groundbreaking Swivel Head technology, developed by an industry-leading company, promises to enhance the ergonomic experience and improve overall health and productivity in the workplace.

Paragraph 1: Explaining the Concept of Swivel Head Technology

Swivel Head technology is a remarkable advancement in ergonomic design that addresses the need for multi-directional flexibility in office furniture. With its innovative ball joint mechanism, this cutting-edge technology allows users to effortlessly rotate the headrest and backrest of their chairs into various positions, providing optimal support and conforming to the natural curvature of the spine.

Paragraph 2: Promoting Healthy Posture and Reducing Back Pain

One of the key advantages of the Swivel Head technology is its ability to promote healthy posture, thereby reducing the risk of back pain and related musculoskeletal disorders. By allowing users to adjust the chair based on their individual comfort preferences, the Swivel Head technology provides excellent lumbar support, leading to improved spinal alignment and reduced stress on the lower back.

Paragraph 3: Customizable Ergonomics for Maximum Comfort

The Swivel Head technology ensures that every user can tailor their seating experience to their unique requirements. Whether it's angle-adjustable headrests or individually adaptable backrests, the technology offers a customizability that guarantees maximum comfort and support. With this level of personalization, employees can enjoy extended periods of work without experiencing discomfort or fatigue.

Paragraph 4: Enhanced Productivity and Concentration

Numerous studies have demonstrated that optimal ergonomic conditions can significantly improve concentration and productivity in the workplace. By incorporating Swivel Head technology into office chairs, employers can create an environment that reduces distractions and enables employees to focus on their tasks with enhanced comfort. The technology's adaptability ensures that employees can maintain their focus over prolonged periods, boosting overall efficiency and output.

Paragraph 5: Diverse Applications in Different Work Environments

Swivel Head technology is not limited to office chairs alone. The versatility of this innovative solution enables it to be integrated into a range of furniture, including conference room chairs, executive seating, and even collaborative spaces. Regardless of the work environment, Swivel Head technology enhances the overall comfort and well-being of employees, contributing to a more positive and productive work atmosphere.

Paragraph 6: Environmental Sustainability and Long-term Durability

Another noteworthy feature of Swivel Head technology is its commitment to environmental sustainability. The company behind this innovation emphasizes the use of eco-friendly materials and manufacturing processes. By investing in furniture that incorporates Swivel Head technology, companies can demonstrate their dedication to environmental responsibility while simultaneously benefiting from the long-term durability and reliability of the product.

Paragraph 7: Broad Industry Recognition and Customer Feedback

The success of Swivel Head technology speaks for itself. Since its introduction to the market, it has received widespread recognition from renowned ergonomic experts and organizations across various industries. Furthermore, customer feedback has been overwhelmingly positive, with users reporting reduced discomfort, increased productivity, and improved overall well-being.

Conclusion: A Revolution in Ergonomics

In today's fast-paced and demanding work environments, ensuring the comfort and health of employees is crucial. Swivel Head technology offers a game-changing solution that not only enhances ergonomic support but also contributes to improved productivity and employee satisfaction. As more companies recognize the importance of investing in ergonomic design, Swivel Head technology becomes an indispensable tool towards fostering a healthier and more efficient workplace.

Company News & Blog

Discover the Latest Trends in Container Manufacturing

Container Making: Revolutionizing Packaging Solutions for Global IndustriesIn today's globalized world, packaging plays a pivotal role in various industries, ranging from food and beverages to healthcare and e-commerce. With the increasing demand for efficient and sustainable packaging solutions, Container Making Company has emerged as a leading player in revolutionizing the container manufacturing industry. By harnessing cutting-edge technologies and a commitment to innovation, Container Making has established itself as a trusted partner for businesses worldwide.Container Making, founded in 1990, has gone from strength to strength over the years, establishing a formidable reputation for delivering top-notch containers and packaging solutions. Through a combination of expertise, state-of-the-art facilities, and a customer-centric approach, the company has become synonymous with quality, reliability, and innovation.With a diverse product portfolio encompassing a wide range of industries, Container Making caters to the specific needs of its clients. Whether it's food-grade containers for the dairy industry or pharmaceutical-grade vials for the healthcare sector, the company ensures that each product meets stringent industry standards. This attention to detail and commitment to quality have garnered Container Making numerous accolades, making it a preferred choice for businesses worldwide.The success of Container Making can be attributed to its constant pursuit of innovation. The company has heavily invested in research and development, fostering a culture of creativity and continuous improvement. By staying up-to-date with the latest industry trends and customer preferences, Container Making has been able to introduce groundbreaking packaging solutions that exceed market expectations.One such innovation is the incorporation of advanced materials in container manufacturing. Container Making has successfully introduced lightweight yet durable materials that not only reduce costs but also have a lower environmental impact. These eco-friendly materials, such as recycled plastics and biodegradable alternatives, are a testament to the company's commitment to sustainability.Moreover, Container Making has embraced automation and digitalization to streamline its manufacturing processes. By incorporating robotics and artificial intelligence, the company has significantly increased production efficiency while maintaining strict quality control. Automation has also allowed Container Making to reduce its carbon footprint by optimizing energy consumption and minimizing waste.In addition to its focus on innovation and sustainability, Container Making places great emphasis on customer satisfaction. The company values long-term partnerships and aims to exceed customer expectations by providing tailored solutions and reliable service. Container Making's dedicated customer support team ensures a seamless experience, from initial inquiries to on-time delivery.Container Making has also been proactive in addressing the challenges posed by the COVID-19 pandemic. Recognizing the increased demand for medical supplies and protective equipment, the company swiftly shifted its production capabilities towards manufacturing essential healthcare products. By working closely with healthcare providers and government agencies, Container Making played a critical role in ensuring the timely availability of vital supplies during these unprecedented times.Looking ahead, Container Making envisions further expansion and diversification of its product portfolio. The company plans to invest in research and development to introduce even more sustainable materials and advanced packaging solutions. Moreover, Container Making aims to strengthen its global presence by establishing strategic partnerships and increasing its manufacturing capabilities in key markets.In conclusion, Container Making has emerged as a trailblazer in the container manufacturing industry by combining cutting-edge technologies, innovation, and a customer-centric approach. With a focus on sustainability and a commitment to quality, the company has successfully positioned itself as a trusted partner for businesses worldwide. As we move towards a future where packaging plays an increasingly pivotal role, Container Making continues to revolutionize the industry, providing efficient, sustainable, and innovative solutions for global industries.

