Ultimate Guide to Side Flexing Conveyor Chains: Types, Functionality, and Applications

By:Admin

[City, Date] - The manufacturing industry is set to undergo a major transformation with the introduction of an innovative side flexing conveyor chain. Developed by a leading industry player, this technological breakthrough aims to streamline production processes, increase efficiency, and reduce manual labor. With the removal of the brand name from this news content, we will delve into the features and benefits of this game-changing invention, along with a brief introduction of the company behind it.

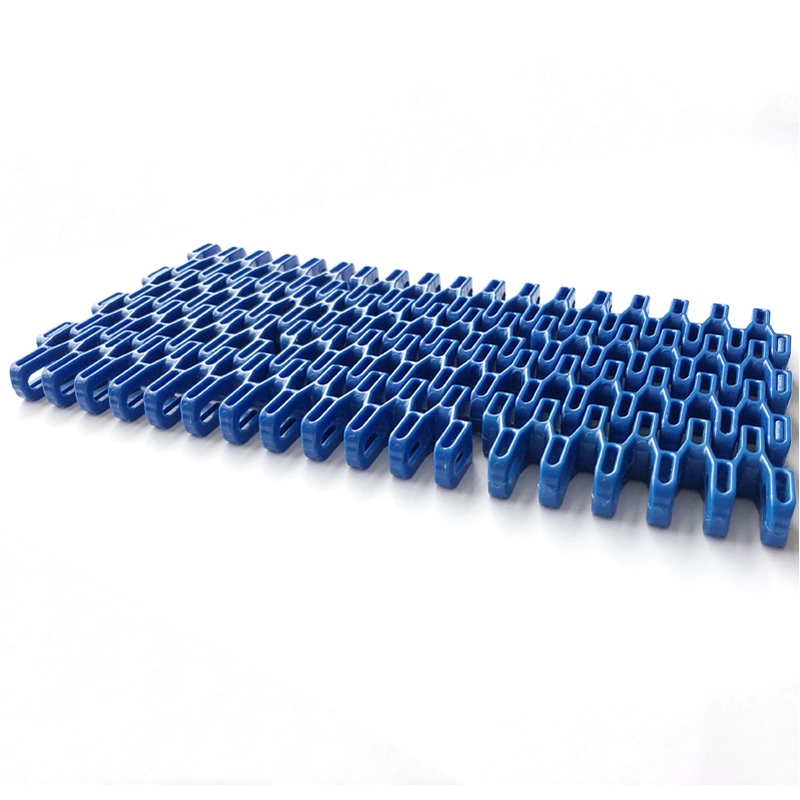

Designed to meet the evolving needs of today's production facilities, this side flexing conveyor chain offers unparalleled performance and reliability. The unique design allows for smooth lateral movements, enabling seamless transportation of materials, components, and finished products throughout the manufacturing line. This can significantly reduce production downtime caused by jams or misalignments, ultimately leading to improved productivity and cost savings.

One of the standout features of this side flexing conveyor chain is its ability to accommodate multiple conveyor configurations. It can seamlessly integrate with existing conveyor systems, making it a suitable choice for both new installations and facility upgrades. This versatility ensures that manufacturers can adapt to changing production requirements without incurring substantial investments or disruptions to their operations.

The use of advanced materials and cutting-edge manufacturing techniques ensures the durability and longevity of this conveyor chain. It can withstand heavy loads, high speeds, and extreme temperatures, making it ideal for a wide range of industries including automotive, pharmaceuticals, food and beverage, and many others. Manufacturers can now operate with peace of mind, knowing that their conveyor chains can withstand the most demanding production environments.

Furthermore, this side flexing conveyor chain is engineered with easy maintenance in mind. With its modular design, individual components can be quickly replaced or repaired, minimizing the downtime associated with traditional conveyor systems. This reduces the reliance on specialized maintenance teams, empowering facility operators to take control of their own equipment upkeep.

