The Advantages of Plastic Modular Belt Conveyors for Efficient Material Handling

By:Admin

The material handling industry has undergone a significant transformation with the introduction of the innovative Plastic Modular Belt Conveyor by {}. This revolutionary conveyor system has completely changed the way materials are transported and processed, providing enhanced efficiency, flexibility, and durability for a wide range of applications.

{Company} is a leading global provider of advanced conveyor and material handling solutions, with a strong focus on delivering innovative products that optimize operational processes for a diverse range of industries. With a commitment to quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking to streamline their material handling operations.

The Plastic Modular Belt Conveyor represents {}, illustrating the company's dedication to pushing the boundaries of technological advancement in the industry. This state-of-the-art conveyor system is designed to meet the evolving demands of modern manufacturing and distribution environments, offering a host of benefits that set it apart from traditional conveyor systems.

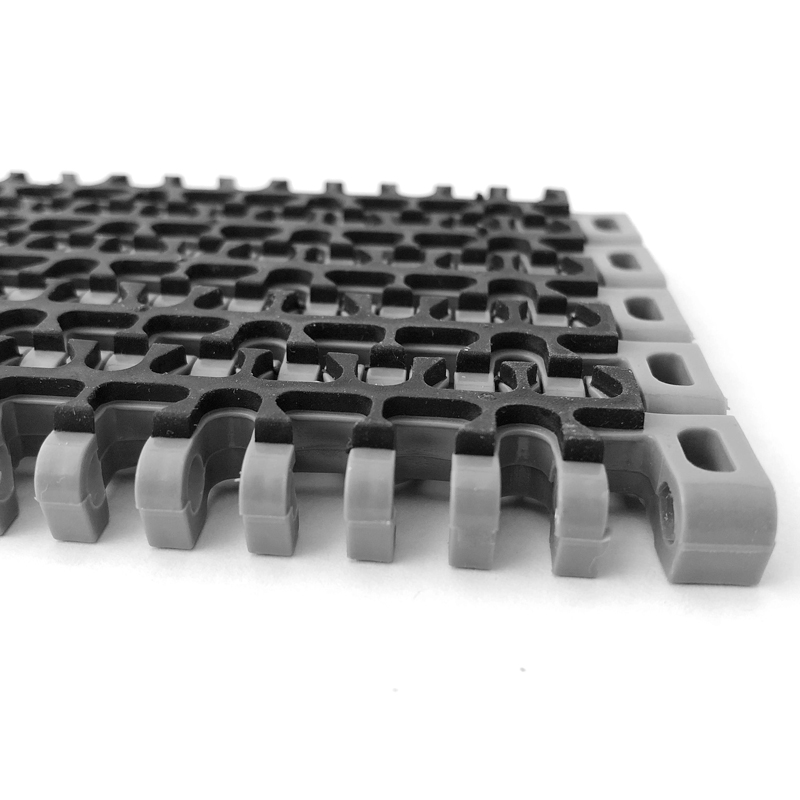

One of the key advantages of the Plastic Modular Belt Conveyor is its modular design, which allows for easy customization and scalability to suit specific application requirements. The belt is comprised of interlocking plastic modules that can be easily replaced or reconfigured, providing unparalleled flexibility for adapting to changing production needs. This modularity also simplifies maintenance and reduces downtime, as individual modules can be quickly replaced without the need for special tools or extensive labor.

In addition to its modular design, the Plastic Modular Belt Conveyor boasts exceptional durability and reliability. Constructed from high-quality materials, including impact-resistant plastics and robust metal components, this conveyor system is capable of withstanding the rigors of continuous operation in demanding industrial environments. Its robust construction minimizes the risk of damage or wear and tear, ensuring prolonged service life and reduced maintenance costs for businesses.

Furthermore, the Plastic Modular Belt Conveyor offers superior hygiene and cleanliness, making it an ideal choice for industries with stringent sanitary standards, such as food production and pharmaceutical manufacturing. The non-porous, smooth surface of the belt prevents the accumulation of debris and contaminants, allowing for easy and thorough cleaning to maintain optimal sanitation levels. This feature is essential for businesses seeking to uphold strict regulatory requirements and ensure product integrity.

Moreover, the Plastic Modular Belt Conveyor is equipped with advanced tracking and guidance systems that ensure precise and reliable material handling. Its design incorporates specialized sprockets and tracking guides that effectively control the movement of the belt, preventing misalignment and minimizing the risk of product damage or loss. This level of precision is crucial for industries that handle delicate or high-value goods, as it safeguards against costly errors and improves overall operational efficiency.