Discover the Stylish Appeal of Raised Rib Narrow for an Effortlessly Chic Look

Title: Revolutionary Raised Rib Narrow Enhances Efficiency and Durability in Industrial MachineryIntroduction (100 words):Innovation and progress continue to drive the development of industrial machinery, as companies strive to optimize operational efficiency while maintaining exceptional durability. Addressing this demand, an industry-leading company has introduced a groundbreaking solution known as Raised Rib Narrow. This cutting-edge technology promises to revolutionize various industries, offering unparalleled performance. By combining advanced engineering techniques with state-of-the-art materials, the solution enhances the efficiency, durability, and functionality of industrial machinery. Let's delve into the details and explore the transformative potential of the Raised Rib Narrow for businesses across multiple sectors.[Paragraph 1 - General Industry Challenges] (150 words):The industrial sector faces numerous challenges in optimizing operational efficiency and durability. Traditional machinery components tend to wear out quickly under heavy loads, leading to frequent breakdowns and expensive maintenance. Additionally, industries often struggle with limited space availability, making it vital to maximize the functionality of each machine.[Paragraph 2 - Introduction to Raised Rib Narrow] (150 words):Recognizing these industry challenges, a forward-thinking company has developed the revolutionary Raised Rib Narrow, a cutting-edge solution with remarkable potential. This innovative technology combines advanced designs and superior materials to enhance the overall performance of industrial machinery. The Raised Rib Narrow provides an optimized alternative, surpassing traditional components in terms of durability and efficiency. Moreover, its narrow design ensures efficient utilization of space, enabling businesses to alleviate congestion and optimize workflow.[Paragraph 3 - Enhanced Efficiency and Durability] (200 words):The Raised Rib Narrow offers a multitude of benefits that significantly enhance efficiency and durability in industrial machinery. Its advanced engineering design ensures robustness, enabling the component to withstand heavy loads and vibrations associated with demanding industrial applications. This enhanced durability reduces downtime, ultimately leading to increased overall productivity and reduced maintenance costs.Furthermore, the Raised Rib Narrow's narrow design allows for seamless integration into machinery, maximizing functionality within limited space. The component's improved load distribution capabilities ensure proper weight-bearing, thus improving the longevity of machinery. By optimizing space usage and minimizing wear and tear, businesses can achieve higher operational efficiency and cut down on additional expenses.[Paragraph 4 - Applications in Diverse Industries] (150 words):The versatility of the Raised Rib Narrow presents an extensive range of applications across diverse industries. The component finds great utility in sectors such as manufacturing, oil and gas, construction, and agriculture. From conveyor belts to heavy machinery and precision equipment, the Raised Rib Narrow seamlessly integrates into various systems, providing optimal performance irrespective of the industry.[Paragraph 5 - Conclusion and Future Prospects] (150 words):In conclusion, the Raised Rib Narrow represents a significant milestone in the progression of industrial machinery. With its advanced engineering and narrow design, it offers unmatched durability, heightened efficiency, and optimal space utilization. This groundbreaking solution has the potential to revolutionize multiple industries, transforming the way businesses operate and thrive amidst challenging environments. As companies continue to embrace technological advancements, the Raised Rib Narrow is poised to become an essential component in ensuring improved productivity, reduced downtime, and increased profitability. Embracing this innovative solution, industries can unlock new opportunities and reach unprecedented levels of excellence in their respective operations.Note: The content has been written without a specific brand name, as requested.