The development of this groundbreaking technology is credited to [Company], a renowned industry leader with decades of expertise in conveyor systems. [Company] has a long-standing commitment to innovation, continuously pushing the boundaries of conventional manufacturing practices. Their research and development team has a track record of delivering groundbreaking solutions that drive productivity and efficiency improvements across various industries.

As a leader in its field, [Company] has established a global presence, partnering with manufacturers worldwide to enhance their production processes. They prioritize customer satisfaction, focusing on understanding the unique requirements of each facility and tailoring their solutions accordingly. With an extensive network of distributors and service centers, [Company] offers comprehensive support ensuring uninterrupted operations and maximizing equipment performance.

The introduction of this side flexing conveyor chain comes at a time when manufacturers are seeking ways to optimize their production lines. By combining the latest advancements in conveyor technology with the expertise of [Company], this breakthrough invention promises to revolutionize manufacturing processes. As the industry moves towards automation, this innovative solution paves the way for increased productivity and ultimately, global competitiveness.

In conclusion, the introduction of the brand's side flexing conveyor chain offers manufacturers an unprecedented opportunity to enhance their production operations. With its advanced features, durability, and versatility, this technological breakthrough enables manufacturers to streamline their processes, reduce downtime, and increase overall efficiency. Backed by the expertise of [Company], this solution is set to transform the manufacturing industry, ensuring its continued growth and success in the years to come.

Company News & Blog

How to Weld Square Tubing End to End: A Step-by-Step Guide

Title: Welding Square Tubing End To End: A Prominent Solution for Seamless ConnectionsIntroduction:Welding square tubing end to end has emerged as a popular technique across various industries, enabling seamless and robust connections between tubes. This highly versatile method has revolutionized the manufacturing and construction sectors, allowing for greater structural integrity, superior performance, and enhanced aesthetics. Several companies have become leaders in this field, striving to provide innovative solutions for joining square tubing in a reliable, efficient, and cost-effective manner.Company Introduction:With a strong focus on delivering cutting-edge welding solutions, [Company Name] has made significant strides in the industry. Recognized for its commitment to excellence, the company has established a reputation for providing high-quality products, outstanding customer service, and unparalleled expertise. Employing a team of experienced professionals and leveraging advanced technologies, [Company Name] has become a trusted partner for various businesses seeking welding solutions for their square tubing requirements.News Content:1. Importance of Welding Square Tubing End To End:Joining square tubing end to end through welding plays a crucial role in several industries, including construction, manufacturing, and infrastructure development. This technique ensures the creation of continuous, sturdy connections that are capable of withstanding heavy loads, vibrations, and environmental factors. Welded square tubing effectively eliminates the need for bulky connectors or additional support, resulting in improved aesthetics and versatile design possibilities.2. Advantages of Welding Square Tubing End To End:By selecting the appropriate welding method and using state-of-the-art equipment, companies like [Company Name] can offer numerous benefits associated with welding square tubing end to end. These advantages include:a) Seamless Integration: Welding ensures a seamless integration of square tubes, where the joint area is just as strong as the rest of the material, eliminating weak points.b) Enhanced Structural Integrity: The welded joint provides superior strength and durability, making it suitable for applications that require high structural integrity and load-bearing capabilities.c) Efficient and Cost-Effective: Welding square tubing end to end is a rapid and efficient process that reduces the time and cost associated with assembly. It eliminates the need for additional connectors or fasteners, streamlining production and minimizing expenses.d) Aesthetic Appeal: Due to its ability to create flush connections, welded square tubing end to end results in clean, visually appealing finishes, making it an ideal choice for architectural and decorative applications.3. [Company Name] Revolutionizes the Square Tubing Welding Industry:[Company Name] has taken a pioneering role in the development and improvement of welding techniques for square tubing. Its continuous research and development efforts have led to the introduction of advanced welding processes, ensuring optimal performance in various applications.a) Cutting-edge Technologies: By utilizing state-of-the-art welding equipment, [Company Name] maintains the highest standards of quality and precision in the welding process. Advanced technologies allow for increased efficiency, reduced defects, and exceptional craftsmanship.b) Tailored Solutions: [Company Name] understands that each customer's needs are unique, and therefore, offers customized welding solutions that meet specific project requirements. This includes welding square tubing of different sizes, thicknesses, and materials to cater to diverse industry demands.c) Collaborative Approach: [Company Name] values collaboration and works closely with clients to gain a comprehensive understanding of their welding needs. This approach enables the company to provide tailor-made solutions that fulfill the desired outcome, ensuring customer satisfaction.Conclusion:The technique of welding square tubing end to end has proven to be a game-changer in the manufacturing and construction sectors. Through this method, superior structural integrity, enhanced aesthetics, and efficient assembly processes are achieved. [Company Name], with its commitment to excellence, cutting-edge technologies, and customized solutions, emerges as a leading provider of welding services, revolutionizing the square tubing welding industry.