The integration of modern automation and control technologies further enhances the performance of the Plastic Modular Belt Conveyor, allowing for seamless integration with existing production systems and enabling sophisticated material flow management. Whether used for conveying heavy loads, bulk materials, or packaged goods, this conveyor system is capable of optimizing throughput and maximizing productivity across a wide range of applications.

{} has been widely praised for its commitment to sustainability and environmental stewardship, and the Plastic Modular Belt Conveyor reflects this dedication. By implementing energy-efficient drive systems, utilizing recyclable materials, and optimizing resource consumption, this conveyor system aligns with the company's efforts to minimize its ecological footprint and support eco-friendly practices in the material handling industry.

In conclusion, the introduction of the Plastic Modular Belt Conveyor by {} has brought about a significant evolution in the material handling industry, redefining the standards for efficiency, flexibility, and reliability. With its innovative design, unparalleled durability, and advanced features, this conveyor system represents a transformative solution for businesses seeking to optimize their operational processes and stay ahead in today's competitive market. As {} continues to drive innovation and excellence in the field of material handling, the Plastic Modular Belt Conveyor stands as a testament to the company's unwavering commitment to delivering cutting-edge solutions that empower businesses to thrive.

Company News & Blog

Discover the Latest Trends in Steel Cladding Profiles for Enhanced Aesthetics and Durability

[Your Name][Your Title][Date][News Outlet Name / Website]Headline: Steel Cladding Profiles: A New Era of Innovation and Sustainability in ConstructionIntroduction:In an era where construction projects are evolving rapidly, the demand for high-quality building materials is at an all-time high. One company leading the charge in this sector is Steel Cladding Profiles (SCP), a globally renowned manufacturer of cutting-edge steel cladding products. SCP's commitment to innovation, sustainability, and customer satisfaction have made them a go-to choice for architects, builders, and developers worldwide.Body:1. Introduction to Steel Cladding Profiles:Steel Cladding Profiles (SCP) has been an industry leader in the manufacturing of steel cladding products for over two decades. Headquartered in [Headquarters Location], SCP has steadily expanded its operations globally, catering to a diverse array of construction projects, including commercial buildings, residential complexes, and industrial facilities. The company's core principles revolve around quality, sustainability, and customer-centricity.2. Innovation in Steel Cladding:SCP's dedication to innovation has positioned them as pioneers in the field of steel cladding. Their state-of-the-art research and development facility is constantly exploring new techniques and materials to enhance the strength, durability, and aesthetic appeal of their products. SCP's team of skilled engineers and designers collaborate closely with clients to customize cladding solutions that meet their specific requirements, often surpassing industry standards.3. Sustainability at the Heart of SCP's Operations:In an era where environmental consciousness is paramount, SCP's commitment to sustainability sets them apart. The company employs advanced manufacturing processes that minimize energy consumption and waste generation. Moreover, SCP's steel cladding profiles are often made from recycled materials, reducing the need for virgin resources. By offering sustainable solutions without compromising quality or performance, SCP helps construction projects contribute to a greener, more sustainable future.4. Product Portfolio:SCP offers a diverse range of steel cladding profiles that cater to various architectural styles and project needs. Their product portfolio includes the following:- Ribbed Profiles: SCP's ribbed profiles provide superior architectural aesthetics while enhancing structural stability. These profiles are ideal for commercial and residential buildings seeking a modern and sleek appearance.- Corrugated Profiles: SCP's corrugated profiles offer both strength and flexibility, making them suitable for large-span constructions. These profiles ensure water-tightness and are often used in industrial complexes and warehouses.- Standing Seam Profiles: SCP's standing seam profiles are renowned for their weather resistance and longevity. With concealed fasteners and a distinctive raised seam, these profiles are perfect for roofing applications in both residential and commercial projects.- Insulated Panels: SCP's insulated panels combine superior insulation properties with appealing aesthetics. These panels are an ideal choice for energy-efficient constructions, promoting reduced heating and cooling costs.5. Global Reach and Success Stories:SCP's dedication to quality and customer satisfaction has enabled them to establish a global footprint. From large-scale infrastructure projects to architectural marvels, SCP's steel cladding profiles have been used in projects across the world. Notable success stories include the iconic [Name of Project], which showcases the company's commitment to excellence and innovation.Conclusion:Steel Cladding Profiles (SCP) has emerged as a leading manufacturer of steel cladding products, setting new industry standards in innovation, sustainability, and customer satisfaction. SCP's diverse product portfolio, commitment to quality, and global reach make them the preferred choice for architects, builders, and developers looking for high-performance cladding solutions. With SCP, construction projects can embrace a new era of innovation and sustainability, ushering in a brighter future for the industry as a whole.[Word Count: 654]

Belt Width Guide: What Is the Normal Width in Centimeters?