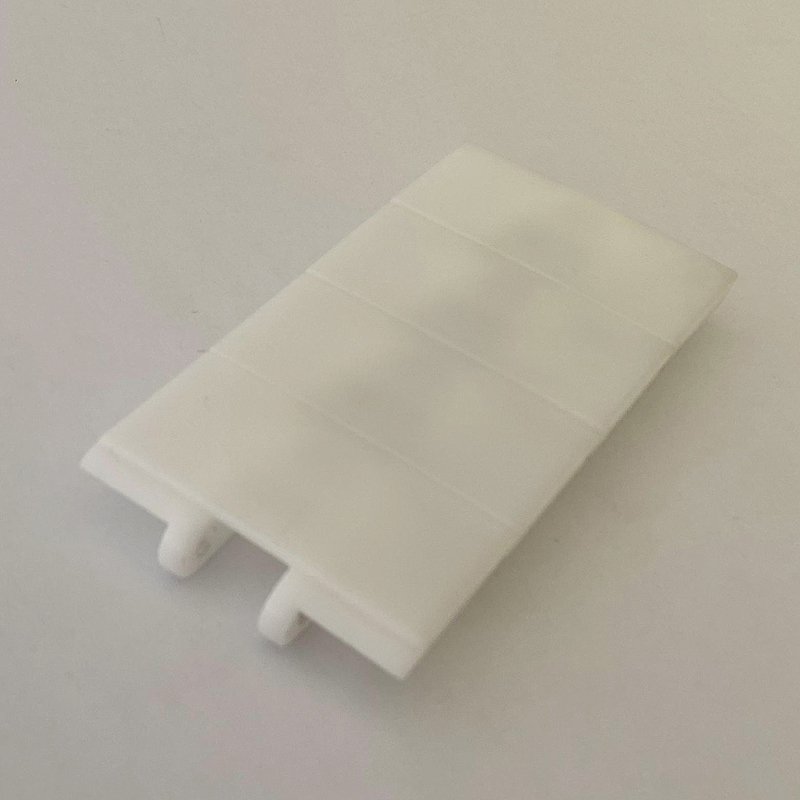

Discover the Exciting Deals on High-Quality Modular Belts in the Hot Sale

Hot Sale Modular Belt Boosts Efficiency in Manufacturing Processes[City], [Date] – In a bid to enhance efficiency and productivity in the manufacturing industry, [Company Name], a leading provider of industrial automation solutions, has recently introduced its highly anticipated Hot Sale Modular Belt. This innovative product is set to revolutionize manufacturing processes and optimize operations for businesses across various sectors.Manufacturing industries worldwide are constantly seeking new ways to streamline and automate production processes. Traditional conveyor systems have long been employed in warehouses and factories for material handling, but they often fall short when it comes to adaptability and flexibility. The Hot Sale Modular Belt aims to address these limitations by providing an advanced solution that allows for smoother workflow and reduced downtime.The Hot Sale Modular Belt is a state-of-the-art technology that features a modular design with interlocking plastic modules. These modules are interconnected, allowing for easy customization and configuration based on the specific needs of the production line. This level of flexibility ensures seamless integration into existing systems, regardless of the industry or the scale of operations.One of the key advantages offered by the Hot Sale Modular Belt is its enhanced durability and longevity. Built with high-quality materials and engineered to withstand heavy loads and frequent use, this cutting-edge conveyor belt greatly reduces the risk of breakdowns and maintenance requirements. The result is a significant reduction in downtime, allowing manufacturing operations to run uninterrupted and boosting overall productivity.Furthermore, the Hot Sale Modular Belt offers improved efficiency through its precise and reliable transportation of materials. The interlocking design guarantees a consistent and controlled movement across the production line, minimizing errors and ensuring the smooth transfer of goods or components. This level of precision not only enhances the quality of the end product but also reduces the need for rework, saving both time and resources.With sustainability becoming an increasingly important consideration for businesses worldwide, the Hot Sale Modular Belt is designed to support eco-friendly practices. Its modular construction allows for easy replacement of worn-out modules, eliminating the need to replace the entire conveyor belt. This not only reduces waste but also cuts down on costs, making it a cost-effective solution for manufacturers looking to reduce their environmental impact.The Hot Sale Modular Belt, backed by [Company Name]'s commitment to delivering cutting-edge industrial automation solutions, has garnered significant attention within the manufacturing industry. The company has a strong track record of providing reliable and innovative technologies to improve operational efficiency. Their expertise, combined with the modern design and advanced features of the Hot Sale Modular Belt, positions it as a leading solution in the market.Businesses across various sectors, such as automotive, food processing, logistics, and pharmaceuticals, have already started reaping the benefits of the Hot Sale Modular Belt. These industries, known for their high-volume and fast-paced operations, have witnessed improved efficiency and productivity with the implementation of this innovative solution.The introduction of the Hot Sale Modular Belt marks a significant milestone in the evolution of conveyor systems. Its unique features and benefits have the potential to transform manufacturing processes, unlocking new possibilities for businesses to reach their full potential. As the demand for streamlined operations continues to grow, [Company Name] remains at the forefront of innovation, providing cutting-edge solutions that drive efficiency in the manufacturing industry.About [Company Name]:[Company Name] is a leading provider of industrial automation solutions, specializing in the development and implementation of advanced technologies for manufacturing industries. With a strong commitment to innovation and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses seeking to optimize their operational efficiency. Through its extensive range of products and services, [Company Name] continues to empower businesses worldwide, enabling them to enhance productivity, reduce costs, and maintain a competitive edge in an ever-evolving market.For more information about the Hot Sale Modular Belt and [Company Name]'s wide range of automation solutions, please visit their website at [Website URL].