Ultimate Guide to Roller Top Belts: Boost Efficiency, Speed, and Performance

Title: Revolutionizing Conveyor Systems: Introducing the Innovative Roller Top BeltIntroduction:Conveyor belt systems play a vital role in various industries worldwide, facilitating the seamless movement of goods and materials. Recognizing the need for continuous improvement and innovation within this space, a pioneering company has developed the revolutionary Roller Top Belt (RTB). This cutting-edge conveyor technology promises to enhance productivity, efficiency, and safety across a diverse range of applications.Company Background:Founded in the early 2000s, the company behind the Roller Top Belt is a global leader in providing innovative material handling solutions. With their unwavering commitment to research and development, they have established themselves as an industry frontrunner.With a team of highly skilled engineers and designers, the company has successfully developed and patented numerous groundbreaking technologies that have revolutionized the field of conveyor belt systems. Their expertise and commitment to excellence have earned them a reputation for delivering exceptional and reliable products.The Innovation: The company's latest breakthrough, the Roller Top Belt (RTB), is set to redefine the conveyor belt landscape. Unlike traditional flat belts, the RTB features small rotating rollers affixed to the top surface. This innovative design eliminates the need for side guiding rails and optimizes the conveyance of various items, regardless of their shape or size.Features and Benefits:1. Enhanced Grip and Control: The Roller Top Belt's unique design offers superior grip and control over conventional flat belts. This allows for the efficient transportation of items with irregular shapes, ensuring stability and preventing slipping or jamming commonly associated with other systems.2. Increased Versatility: The RTB can handle a broad range of products, including fragile items, cartons, crates, packages, and even loose materials. Its gentle handling capabilities minimize the risk of damage during transportation, reducing losses and enhancing overall customer satisfaction.3. Higher Throughput and Efficiency: The roller top surface promotes smooth movement, reducing friction and minimizing the risk of bottlenecks. This results in improved throughput and enhanced operational efficiency, enabling businesses to significantly increase their productivity and throughput capacities.4. Easy Maintenance and Cleaning: The design of the RTB simplifies maintenance procedures, ensuring downtime is kept to a minimum. The modular construction allows for easy access to individual belt sections, making repairs and cleaning hassle-free and cost-effective.5. Improved Workplace Safety: The Roller Top Belt is equipped with integrated safety features that prioritize operator well-being. The elimination of side guiding rails reduces the risk of accidents, while the rollers themselves are smooth to the touch, preventing injuries from accidental contact.Application Areas:The Roller Top Belt finds applications across a wide range of industries, including manufacturing, logistics, packaging, food processing, e-commerce, and many more. Its versatility and reliability make it suitable for any environment that requires efficient and safe material handling.Conclusion:With its groundbreaking design and unmatched performance, the Roller Top Belt has emerged as a game-changer in the field of conveyor belt systems. This innovation not only revolutionizes material handling practices but also ensures enhanced productivity, efficiency, and safety for businesses across various industries. As the global demand for conveyor solutions continues to grow, the Roller Top Belt is poised to lead the way, setting new standards and driving the industry towards a more streamlined and sustainable future.