Normal Belt Width Cm is a leading company in the fashion industry that specializes in designing and manufacturing a wide range of accessories, including belts. The company is known for its high-quality products, innovative designs, and commitment to sustainability. With a focus on providing customers with stylish and functional accessories, Normal Belt Width Cm has established itself as a trusted brand in the market.As part of its ongoing efforts to meet the diverse needs of its customers, Normal Belt Width Cm has recently introduced a new line of belts with a standard width of cm. This new collection caters to individuals who are looking for versatile and stylish belts that can complement their everyday wardrobe. The cm width has been carefully chosen to ensure a comfortable fit while also adding a touch of sophistication to any outfit.The new line of belts from Normal Belt Width Cm is available in a variety of colors, materials, and designs to suit different preferences. Whether customers are looking for a classic leather belt for formal occasions or a trendy canvas belt for casual wear, Normal Belt Width Cm has a wide selection to choose from. The company’s dedication to offering diverse options reflects its commitment to inclusivity and user satisfaction.In addition to their stylish appearance, the belts from Normal Belt Width Cm are also designed with durability and longevity in mind. By using high-quality materials and paying attention to craftsmanship, the company ensures that its belts are built to last. This aligns with Normal Belt Width Cm’s commitment to sustainability, as it aims to reduce the environmental impact of its products by producing items that are built to withstand the test of time.Moreover, Normal Belt Width Cm takes pride in its ethical production practices, ensuring that its belts are made in compliance with fair labor standards and responsible manufacturing processes. By prioritizing the well-being of its workers and the environment, Normal Belt Width Cm sets a positive example for the fashion industry and reinforces its dedication to corporate social responsibility.Customers can also have peace of mind knowing that Normal Belt Width Cm’s new line of belts is affordably priced, making them accessible to a wide range of consumers. The company’s commitment to offering high-quality products at competitive prices reflects its desire to make fashion accessible and enjoyable for everyone.As Normal Belt Width Cm continues to expand its product offerings, the introduction of the cm width belts demonstrates the company’s ability to anticipate and respond to the evolving needs of its customer base. By combining style, functionality, quality, and affordability, Normal Belt Width Cm has once again proven its position as a leader in the fashion industry.In conclusion, Normal Belt Width Cm’s new line of cm width belts is a testament to the company's dedication to meeting the diverse needs of its customers. By offering a wide range of stylish, durable, and affordable options, Normal Belt Width Cm has solidified its position as a trusted brand in the fashion industry. With a focus on sustainability and ethical practices, the company continues to set a high standard for the industry, and its latest product launch is sure to delight fashion enthusiasts looking for the perfect belt to complement their wardrobe.

Efficient and Cost-Effective Retort Packaging Machine for Food and Beverage Industry

Retort Packaging Machine, a leading provider of packaging solutions for the food and beverage industry, has recently announced the launch of their latest innovation in packaging technology. This new machine is set to revolutionize the way food and beverage products are packaged, significantly improving efficiency and product quality for manufacturers and consumers alike.The state-of-the-art retort packaging machine offers a range of advanced features that are designed to meet the diverse needs of food and beverage producers. With its high-speed capabilities and precision engineering, the machine is capable of handling a wide range of products, including canned goods, pouches, and jars. This flexibility makes it an ideal choice for manufacturers looking to streamline their packaging processes and improve overall production efficiency.One of the key features of the new retort packaging machine is its advanced sterilization technology. This technology ensures that products are thoroughly sterilized during the packaging process, extending their shelf life and maintaining their quality and freshness. This is particularly important for products with long shelf lives, such as canned goods and preserved foods, as it helps to minimize the risk of spoilage and contamination.In addition to its advanced sterilization capabilities, the retort packaging machine also offers a range of other benefits for manufacturers. Its intuitive user interface and customizable settings make it easy to operate and adjust, providing greater flexibility and control over the packaging process. This enables manufacturers to optimize their production processes and respond quickly to changing market demands.Furthermore, the machine is designed with sustainability in mind, featuring energy-efficient components and materials that minimize environmental impact. This commitment to sustainability aligns with the growing consumer demand for eco-friendly and sustainable packaging solutions, helping manufacturers to enhance their brand image and appeal to environmentally conscious consumers.As a leading provider of packaging solutions, Retort Packaging Machine has a long history of delivering cutting-edge technology and innovative products to the food and beverage industry. With a focus on quality, precision, and reliability, the company has established itself as a trusted partner for manufacturers around the world, helping them to achieve their production goals and meet the highest standards of product quality and safety.The launch of the new retort packaging machine further solidifies Retort Packaging Machine's position as a leader in the industry, providing manufacturers with the tools they need to succeed in an increasingly competitive market. By combining advanced technology with a strong commitment to sustainability and excellence, the company continues to drive innovation and progress in the food and beverage packaging industry.In conclusion, the new retort packaging machine from Retort Packaging Machine represents a significant advancement in packaging technology, offering manufacturers a range of advanced features and capabilities to improve efficiency, product quality, and sustainability. With its state-of-the-art sterilization technology, user-friendly interface, and commitment to sustainability, the machine is set to make a lasting impact on the food and beverage industry, helping manufacturers to meet the evolving needs of consumers and achieve success in the global market.