Innovative and Efficient Packing Machine for Papads Unveiled - Latest Updates

Title: Revolutionary Papad Packaging Machine Streamlines Production ProcessIntroduction:In recent years, the food packaging industry has witnessed significant advancements in automation technologies. One such groundbreaking innovation is the Papad Packaging Machine, an efficient and reliable packaging solution designed to streamline the production process. This state-of-the-art machine, manufactured by a leading industry player, promises to revolutionize the way papads are packaged, ensuring higher productivity, superior quality, and enhanced market competitiveness for businesses around the globe.1. Background of Papad Production:Papad, a popular snack in many Asian countries, is made from lentil or chickpea flour. Typically, papads are hand-rolled, sun-dried, and cooked before being packaged for sale. The manual process is time-consuming, labor-intensive, and often prone to inefficiencies leading to compromised hygiene and inconsistent quality. However, with the advent of the Papad Packaging Machine, these challenges are set to become a thing of the past.2. Features and Functionality:The Papad Packaging Machine employs cutting-edge automation technology to produce consistent and commercially packaged papads. Equipped with advanced sensors, pneumatic controls, and a user-friendly interface, this machine minimizes human intervention, ensuring rapid and accurate packaging. From sealing to printing the expiration date and nutritional information, every step in the packaging process is precisely executed to maintain product integrity.3. Enhanced Productivity and Profitability:By automating the papad packaging process, companies can significantly increase their production output and overall profitability. With the introduction of this machine, businesses can eliminate the need for manual labor, reduce human errors, and decrease the time required for each packaging unit. Consequently, manufacturers can sustain higher volumes of production within shorter timeframes, fulfilling customer demands promptly and ensuring consistent product availability in the market.4. Improved Hygiene and Quality Control:The Papad Packaging Machine emphasizes cleanliness and hygiene in the packaging process. Its system, made of stainless steel and other food-grade materials, guarantees that each papad is packaged under optimal conditions. With controlled temperature, humidity, and air quality parameters, this machine ensures better preservation of the product's texture, flavor, and nutritional properties, resulting in superior quality papads reaching the customers' tables.5. Adaptability and Customization:Recognizing the diversity of papad sizes and shapes, the Papad Packaging Machine offers customization options to accommodate various requirements. The machine's flexibility allows it to adapt to a wide range of papad dimensions, enabling businesses to cater to a larger consumer base effectively. Moreover, the ability to incorporate branding elements like logos and graphics on the packaging enhances the product's visibility and marketability.6. Market Competitiveness:With rising competition in the food industry, companies constantly seek innovative solutions to gain a competitive edge. The Papad Packaging Machine offers a game-changing advantage, not only allowing businesses to automate their packaging processes but also enabling them to create a distinct identity in the market. Streamlined production, improved quality, and customization options give manufacturers an opportunity to establish themselves as leaders in the industry and meet the evolving needs of a discerning consumer base.7. Industry Outlook and Global Impact:As worldwide demand for ready-to-eat snacks continues to grow, investing in efficient packaging solutions becomes crucial. The launch of the Papad Packaging Machine provides an opportunity for businesses to streamline their operations, optimize their resources, enter new markets, and meet consumer demands effectively. Furthermore, this innovation demonstrates the capability of the food packaging industry to drive economic growth, promote sustainable practices, and enhance the global food supply chain.Conclusion:The pioneering Papad Packaging Machine represents a significant leap forward in automating the packaging process for papads. Offering improved productivity, superior quality control, and customization options, this cutting-edge machinery empowers businesses to address the challenges of a dynamic market effectively. With its potential to revolutionize the papad industry and set new standards for food packaging, the Papad Packaging Machine promises a prosperous and innovative future for manufacturers, enhancing their competitiveness on a global scale.