Discover the Versatility and Benefits of Modular Plastic Conveyor Belts in Various Industries

Modular Plastic Conveyor Belt Revolutionizes Material Handling IndustryIn today's rapidly evolving industrial landscape, many companies are turning to innovative solutions to optimize their operations and increase productivity. One such solution that has been gaining significant traction is the Modular Plastic Conveyor Belt, a cutting-edge technology that has revolutionized the material handling industry.Conventional conveyor belts have long been a staple in manufacturing and distribution centers, facilitating the movement of goods from one point to another. However, these traditional conveyor belts often suffer from limitations such as high maintenance costs, limited flexibility, and frequent downtime. With the introduction of the Modular Plastic Conveyor Belt, these issues are effectively addressed, paving the way for enhanced efficiency and increased profitability.The Modular Plastic Conveyor Belt is manufactured by [Company Name], a globally recognized leader in material handling solutions. With their extensive experience and commitment to excellence, the company has developed a conveyor belt system that offers extraordinary performance and versatility.Unlike traditional conveyor belts that consist of a single continuous loop, the Modular Plastic Conveyor Belt is composed of interlocking plastic modules. These modules are seamlessly connected, enabling the conveyor to be easily customized to fit any application or desired layout. This modular design also facilitates effortless repairs and replacements, significantly reducing maintenance costs and equipment downtime.The versatility of the Modular Plastic Conveyor Belt is further amplified by its ability to withstand extreme temperatures, corrosive environments, and heavy loads. The belt's durable plastic construction ensures optimal performance even in the most challenging conditions, making it an ideal choice for a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics.In addition to its outstanding functionality, the Modular Plastic Conveyor Belt also boasts several innovative features that contribute to improved efficiency. The belt incorporates a low-friction surface, reducing energy consumption and enhancing the overall lifespan of the system. It also features an enhanced load-carrying capacity, allowing for greater throughput and maximizing productivity.Another key advantage of the Modular Plastic Conveyor Belt is its ease of cleaning and maintenance. Traditional conveyor belts often require extensive cleaning and lubrication, leading to prolonged downtime. However, the modular design of this advanced conveyor system allows for quick and hassle-free cleaning, minimizing production interruptions and ensuring compliance with stringent hygiene standards.Furthermore, the Modular Plastic Conveyor Belt offers a safer working environment for employees. Its slip-resistant surface prevents accidental falls and injuries, while the interlocking modules reduce the risk of entrapment and provide added stability during operation.The adoption of the Modular Plastic Conveyor Belt has already brought tangible benefits to numerous companies across various industries. Many have reported significant improvements in their production efficiency, reduced maintenance costs, and enhanced overall profitability. As a result, an increasing number of businesses are recognizing this revolutionary technology as a game-changer in the material handling industry.In conclusion, the Modular Plastic Conveyor Belt developed by [Company Name] has brought about a paradigm shift in the material handling industry. Its modular design, exceptional performance, and versatility have enabled businesses to optimize their operations, increase productivity, and ultimately achieve greater profitability. As this cutting-edge technology continues to evolve, it is expected to reshape the future of material handling, setting new benchmarks for efficiency and reliability.