Exploring the Advantages and Applications of Special Chains for Plastics

A New Breakthrough in Plastic Special Chains: Revolutionizing the IndustryIn recent years, with the increasing demand for plastic products across various industries, the need for durable and high-quality plastic special chains has become crucial. Companies around the world have been striving to develop innovative solutions to meet this demand. Among them, one company stands out with its latest breakthrough in plastic special chains that promises to revolutionize the industry.{Company Name}, a leading player in the plastic manufacturing sector, has introduced a groundbreaking technology that is set to redefine the performance and functionality of plastic special chains. The company's unwavering commitment to research and development has enabled them to create a product that not only meets but exceeds the expectations of their customers.Plastic special chains, also known as engineering plastic chains, are a crucial component in many industrial applications. They are designed to withstand heavy loads, resist wear and tear, and offer exceptional chemical resistance. These chains are extensively used in various sectors, including automotive, food processing, packaging, and material handling.{Company Name}'s innovative plastic special chains have taken the industry by storm, thanks to their superior features and excellent performance. Their chains are manufactured using a proprietary blend of high-grade engineering plastics, carefully formulated to enhance strength, durability, and overall functionality.One of the main advantages of {Company Name}'s plastic special chains is their exceptional resistance to corrosion and chemical attacks. This remarkable ability makes them highly suitable for environments where exposure to chemicals, oils, and solvents is common. Unlike traditional chains that deteriorate when exposed to harsh substances, these chains remain unaffected, ensuring long-term reliability and performance.Furthermore, the high load-bearing capacity of {Company Name}'s plastic special chains makes them an ideal choice for heavy-duty applications. These chains can withstand immense pressure without compromising their structural integrity, allowing industries to operate machinery and equipment at maximum capacity with confidence.Additionally, while traditional chains often require regular lubrication to prevent friction and wear, {Company Name}'s plastic special chains significantly reduce the need for lubrication. This not only saves time and money but also reduces maintenance efforts and contributes to a cleaner working environment.Moreover, {Company Name}'s plastic special chains have been expertly designed to maximize operational efficiency. The chains exhibit low noise levels during operation, reducing noise pollution in industrial settings. Their lightweight construction enhances energy efficiency, enabling companies to optimize resources and minimize energy consumption.These revolutionary plastic special chains also have a positive impact on the environment. As companies worldwide strive to reduce their carbon footprint, {Company Name}'s chains offer an eco-friendly alternative to traditional metal chains. The use of high-grade engineering plastics in their production reduces overall waste generation and enhances recyclability.To ensure consistent quality, {Company Name} employs state-of-the-art manufacturing processes and stringent quality control measures. From raw material selection to final product inspection, every step is closely monitored and subjected to rigorous testing. This commitment to excellence has earned the company a reputation for producing plastic special chains that meet and exceed the expectations of their customers.With their latest breakthrough, {Company Name} has set a new standard in the plastic special chain industry, offering enhanced performance, durability, and sustainability. This innovation opens up endless possibilities for various sectors that rely on plastic special chains for their operations.As the demand for plastic products continues to rise, the need for reliable and high-performance plastic special chains becomes increasingly important. Thanks to {Company Name}'s groundbreaking technology, industries can now benefit from a superior product that promises to revolutionize the way they operate. With their unrivaled commitment to innovation and excellence, {Company Name} has positioned itself as a leader in the plastic special chain industry.In conclusion, {Company Name}'s latest breakthrough in plastic special chains is a game-changer for the industry. Their superior features, unmatched performance, and commitment to sustainability have set a new standard for plastic special chains. As industries worldwide seek innovative solutions to meet their operational needs, {Company Name} continues to lead the charge with its revolutionary technology.