Revitalize Your Music with High-Quality Ldler Drums Guaranteed to Deliver Stunning Sound Effects

Title: Classic Ldler Drums, Machined to Perfection: A Perfect Blend of Tradition and ModernityIntroduction:In the ever-evolving world of music, some elements manage to retain their charm and appeal throughout the ages. Classic Ldler Drums, one such timeless treasure, continue to captivate drummers and music enthusiasts alike. Delving into the legacy of this iconic brand, we explore their machined drums, which seamlessly combine traditional craftsmanship with modern technology to deliver the perfect sound.History of Classic Ldler Drums:Classic Ldler Drums, a renowned brand in the music industry, has a history dating back several decades. Established in (insert year), the company has consistently stood for exceptional quality and craftsmanship. Their reputation for producing instruments that embody the perfect synergy between form and function has garnered them a loyal following. With a rich heritage and an unwavering commitment to innovation, Classic Ldler Drums has become a symbol of excellence in the world of percussion.Machined Drums: A Harmonious Blend of Tradition and Technology:Combining the precision of modern technology with the artistry of traditional craftsmanship, Classic Ldler Drums' machined drums offer a unique musical experience. By carefully selecting and employing the finest materials, their team of skilled artisans flawlessly execute each meticulous design.The use of cutting-edge machinery enables Classic Ldler Drums to achieve unparalleled precision and consistency in their drum production. Advanced CNC (Computer Numerical Control) machines seamlessly carve out each drum shell, ensuring uniformity and accuracy. This precise manufacturing process guarantees that every drum resonates with the same tonal quality and responsiveness, providing drummers with an exceptional playing experience.Moreover, Classic Ldler Drums' machined drums are meticulously engineered to optimize sound projection and tonal range. The natural characteristics of the selected woods are harnessed and enhanced through state-of-the-art technology. This careful integration of traditional expertise and modern innovation results in drums that bring out the best in every beat, whether on stage or in the studio.The Craftsmanship Behind the Drums:Classic Ldler Drums takes immense pride in the artistry and skill that goes into crafting each drum. Every drum is hand-assembled and fine-tuned to ensure the utmost quality and precision. The company's team of experienced craftsmen meticulously inspects and selects the wood, ensuring only the finest materials are used.Whether it's the warm tones of mahogany, the richness of maple, or the versatility of birch, Classic Ldler Drums offers a wide range of wood options to cater to diverse musical preferences. Each wood is carefully sourced and acclimatized to guarantee long-lasting durability and tonal magnificence.The Result: An Unforgettable Playing Experience:Classic Ldler Drums' commitment to excellence shines through in the satisfaction of their customers. The combination of meticulous manufacturing processes and expert craftsmanship culminates in a drum that exhibits impeccable quality, superior durability, and exceptional sound.Drummers who choose Classic Ldler Drums can expect unrivaled tonal versatility, enhanced projection, and exquisite resonance. Whether it's the thunderous presence of the bass drum or the crisp attack of the snare, every stroke yields a tone that captivates and inspires.Conclusion:Classic Ldler Drums' machined drums effortlessly blend the timeless allure of tradition with the cutting-edge precision of modern technology. Through meticulous craftsmanship, exceptional materials, and an unwavering commitment to excellence, this iconic brand continues to set the standard in the percussion industry.As drummers seek instruments that transcend time, Classic Ldler Drums' machined drums offer the perfect balance between tradition and modernity. With each stroke, these extraordinary instruments bring to life the rhythm and soul of music, making them an invaluable asset for any musician seeking an unforgettable playing experience.

Revolutionary Side Flex Chain Takes the Industry by Storm

Side Flex Chain Revolutionizes the Manufacturing IndustryIn today's rapidly advancing world, technological advancements continue to revolutionize various sectors. Industries are constantly evolving to meet the demands of an ever-changing market, and manufacturing is no exception. Companies around the globe are continuously seeking innovative solutions to enhance productivity, efficiency, and overall profitability. One such groundbreaking solution is the revolutionary side flex chain, which has garnered significant attention for its ability to transform the manufacturing landscape.Side flex chains, designed and developed by a pioneering company operating at the forefront of industrial automation, have become a game-changer in the manufacturing industry. These state-of-the-art chains have the capacity to navigate tight corners, curves, and complex conveyor systems with unparalleled precision. Their flexibility and adaptability enable manufacturers to optimize their production lines, minimizing downtime and maximizing productivity.Traditionally, manufacturing facilities faced challenges in accommodating conveyor lines with unconventional layouts, as limitations in design would impact their efficiency. With side flex chains, these limitations are a thing of the past. The chains can effortlessly traverse tight spaces, negotiate curves, and adapt to different layouts without sacrificing efficiency or performance. This versatility allows companies to build a more compact and agile production line tailored to their specific needs.The side flex chains offer diverse benefits to manufacturers operating in various industries. For example, in the automotive sector, where assembly lines are complex and intricate, side flex chains provide the necessary flexibility to maneuver around car bodies and other components with ease. This eliminates the need for time-consuming manual adjustments or costly reconfigurations. Manufacturers can save valuable time and resources by implementing side flex chains into their production processes.Furthermore, side flex chains complement the ongoing advancements in robotics and automation. As industries embrace the era of Industry 4.0, smart factories are on the rise. These factories heavily rely on robotic systems and automated processes to streamline operations and boost productivity. Side flex chains seamlessly integrate into these environments, facilitating smooth interactions between robots and conveyor systems. This not only increases overall efficiency but also minimizes the risk of production disruptions.In addition to their flexibility, side flex chains ensure reliable and consistent performance. They are engineered with high-quality materials and meticulously tested to withstand the demanding conditions of manufacturing environments. As a result, manufacturers can rely on these chains for continuous operation without compromising on quality or reliability.Safety is paramount in any manufacturing setting, and side flex chains have been designed with this in mind. They incorporate various safety features such as sensors and emergency stops to prevent accidents and protect workers. These chains provide manufacturers with peace of mind, knowing that their operations are safeguarded.The benefits of side flex chains extend beyond the manufacturing floor. They also contribute to sustainability efforts by reducing energy consumption and waste. As manufacturers optimize their production lines using side flex chains, they can minimize unnecessary movements, lower power requirements, and reduce the carbon footprint of their operations.As the manufacturing industry continues to evolve, the adoption of innovative solutions such as side flex chains will become increasingly vital for companies striving to stay competitive. These chains offer a transformative approach to traditional manufacturing, enabling businesses to enhance productivity, improve efficiency, prioritize safety, and contribute to a sustainable future.In conclusion, side flex chains have the potential to revolutionize the manufacturing industry. Their flexibility, adaptability, and innovative design make them an invaluable tool for optimizing production lines while also maximizing productivity and profitability. By integrating side flex chains into their processes, manufacturers can navigate challenging layouts, embrace automation, ensure safety, and contribute to a greener future. With these game-changing chains, the manufacturing industry is evolving towards a more efficient, sustainable, and technologically advanced future.