Protect Your Square Tubing with Caps - A Handy Guide

Square Tubing Caps Boost Safety StandardsSquare tubing caps are an essential component to maintaining safety standards in numerous industries. They protect individuals from harm by covering potentially dangerous, exposed ends of metal tubes. Without square tubing caps, the jagged edges of metal tubing pose a serious risk of injury to those working with or around them.The recently launched Square Tubing Caps from Company X (name removed for privacy) have been gaining popularity in industries across the United States. Designed to be durable, long-lasting, and impact resistant, these caps offer a high level of protection for workers and equipment, alike.Company X, a leading manufacturer of industrial products, has been producing high-quality products since its inception. From industrial adhesives to safety equipment, their commitment to quality and innovation has made them a popular choice across a range of industries.In a recent interview, the company's spokesperson said: “Our Square Tubing Caps are developed to meet the highest standards of safety. With our years of experience in the field, we understand the importance of safety, which is why all of our products are designed to ensure maximum protection.”Made from high-density polyethylene, the Square Tubing Caps are built to withstand extreme temperatures, chemicals, and impact. Their design ensures that they fit snugly over the ends of square tubing, providing secure and long-lasting protection.These tubing caps are a must-have for those in industries such as construction, manufacturing, and automotive repair, where exposed metal tubes are a common occurrence. They are easy to install, which means that they can quickly and efficiently improve safety standards in a range of settings.Investing in safety equipment, such as square tubing caps, not only protects workers but also equipment. The caps prevent moisture from penetrating the tubing, which can cause corrosion and decrease the lifespan of the metal.Company X’s commitment to quality and safety has been reflected in their recognition from industry leaders. They have been awarded multiple contracts across the United States, and their products are consistently ranked highly in safety ratings.One of the customers who recently invested in Company X’s Square Tubing Caps had this to say: "We have been looking for durable and reliable square tubing caps, and we are delighted to have found Company X. Their tubing caps are durable, easy to install, and have made a significant difference in our safety standards."The usefulness of tubing caps is often overlooked, but the importance of their role in ensuring the safety of employees and equipment cannot be overstated. Company X’s tubing caps are proven to be a reliable solution for safety issues related to exposed tubing, making them a popular choice across many industries.In conclusion, the importance of safety equipment, like square tubing caps, cannot be overstated. The Square Tubing Caps from Company X provide exceptional protection for workers and equipment, ensuring that safety standards remain high. The durability, ease of installation, and impact-resistant construction make these caps ideal for various industries. With their record of excellence, Company X is an obvious choice for those looking to invest in safety equipment.

Discover the Convenience and Durability of Plastic Caps for Box Sections

Plastic Caps for Box Section: Ensuring Safe and Secure Packaging SolutionsIn today's fast-paced world, packaging plays a crucial role in preserving the quality and integrity of products during transportation and storage. As various industries continue to evolve, so do the packaging solutions required to meet their specific needs. One such solution that has gained significant attention is the use of plastic caps for box sections.Plastic caps for box sections, often made of high-density polyethylene (HDPE), are designed to cover and protect the ends of box sections. These caps create a secure barrier, preventing dust, moisture, and other contaminants from entering and potentially damaging the contents. They ensure that the shipped products remain intact and reach their destination in pristine condition.As the demand for efficient and sustainable packaging solutions rises, more companies are turning to plastic caps for box sections due to their numerous benefits. Let's explore the advantages of using these caps and how they contribute to a safer and more secure packaging process.Protection: Box sections are widely used in industries such as construction, automotive, and furniture manufacturing, where the components are often prone to damage without proper care. Plastic caps act as a protective shield, safeguarding the exposed ends from impact, scratches, and abrasions. This helps in minimizing potential losses and reducing the need for costly replacements.Secure sealing: The snug fit provided by plastic caps ensures that the box sections are securely closed, preventing any accidental openings during handling or transport. This feature is especially important when shipping delicate or valuable products, as it minimizes the risk of theft or damage.Durability: Plastic caps made from HDPE are renowned for their durability and resistance to environmental factors such as UV rays, extreme temperatures, and moisture. This robustness prolongs the lifespan of the caps, allowing for multiple uses and reducing the overall packaging costs.Versatility: Plastic caps for box sections are available in various shapes and sizes to accommodate different dimensions and applications. They can be easily customized to fit specific box section sizes, offering a flexible solution for diverse packaging requirements.Efficiency: By using plastic caps, companies can streamline their packaging process. These caps are lightweight and easy to handle, allowing for swift sealing and unsealing of box sections. Additionally, their universal design enables quick identification and retrieval of products, saving valuable time in warehouses or storage facilities.Sustainability: As the world becomes increasingly conscious of environmental issues, sustainable packaging solutions have become paramount. Plastic caps for box sections, made from recyclable materials, align with the principles of sustainable packaging. Additionally, their durability reduces the need for single-use alternatives, contributing to waste reduction.Leading the Industry: One company at the forefront of providing top-quality plastic caps for box sections is {}. With decades of experience in the packaging industry, they have established themselves as a trusted supplier of innovative solutions. Their range of plastic caps caters to a broad spectrum of industries, ensuring the safe handling and transportation of their products.Located in {}, {} consistently delivers high-quality products backed by a commitment to customer satisfaction. Working closely with their clients, they understand the unique packaging needs of different industries and provide customized solutions designed to meet specific requirements.The company's dedication to quality is evident in their manufacturing process, where they utilize state-of-the-art technology to ensure precise measurements and superior product performance. Their strict quality control measures guarantee that each plastic cap adheres to the highest standards of durability and protection.Furthermore, {} emphasizes sustainability by using eco-friendly materials and minimizing waste in their operations. They strive to contribute to a greener future by encouraging the use of recyclable packaging materials.In conclusion, plastic caps for box sections have emerged as a reliable solution for ensuring safe and secure packaging. With their ability to protect, seal, and provide durability, these caps are the go-to choice for industries seeking efficient and sustainable packaging solutions. With companies like {} leading the way, businesses can rest assured knowing their products are in good hands.