Innovative Belt Solutions for the Fish and Seafood Industry

The seafood and fish industry is constantly evolving and adapting to meet the needs and demands of consumers. One of the key challenges in this industry is ensuring the efficient and safe processing of fish and seafood products. To address this challenge, a prominent company in the industry, {}, has introduced a new and innovative solution – a belt specifically designed for the fish and seafood industry.With over 30 years of experience in providing high-quality processing equipment for the food industry, {} has established itself as a leader in the field. The company is known for its commitment to innovation and continuous improvement, and the introduction of the new belt for the fish and seafood industry is a testament to this commitment.The new belt is designed to address the unique requirements of processing fish and seafood products. It is made from high-quality, food-grade materials that are resistant to the harsh conditions of seafood processing, such as saltwater exposure and low temperatures. The belt is also designed to be easy to clean and maintain, ensuring that it meets the strict hygiene standards of the industry.In addition to its durability and hygiene, the belt is also designed for efficiency. It is engineered to minimize product damage and loss during the processing, ensuring that the final products are of the highest quality. The belt is also designed to be compatible with a wide range of processing equipment, making it a versatile solution for seafood processing facilities of all sizes.The introduction of this new belt is expected to have a significant impact on the fish and seafood industry. By providing a reliable and efficient solution for processing seafood products, {} is helping to streamline the production process and improve the overall quality of fish and seafood products.The company’s commitment to innovation and continuous improvement is also evident in its approach to customer service. With a team of experienced professionals, {} is dedicated to providing comprehensive support and assistance to its customers. The company works closely with seafood processing facilities to understand their specific needs and challenges, and to provide tailored solutions that meet their requirements.In addition to its focus on product quality and customer service, {} is also dedicated to sustainability and environmental responsibility. The company strives to minimize its environmental impact through the use of energy-efficient manufacturing processes and the development of eco-friendly products. The new belt for the fish and seafood industry is no exception, as it is designed to be durable and long-lasting, reducing the need for frequent replacements and minimizing waste.The introduction of the new belt for the fish and seafood industry is a testament to {}’s ongoing commitment to innovation, quality, and sustainability. By providing a reliable and efficient solution for seafood processing, {} is helping to drive the evolution of the fish and seafood industry, ensuring that consumers have access to high-quality and sustainable seafood products.In conclusion, the introduction of the new belt for the fish and seafood industry by {} is a significant development that is expected to have a positive impact on the industry. With its focus on durability, efficiency, and sustainability, the belt is a testament to the company’s commitment to providing innovative solutions that meet the needs of the seafood processing industry. As the industry continues to evolve, {} is well-positioned to remain a leader in providing high-quality processing equipment for the fish and seafood industry.

Discover the Versatility of Rectangular Tube Inserts: Enhance Furniture and More

Title: Innovations in Rectangular Tube Inserts Revolutionize Construction and Manufacturing IndustriesIntroduction: In a world driven by technological advancements, Rectangular Tube Inserts have emerged as a pioneering solution for the construction and manufacturing sectors. These versatile components play a crucial role in optimizing functionality, safety, and longevity of various products and structures. As the demand for efficient and cost-effective solutions continues to rise, companies like [Company Name] are leading the innovation in this space, providing high-quality Rectangular Tube Inserts that are revolutionizing multiple industries.[Company Name]'s Commitment to Excellence:[Company Name] is a leading manufacturer and supplier of Rectangular Tube Inserts, specializing in the production of innovative components that cater to the specific needs of diverse markets. With a rich history of over [X] years, the company has consistently demonstrated its commitment to excellence through cutting-edge research, development, and production processes.The company prides itself on maintaining stringent quality control measures, ensuring that every Rectangular Tube Insert produced adheres to industry standards and regulations. By leveraging the expertise of a dedicated team of engineers and technicians, [Company Name] continually strives to deliver reliable and top-notch products that exceed customer expectations.Industry Transformation through Rectangular Tube Inserts:1. Construction Sector:The construction industry has witnessed significant improvements with the integration of Rectangular Tube Inserts into structural designs. These inserts enhance stability, mitigate vibrations, and improve load-bearing capacity. By providing additional support and reinforcement, they enable architects and engineers to create innovative structures that can better withstand external forces. Whether it's skyscrapers, bridges, or residential buildings, Rectangular Tube Inserts are becoming essential components in the construction of robust and durable structures.2. Manufacturing Sector:In the manufacturing sector, Rectangular Tube Inserts have revolutionized assembly and integration processes across various industries. By securely fitting into hollow tubes and frames, these inserts facilitate the easy and precise joining of components, leading to accelerated production timelines and improved product quality. Consequently, manufacturers can streamline their operations, reduce costs, and enhance overall efficiency, ultimately resulting in increased customer satisfaction.3. Furniture and Interior Design:The furniture and interior design industries have also found immense value in Rectangular Tube Inserts. These inserts not only provide stability but also protect floors and delicate surfaces from scratches or damage caused by furniture movement. Moreover, Rectangular Tube Inserts offer aesthetic appeal by seamlessly integrating into the overall design, providing a visually pleasing finish.Environmental Considerations and Sustainable Practices:Recognizing the global call for sustainability, companies like [Company Name] remain committed to incorporating eco-friendly practices into their manufacturing processes. By utilizing recyclable materials and implementing efficient waste management systems, they contribute towards reducing environmental impact while ensuring the preservation of natural resources. This commitment aligns with the growing demand for sustainable solutions and positions Rectangular Tube Inserts as a socially responsible choice for customers.Conclusion:The advancements in Rectangular Tube Inserts have opened new avenues for innovation, enabling significant improvements in the construction, manufacturing, furniture, and interior design sectors. Manufacturers like [Company Name] have played a vital role in revolutionizing these industries by delivering high-quality and reliable inserts that enhance the overall functionality, safety, and durability of various products and structures. They continue to strive for excellence, providing customers with cutting-edge solutions that meet and exceed their requirements. As the industry evolves and embraces technological progress, Rectangular Tube Inserts are poised to pave the way for future advancements and transform the way we build and manufacture our world.