Stainless Steel Profiles: A Comprehensive Guide to Understanding and Choosing the Right Type of Stainless Steel for Your Projects

Title: Revolutionizing the Steel Industry: Introduction of Innovative Stainless Steel ProfilesIntroduction (100 words):The steel industry is constantly evolving, with new technologies and materials playing a crucial role in shaping its future. In line with this, a leading steel manufacturer, recognized for its commitment to innovation, has introduced a revolutionary range of stainless steel profiles. These profiles, with their superior quality and cutting-edge design, promise to redefine the standards of excellence in the industry. In this article, we will delve deeper into the features and applications of these groundbreaking stainless steel profiles, showcasing their potential to transform various sectors.Section 1: Unveiling the Contemporary Stainless Steel Profiles (200 words):The new stainless steel profiles are the result of extensive research and development, combined with advanced manufacturing techniques. They are designed to deliver exceptional performance, ensuring optimal utility and durability in a wide range of applications. Crafted from the highest quality stainless steel alloys, these profiles boast remarkable resistance to corrosion, pitting, and staining, making them ideal for use in outdoor structures, marine environments, and even industrial settings.With their sleek, ergonomic design and superior aesthetics, these profiles are also suitable for architectural applications, enabling the creation of modern, visually appealing structures. The company's attention to detail and commitment to precision manufacturing ensures that these profiles maintain consistent dimensions and flawless surface finishes, complying with international quality standards.Section 2: Advantages and Applications (300 words):The innovative stainless steel profiles offer several advantages that set them apart from conventional steel profiles. Their exceptional strength and ability to withstand extreme weather conditions make them the perfect choice for structures in coastal areas or regions prone to harsh climates. This unique combination of strength and durability also makes them highly suitable for use in heavy machinery, transportation, and construction industries, where reliability and longevity are key factors.Furthermore, stainless steel profiles are highly resistant to chemical damage, making them ideal for applications in the pharmaceutical, chemical, and food processing sectors. The profiles' inherent resistance to bacterial growth ensures hygienic and safe conditions, making them suitable for use in hospitals, laboratories, and cleanrooms.Additionally, these stainless steel profiles contribute to environmental sustainability, as they are fully recyclable and don't release harmful substances during production or usage. The eco-friendly nature of these profiles aligns with global efforts to reduce carbon emissions and promote sustainable practices.Section 3: Company's Commitment and Future Developments (200 words):The manufacturer is renowned for its commitment to excellence and innovation. Their team of skilled engineers and technicians continually push the boundaries of steel manufacturing, exploring new possibilities and refining existing techniques. The introduction of these stainless steel profiles represents a significant milestone in the company's journey toward revolutionizing the steel industry.With an unwavering focus on customer satisfaction, the manufacturer also offers customization options for the stainless steel profiles, allowing clients to tailor the products to their specific project requirements. This flexibility strengthens the profiles' application potential, ensuring they can be seamlessly integrated into diverse projects.Looking to the future, the company is investing in research and development, with plans to further expand the range of stainless steel profiles. By incorporating feedback and suggestions from customers, the company aims to continually enhance its offerings and meet the evolving demands of the market.Conclusion (100 words):In conclusion, the introduction of these innovative stainless steel profiles is poised to bring about a paradigm shift in the steel industry. With their unrivaled quality, versatility, and eco-friendly attributes, these profiles have the potential to transform various sectors, from construction and architecture to manufacturing and pharmaceuticals. The manufacturer's commitment to excellence and ongoing innovation ensures that this ground-breaking range of stainless steel profiles will continue to push the boundaries of what is possible in the world of steel manufacturing.