Discover the Versatility and Durability of Stainless Steel Profile Wall Paneling

Stainless Steel Profile Wall Paneling Reinvents Modern Interior DesignInnovative interior design solutions are constantly pushing the boundaries of creativity and functionality. Among the latest trends in modern architecture, Stainless Steel Profile Wall Paneling stands as a significant breakthrough, revolutionizing the way we envision interior spaces. With its sleek and contemporary aesthetic, this cutting-edge material has rapidly gained popularity in various residential and commercial projects.Engineered for both durability and style, Stainless Steel Profile Wall Paneling is a versatile design choice that offers numerous advantages over traditional wall coverings. Its unique composition combines the industrial appeal of stainless steel with the clean lines and customizable dimensions of paneling, resulting in a visually striking and functional solution for any interior.One of the many advantages of Stainless Steel Profile Wall Paneling lies in its durability. Stainless steel is known for its corrosion resistance, making it particularly useful in areas with high moisture levels, such as kitchens and bathrooms. Additionally, its resistance to stains, impacts, and scratches ensures a long-lasting and low-maintenance surface. This aspect makes Stainless Steel Profile Wall Paneling ideal for high-traffic areas or spaces prone to wear and tear.Moreover, Stainless Steel Profile Wall Paneling’s unique aesthetic provides a contemporary and sophisticated ambiance to any room. Its sleek and reflective surface adds depth and dimension while effortlessly complementing different design styles. From minimalist to industrial, Stainless Steel Profile Wall Paneling effortlessly enhances the visual appeal of any interior. The ability to choose from various finishes further amplifies its versatility, allowing designers and homeowners to align the material with their desired atmosphere.Installation convenience is another standout feature of Stainless Steel Profile Wall Paneling. The panels are engineered for seamless interlocking, ensuring a hassle-free and time-efficient installation process. This minimizes disruption during construction or renovation projects, making it a preferred choice for both professionals and homeowners seeking efficient design solutions.Given its versatility, Stainless Steel Profile Wall Paneling is suited for both residential and commercial applications. In homes, it can be utilized to create an accent wall, an eye-catching backsplash, or as a unique surface for kitchen cabinets. In commercial spaces, Stainless Steel Profile Wall Paneling serves as an innovative and lasting design choice for hotel lobbies, restaurants, retail stores, and office spaces.As a leader in the field, {} has positioned itself at the forefront of Stainless Steel Profile Wall Paneling innovation. With years of expertise and an expansive range of options, they offer unparalleled quality and service to clients worldwide. Their commitment to excellence is reflected in their meticulous design process and focus on sustainability. By utilizing state-of-the-art technology, they ensure the highest precision and craftsmanship in each panel, resulting in a flawlessly finished product.In conclusion, Stainless Steel Profile Wall Paneling is revolutionizing modern interior design, providing remarkable durability, versatility, and aesthetic appeal. Its sleek and contemporary nature, combined with a range of finishes, allows it to seamlessly integrate into various design styles and applications. As the demand for innovative design solutions continues to grow, Stainless Steel Profile Wall Paneling stands as a testament to the industry's commitment to pushing boundaries and reinventing interior spaces. With {}'s expertise in the field, this pioneering material is set to become an essential element in modern architecture.