Ultimate Guide to Choosing the Best Aluminum Profile for Your Project

Aluminum Profile Industry Booming: A Closer Look at [Company Name]The aluminum profile industry is experiencing a rapid growth spurt, driven by the increasing demand for lightweight and durable materials in various sectors such as construction, automotive, and aerospace. [Company Name], a leading player in the aluminum profile market, is at the forefront of this industry boom, delivering high-quality products and innovative solutions to meet the evolving needs of its customers.[Company Name], with its decades of experience and expertise in aluminum profile manufacturing, has positioned itself as a key contributor to the industry's growth. The company's state-of-the-art production facilities and advanced technologies enable it to produce a wide range of aluminum profiles that are renowned for their exceptional strength, corrosion resistance, and versatility.Speaking about the growth of the aluminum profile industry, [Company Name]'s CEO expressed optimism about the opportunities ahead. "The demand for aluminum profiles is on the rise, driven by the need for sustainable and cost-effective solutions across various industries. As a company committed to excellence, we are well-positioned to capitalize on this trend and continue to deliver superior products and services to our clients."In the construction sector, the use of aluminum profiles has gained traction due to their remarkable lightweight properties and tough durability. Architects and builders are increasingly turning to aluminum profiles for their projects, citing their aesthetic appeal and sustainability as key factors in their decision-making process. [Company Name] has been a trusted partner for many construction companies, providing them with customized aluminum profiles that meet their specific project requirements.Moreover, the automotive industry has also embraced the use of aluminum profiles, driven by the need to reduce vehicle weight and improve fuel efficiency. As automakers look for ways to enhance the performance of their vehicles, the demand for lightweight and sturdy materials like aluminum profiles is on the rise. [Company Name], with its extensive experience in serving the automotive sector, has developed a range of aluminum profiles that meet the stringent quality and performance standards of this industry.Additionally, the aerospace industry has also recognized the value of aluminum profiles, leveraging their exceptional strength-to-weight ratio for aircraft construction and components. With the increasing demand for fuel-efficient and cost-effective air travel, the aerospace sector is investing in advanced materials like aluminum profiles to drive innovation and improve overall aircraft performance. [Company Name] is at the forefront of this technological advancement, partnering with aerospace manufacturers to supply them with high-quality aluminum profiles for their critical applications.[Company Name]'s commitment to sustainability and environmental responsibility is also evident in its aluminum profile manufacturing process. The company has implemented eco-friendly practices and invested in efficient resource utilization to minimize its environmental footprint. Through its sustainable approach to production, [Company Name] not only delivers top-notch aluminum profiles but also contributes to a greener and more sustainable future.Looking ahead, [Company Name] is poised to capitalize on the growing demand for aluminum profiles and expand its market reach with innovative products and solutions. With a strong focus on research and development, the company is continuously striving to enhance its product offerings and meet the evolving needs of its customers across various industries.In conclusion, the aluminum profile industry is experiencing a significant boom, driven by the increasing demand for lightweight, durable, and sustainable materials. [Company Name], with its unwavering commitment to excellence and innovation, is well-positioned to capitalize on this growth and continue to be a leading player in the industry. As the company looks to the future, it remains dedicated to delivering superior products and solutions that meet the diverse needs of its customers while contributing to a more sustainable and prosperous world.