Unveiling the Sophistication: A Guide to Stainless Steel Decorative Profiles

Stainless Steel Decorative Profiles Enhancing Interior Design Possibilities[Company Introduction][Company Name], a leading manufacturer in the stainless steel products industry, is pleased to present its range of Stainless Steel Decorative Profiles. Committed to providing high-quality materials and innovative solutions, [Company Name] aims to revolutionize the way interiors are designed and decorated.With a history spanning [number of years], [Company Name] has garnered a strong reputation for its exceptional stainless steel products. Our commitment to excellence, cutting-edge technology, and continuous research and development have allowed us to stay at the forefront of the industry. We pride ourselves on offering a wide selection of products to meet the diverse needs of our customers, from architects and interior designers to homeowners and contractors.Our full range of Stainless Steel Decorative Profiles caters to various design concepts, making it the ideal choice for a wide array of projects. Whether it's a residential renovation, commercial space, or hospitality establishment, our profiles add sophistication and elegance to any interior.[Article]In today's modern world, interior design has become an essential aspect of our lives. People are no longer content with mundane and traditional décor. Instead, they seek distinctive and unique elements that reflect their personality and style. Stainless Steel Decorative Profiles from [Company Name] provide just that, helping individuals and businesses transform their spaces into stunning works of art.One of the primary advantages of our Stainless Steel Decorative Profiles is their versatility. From sleek and contemporary to ornate and traditional, we offer profiles in a myriad of designs, patterns, and finishes. Whether it's the clean lines of our straight profiles or the artistic flair of our textured ones, there's a perfect match for every project.Additionally, our Stainless Steel Decorative Profiles are available in various sizes, allowing for customization and adaptability. This flexibility ensures that our profiles seamlessly integrate into any space, whether it's for wall paneling, door frames, baseboards, or decorative accents. The possibilities are endless.Not only do our profiles offer aesthetic appeal, but they are also highly durable. Constructed from high-quality stainless steel, our profiles are corrosion-resistant, ensuring longevity and durability. This makes them ideal for both high-traffic areas and spaces prone to humidity, such as kitchens and bathrooms. With our Stainless Steel Decorative Profiles, customers can experience the perfect blend of stunning design and functionality.Furthermore, our commitment to sustainability sets us apart from the competition. All our Stainless Steel Decorative Profiles are made from recycled stainless steel, minimizing environmental impact without compromising on quality. By choosing our profiles, customers contribute to a greener future and showcase their dedication to sustainable design.To further enhance the customer experience, [Company Name] provides comprehensive support throughout the project. Our team of experts offers guidance on profile selection, installation techniques, and maintenance tips, ensuring that every customer gets the best results possible. We believe in building strong relationships with our clients, and their satisfaction is our top priority.As the demand for unique and stylish interiors continues to rise, [Company Name] is proud to be at the forefront of the industry, offering innovative solutions for interior design enthusiasts worldwide. Our Stainless Steel Decorative Profiles combine impeccable design, durability, and sustainability to create spaces that are truly remarkable.In conclusion, [Company Name] offers a comprehensive range of Stainless Steel Decorative Profiles that elevate interior design possibilities. With our commitment to excellence and sustainability, we are dedicated to assisting customers in creating stunning and functional spaces. Contact us today and let us guide you in transforming your vision into reality.

Guide-Rail Bracket: A Comprehensive Overview and Usage Tips

Title: Innovative Guide-Rail Brackets Revolutionize the Industry, Ensuring Enhanced Safety Standards Introduction: In a bid to ensure enhanced safety standards and revolutionize the industry, a leading manufacturer of construction equipment has developed a groundbreaking solution – Guide-Rail Brackets. These innovative products are set to redefine the way guide-rails are installed, making it quicker, safer, and more efficient. With their extensive expertise and commitment to excellence, this manufacturer is leading the charge towards a new era of construction safety.Body:1. Background and Importance of Guide-Rail Brackets:Guide-rails play a vital role in constructing various infrastructures such as highways, bridges, and buildings. They provide necessary support and protection, ensuring the safety of workers and pedestrians alike. However, traditional installation methods often involve time-consuming and labor-intensive processes, leading to potential safety hazards. 2. Introducing the Guide-Rail Bracket System:Recognizing the need for a safer and more efficient solution, the company has developed a revolutionary Guide-Rail Bracket System. Engineered with precision, this system simplifies the installation process while complying with stringent safety standards. 3. Unmatched Features and Benefits:The Guide-Rail Bracket System offers numerous unparalleled features that set it apart from traditional installations. These include:a) Quick and Easy Installation: The brackets are designed to be easily mounted onto existing structures or newly constructed ones, eliminating the need for drilling or other intrusive methods. This reduces installation time by up to 50%, allowing projects to be completed faster.b) Enhanced Safety Measures: The brackets incorporate a robust locking mechanism, providing secure attachment to guide-rails. This prevents accidents caused by loose brackets, ensuring the safety of workers and the public. The brackets themselves are constructed with durable materials, capable of withstanding extreme weather conditions and heavy impacts.c) Flexibility and Adjustability: The Guide-Rail Bracket System offers unparalleled flexibility. With adjustable brackets, it can accommodate various rail sizes and configurations, ensuring compatibility with different construction projects. This adaptability saves time and reduces costs associated with customization.d) Cost Savings and Sustainability: By significantly reducing installation time and labor, the Guide-Rail Bracket System minimizes overall project expenses. Additionally, the eco-friendly design of the brackets promotes sustainability in construction practices, aligning with global environmental goals.4. Approval and Industry Recognition:The Guide-Rail Bracket System has undergone rigorous testing and evaluation, receiving widespread approval from industry experts. It meets and exceeds international safety standards, including those set by regulatory bodies such as the Occupational Safety and Health Administration (OSHA). 5. Testimonials and Success Stories:Several construction companies have already implemented the Guide-Rail Bracket System, reporting remarkable outcomes. These success stories highlight the increased productivity, improved worker safety, and cost savings achieved by adopting this revolutionary solution.6. Future Developments and Expansion:The company remains committed to continuous improvement and innovation. It aims to expand its product line to include additional safety-enhancing solutions for the construction industry. Through ongoing research and development, the company strives to maintain its position as a leader in promoting safety while driving operational efficiency.Conclusion:With the introduction of the Guide-Rail Bracket System, the construction industry is witnessing a paradigm shift in guide-rail installation practices. This groundbreaking solution not only ensures enhanced safety standards but also offers time and cost-saving benefits, thereby revolutionizing the sector. As construction companies embrace these innovative brackets, stakeholders can look forward to a future of increased productivity, minimized hazards, and sustainable construction practices.