Discover the Exciting Deals on High-Quality Modular Belts in the Hot Sale

Hot Sale Modular Belt Boosts Efficiency in Manufacturing Processes[City], [Date] – In a bid to enhance efficiency and productivity in the manufacturing industry, [Company Name], a leading provider of industrial automation solutions, has recently introduced its highly anticipated Hot Sale Modular Belt. This innovative product is set to revolutionize manufacturing processes and optimize operations for businesses across various sectors.Manufacturing industries worldwide are constantly seeking new ways to streamline and automate production processes. Traditional conveyor systems have long been employed in warehouses and factories for material handling, but they often fall short when it comes to adaptability and flexibility. The Hot Sale Modular Belt aims to address these limitations by providing an advanced solution that allows for smoother workflow and reduced downtime.The Hot Sale Modular Belt is a state-of-the-art technology that features a modular design with interlocking plastic modules. These modules are interconnected, allowing for easy customization and configuration based on the specific needs of the production line. This level of flexibility ensures seamless integration into existing systems, regardless of the industry or the scale of operations.One of the key advantages offered by the Hot Sale Modular Belt is its enhanced durability and longevity. Built with high-quality materials and engineered to withstand heavy loads and frequent use, this cutting-edge conveyor belt greatly reduces the risk of breakdowns and maintenance requirements. The result is a significant reduction in downtime, allowing manufacturing operations to run uninterrupted and boosting overall productivity.Furthermore, the Hot Sale Modular Belt offers improved efficiency through its precise and reliable transportation of materials. The interlocking design guarantees a consistent and controlled movement across the production line, minimizing errors and ensuring the smooth transfer of goods or components. This level of precision not only enhances the quality of the end product but also reduces the need for rework, saving both time and resources.With sustainability becoming an increasingly important consideration for businesses worldwide, the Hot Sale Modular Belt is designed to support eco-friendly practices. Its modular construction allows for easy replacement of worn-out modules, eliminating the need to replace the entire conveyor belt. This not only reduces waste but also cuts down on costs, making it a cost-effective solution for manufacturers looking to reduce their environmental impact.The Hot Sale Modular Belt, backed by [Company Name]'s commitment to delivering cutting-edge industrial automation solutions, has garnered significant attention within the manufacturing industry. The company has a strong track record of providing reliable and innovative technologies to improve operational efficiency. Their expertise, combined with the modern design and advanced features of the Hot Sale Modular Belt, positions it as a leading solution in the market.Businesses across various sectors, such as automotive, food processing, logistics, and pharmaceuticals, have already started reaping the benefits of the Hot Sale Modular Belt. These industries, known for their high-volume and fast-paced operations, have witnessed improved efficiency and productivity with the implementation of this innovative solution.The introduction of the Hot Sale Modular Belt marks a significant milestone in the evolution of conveyor systems. Its unique features and benefits have the potential to transform manufacturing processes, unlocking new possibilities for businesses to reach their full potential. As the demand for streamlined operations continues to grow, [Company Name] remains at the forefront of innovation, providing cutting-edge solutions that drive efficiency in the manufacturing industry.About [Company Name]:[Company Name] is a leading provider of industrial automation solutions, specializing in the development and implementation of advanced technologies for manufacturing industries. With a strong commitment to innovation and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses seeking to optimize their operational efficiency. Through its extensive range of products and services, [Company Name] continues to empower businesses worldwide, enabling them to enhance productivity, reduce costs, and maintain a competitive edge in an ever-evolving market.For more information about the Hot Sale Modular Belt and [Company Name]'s wide range of automation solutions, please visit their website at [Website URL].