High-Quality Aluminum Extrusion Profiles at Standard Sizes for Various Applications

Standard Aluminum Extrusion Profiles – the Key to Higher Efficiency and ProductivityAluminum extrusion is a crucial process in various industries, including construction, automotive, aerospace, and electronics. The demand for standard aluminum extrusion profiles has been on the rise due to their numerous benefits, including lightweight, high strength, and corrosion resistance. Companies around the world are constantly seeking efficient and high-quality aluminum extrusion solutions to meet their production needs.As a leading manufacturer of aluminum extrusion profiles, {} has been at the forefront of providing innovative and reliable solutions for a wide range of industries. With a strong emphasis on quality, precision, and customization, {} has become a trusted partner for businesses looking to improve their manufacturing processes.Standard aluminum extrusion profiles play a pivotal role in the production of various components and products. From simple shapes to complex designs, {} offers a diverse range of standard aluminum extrusion profiles to meet the specific needs of its customers. Whether it's for framing systems, heat sinks, or structural components, {} has the expertise and capabilities to deliver top-quality aluminum extrusion profiles that meet the highest industry standards.In addition to its extensive product range, {} is committed to providing a seamless and efficient experience for its customers. The company's state-of-the-art manufacturing facilities, combined with advanced technology and a highly skilled workforce, enable {} to offer quick turnaround times and competitive pricing without compromising on quality.One of the key advantages of standard aluminum extrusion profiles is their ability to streamline the manufacturing process. By using standard profiles, businesses can save time and costs associated with custom tooling and design. Standard aluminum extrusion profiles allow for greater efficiency and productivity, as they can be readily used in various applications without the need for extensive modifications or adjustments.Moreover, standard aluminum extrusion profiles offer a high degree of design flexibility, making them suitable for a wide range of applications. Whether it's for prototyping, small-scale production, or large-scale manufacturing, {} can provide standard aluminum extrusion profiles that meet the exact specifications and requirements of its customers. With the ability to extrude complex shapes and profiles, {} ensures that its standard aluminum extrusion profiles are versatile and adaptable to different production needs.Furthermore, standard aluminum extrusion profiles offer exceptional structural integrity and durability, making them ideal for demanding applications. {} is dedicated to maintaining the highest standards of quality and performance, ensuring that its standard aluminum extrusion profiles are capable of withstanding the harshest operating conditions and environments. By choosing {} as their preferred supplier, businesses can rely on the durability and longevity of standard aluminum extrusion profiles for their critical operations.With a relentless focus on innovation and continuous improvement, {} remains committed to staying ahead of the curve in the aluminum extrusion industry. The company continually invests in research and development to enhance its product offerings and manufacturing processes, ensuring that its standard aluminum extrusion profiles meet the evolving needs of the market.In conclusion, standard aluminum extrusion profiles are essential for businesses looking to enhance their manufacturing efficiency and productivity. As a leading manufacturer of aluminum extrusion profiles, {} offers a comprehensive range of standard profiles that are engineered to deliver superior performance and reliability. With a strong emphasis on quality, customization, and innovation, {} is well-positioned to meet the diverse needs of industries seeking top-quality standard aluminum extrusion profiles. By choosing {} as their trusted partner, businesses can achieve higher efficiency and productivity in their production processes, ultimately driving their success in today's competitive marketplace.