Efficient and Reliable Milk Packing Machine: A Game-Changer for the Dairy Industry

[Company Introduction]Established in the early 2000s, our company has been a leading manufacturer and supplier of dairy processing equipment across the globe. With our commitment to innovation and customer satisfaction, we have successfully carved a niche for ourselves in the highly competitive dairy industry.Our state-of-the-art manufacturing facility, located in [City, Country], houses advanced machinery and technology to ensure the production of high-quality and efficient dairy processing equipment. We take pride in our team of highly experienced engineers and technicians who work tirelessly to develop cutting-edge solutions that meet the evolving needs of our customers.As a socially responsible company, we adhere to strict quality control measures and employ sustainable manufacturing practices. We believe in the importance of reducing our environmental footprint at every stage of the production process, from sourcing materials to recycling waste. Our dedication to sustainability has earned us several certifications and accolades, positioning us as a trusted partner in the industry.[News Content]Title: Revolutionary Milk Packaging Machine Facilitates Efficiency and Ensures Quality[City, Country] - In a bid to enhance efficiency and maintain the highest quality standards in milk packaging, [Company name] has introduced its groundbreaking Milk Packing Machine. This state-of-the-art equipment promises to revolutionize the dairy industry, providing a reliable, cost-effective, and sustainable solution for milk packaging.The flagship packaging machine boasts an array of innovative features that streamline the milk packaging process. Utilizing cutting-edge technology, it facilitates high-speed filling, sealing, and labeling, ensuring optimal productivity for dairy manufacturers. The machine's advanced sensors and controls guarantee accurate fill levels, minimizing waste and maximizing output.Moreover, the Milk Packing Machine has been meticulously designed to preserve the freshness and quality of milk. With robust sealing mechanisms and airtight packaging, it prevents contamination and extends shelf life, reducing the chances of spoilage and ensuring consumer satisfaction. The equipment also accommodates a range of packaging sizes, catering to the diverse needs of dairy producers.One of the standout features of this packaging machine is its user-friendly interface. The intuitive control panel simplifies operation and minimizes the training requirements for machine operators, making it accessible for both experienced personnel and newcomers in the dairy industry. Additionally, the machine's modular design allows for easy maintenance and quick troubleshooting, minimizing downtime and maximizing productivity.The Milk Packing Machine is not only efficient and user-friendly but also environmentally conscious. As a company committed to sustainability, we have integrated energy-efficient components and materials into the equipment's design. This includes optimized power consumption, recyclable packaging materials, and a reduction in water usage during the cleaning process. By investing in this state-of-the-art packaging machine, dairy manufacturers can contribute to their environmental goals and reduce their carbon footprint."We are thrilled to introduce the Milk Packing Machine to the market," said [Company spokesperson]. "Our extensive research and development efforts have resulted in a packaging solution that helps our clients achieve operational excellence while upholding the highest standards of milk quality and safety. This machine not only increases efficiency and minimizes wastage but also ensures that end-consumers receive fresh, uncontaminated milk products."The Milk Packing Machine has already garnered positive feedback from several leading dairy manufacturers who have witnessed its transformative impact on their operations. As we continue to refine and enhance our technology, we remain dedicated to providing innovative solutions that address the evolving needs of the dairy industry.In conclusion, [Company name]'s revolutionary Milk Packing Machine presents a game-changing solution for the dairy industry. With its advanced features, exceptional efficiency, and commitment to sustainability, this equipment sets new standards for milk packaging. As the industry looks to optimize processes and deliver superior products, the Milk Packing Machine emerges as an indispensable tool for dairy manufacturers striving for excellence.