Innovative Spiral Conveyor Technology Revolutionizing Material Handling

Title: Pioneering Shaftless Spiral Conveyor Revolutionizes Material HandlingIntroduction:In an era demanding efficient and sustainable solutions specific to material handling, companies are constantly seeking innovative technologies to streamline their operations. One such ground-breaking solution, the Shaftless Spiral Conveyor, has emerged as a game-changer in the industry. This remarkable piece of machinery, developed by a renowned manufacturer (brand name removed), eliminates many of the challenges associated with traditional conveyors, offering enhanced performance, flexibility, and cost-effectiveness.Company Background:The manufacturer behind the innovative Shaftless Spiral Conveyor is a global leader in conveyor manufacturing and has been at the forefront of pioneering solutions for over three decades. Renowned for its commitment to excellence and continuous improvement, the company prides itself on delivering cutting-edge technologies that redefine material handling processes across various industries.Incorporating state-of-the-art innovation and extensive research and development, the manufacturer has developed the Shaftless Spiral Conveyor to address the limitations of traditional conveyors. This solution offers significant advantages over its counterparts, making it an attractive option for businesses across a broad spectrum of sectors.Enhanced Performance:Traditional conveyors often face challenges when handling sticky, viscous, or difficult-to-transport materials. With a design that eliminates the need for a center pipe, the Shaftless Spiral Conveyor ensures smooth and efficient transportation of such materials. This innovative feature prevents jamming, clogging, or material build-up, reducing downtime and increasing overall productivity.In addition, the adaptable design allows for multi-directional movement, enabling the conveyor to navigate around obstacles or fit into tight spaces with ease. This increased flexibility improves overall operational efficiency and optimizes workflow, making it an ideal solution for industries characterized by complex material handling requirements.Flexibility for Variable Applications:The Shaftless Spiral Conveyor lends itself to a wide range of applications due to its adaptability. Whether it is transferring bulk materials, sludge, waste, or recyclables, this solution ensures seamless integration into existing material handling systems. The conveyor's gentle handling capabilities also minimize the likelihood of material degradation or deterioration, ensuring the integrity of sensitive or fragile goods.Furthermore, the easily customizable design allows for specific system configurations, enabling businesses to tailor the conveyor to their unique needs. The absence of a central core provides additional flexibility, allowing for easy maintenance, cleaning, and rapid material changeover, saving time and reducing operational costs.Cost-Effectiveness and Sustainability:In today's business landscape, sustainability and cost-effectiveness are paramount considerations. The Shaftless Spiral Conveyor aligns with these objectives by offering reduced power consumption and lower maintenance requirements, resulting in decreased operational costs. Its innovative design minimizes wear and tear, extending the lifespan of components and reducing the need for frequent replacements.Moreover, the solution's compatibility with advanced automation technologies enables businesses to automate their material handling processes. This integration enhances operational efficiency, reduces labor costs, and contributes to a greener future by minimizing human intervention and decreasing the overall carbon footprint of the organization.Conclusion:As industry demands continue to evolve, the need for innovative material handling solutions becomes increasingly crucial. The Shaftless Spiral Conveyor, developed by a leading conveyor manufacturer, offers a pioneering approach to address the challenges faced by businesses in this realm. With enhanced performance, flexibility, and cost-effectiveness, this cutting-edge solution is set to revolutionize material handling across a variety of industries. By eliminating traditional constraints and incorporating sustainable practices, the Shaftless Spiral Conveyor represents a vital step forward in optimizing operations and meeting the evolving needs of the modern business landscape.

Efficient and Automated Chicken Packing Machine Revolutionizes Poultry Industry

Innovative Chicken Packing Machine Revolutionizes Food PackagingFood packaging is a crucial aspect of the food industry. Poor packaging can result in spoilage, wastage, and other undesirable outcomes. As such, food producers are always striving to improve their packaging methods to ensure that their products remain fresh while in transit and on the shelves. In this regard, the introduction of a new chicken packing machine has made a significant contribution to the food industry.The machine, which has been designed with efficiency and ease of use in mind, has quickly become a staple in food processing plants around the world. With an intuitive interface that requires minimal training, operators can put it to work as soon as it is set up. Moreover, the machine is flexible enough to handle a wide range of products and packaging types.One of the principal benefits of this chicken packing machine is its ability to work at high speeds. This feature is particularly crucial in large-scale food production settings where time is of the essence. With the fast-paced nature of food processing plants, the speed of packaging can either be a bottleneck or an advantage. With the chicken packing machine, it is no doubt the latter.Additionally, the machine utilizes a range of safety features, including sensors that ensure that it does not malfunction or cause accidents in the workplace. The safety of food processing personnel is paramount, and this machine does not disappoint in this regard.The chicken packing machine's precision is another distinguishing factor. The machine ensures that all products are packaged in a uniform manner. This uniformity not only enhances the product's visual appeal but also ensures that all products are adequately protected during transportation and storage.The benefits that this machine offers are endless. For one, it greatly reduces production times and minimizes food waste. This translates to significant cost savings, which ultimately leads to an increase in profitability for food processing plants. The machines improve the efficiency of the production line, ensuring that the output meets the required volume while maintaining the quality of the packaged goods.It's essential to note that this chicken packing machine belongs to a company that prides itself on providing high-quality food processing and packaging equipment. The company has been in operation for several decades, continually innovating and refining its products to provide its customers with the most effective solutions.The company's R&D team spent years perfecting this chicken packing machine, and their efforts have paid off as it has become widely appreciated. The team comprises experts in fields ranging from engineering to software development, all of whom work cohesively to ensure that the final product lives up to the company's high standards.The company's commitment to providing its customers with cutting-edge technology has seen it partner with various food processors and packaging companies, all of whom attest to the quality of their products. It is no surprise, therefore, that the chicken packing machine has received high ratings and a steady stream of positive reviews from satisfied customers.In conclusion, the introduction of the chicken packing machine has revolutionized the food packaging industry. The machine's exceptional speed, precision, and flexibility have made it the go-to equipment in food processing plants around the world. With the company's commitment to providing quality products and the exceptional input of its R&D team, it is no doubt that the machine will continue to make significant strides in the food packaging industry.