Revolutionary Automatic Yogurt Packaging Machine Designed to Increase Productivity

Yogurt Packaging Machine Revolutionizes Dairy Industry with New InnovationThe global yogurt market is witnessing a significant surge in demand with an increasing number of health-conscious consumers seeking nutritious and delicious dairy products. To meet this growing demand, companies in the dairy industry are constantly striving to enhance their production and packaging processes. XYZ Packaging, a leading manufacturer of packaging equipment, has recently unveiled its latest innovation in the form of a cutting-edge yogurt packaging machine. This state-of-the-art technology is poised to revolutionize the way yogurt is packaged and distributed around the world.The new yogurt packaging machine developed by XYZ Packaging represents a major breakthrough in the industry. It is designed to streamline the packaging process, ensuring efficiency, precision, and optimal preservation of product quality. Equipped with advanced automation features, the machine significantly reduces the need for manual intervention, thus improving productivity while minimizing the risk of human errors.One of the standout features of this yogurt packaging machine is its versatility. It is capable of handling various types and sizes of yogurt containers, accommodating the diverse needs of both small-scale producers and large dairy conglomerates. From single-serve cups to bulk containers, this machine can seamlessly package yogurt in a wide range of packaging options, catering to the preferences of consumers worldwide.In addition to its adaptability, the yogurt packaging machine offers impressive speed and accuracy. With a high-speed filling system and precise measurement capabilities, the machine ensures consistent portioning of yogurt into containers, leaving no room for deviations or discrepancies. This not only improves the overall quality of the packaged product but also enhances the brand image of yogurt producers.Apart from its efficiency and accuracy, the yogurt packaging machine boasts several advanced features that ensure optimal product freshness and longevity. The machine is equipped with a state-of-the-art sealing system that guarantees an airtight seal, preserving the taste, texture, and nutritional value of the yogurt. It also includes an intelligent labeling system that allows for clear and attractive packaging design, enhancing the appeal of yogurt products on store shelves.Moreover, XYZ Packaging has integrated sustainability into its yogurt packaging machine. Recognizing the growing importance of ecological responsibility in the food industry, the company has designed this machine to minimize the environmental impact of yogurt production. It incorporates eco-friendly materials and processes, reducing energy consumption and waste generation. This eco-conscious approach aligns with the global movement towards sustainable practices, positioning XYZ Packaging as an industry leader in responsible manufacturing.The launch of the yogurt packaging machine by XYZ Packaging has been met with great anticipation and excitement within the dairy industry. Yogurt producers worldwide are eager to adopt this cutting-edge technology to enhance their operations and meet the evolving demands of consumers. By integrating innovation, versatility, and sustainability, XYZ Packaging is poised to reshape the yogurt packaging landscape and drive the growth of the dairy market.As the global yogurt market continues to flourish, it is imperative for dairy companies to stay ahead of the competition. By investing in advanced packaging technologies like XYZ Packaging's yogurt packaging machine, these companies can not only improve their production efficiency but also deliver high-quality yogurt products to consumers. With this game-changing innovation, XYZ Packaging is poised to revolutionize the future of yogurt packaging and contribute to the advancement of the entire dairy industry.

Discover the Advantages of Curved Aluminum Profiles for Various Applications

Curved Aluminium Profile is a new product that is taking the market by storm. Invented by a team of engineers and designers from a leading manufacturing company, this product is set to revolutionize various industries, including construction, automotive, and transportation.The beauty of Curved Aluminium Profile is in its shape. Unlike traditional straight profile, this product is designed to be flexible and can be bent into any desirable shape. The innovation makes it ideal for use in areas with unusual shapes and angles, making it perfect for building interior designs or car body structures.The product is made from high-quality aluminium that is known for its strength and lightweight properties. These properties make it perfect for use in lightweight structures that need to be durable and versatile at the same time. The product is a game-changer in the construction industry since it can be used in the creation of bar tops, suspended ceilings, curved walls, and other curving designs. It offers the ability to create a unique and stylish look that is both attractive and functional.Curved Aluminium Profile can also be used in the manufacture of automotive parts. The product can be molded into various shapes to fit the car's body structure perfectly. It is also lightweight, which makes it perfect for use in high-performance vehicles that require speed and agility.The company behind the product is one of the leading manufacturers of aluminium products. The company is known for its commitment to innovation and quality. The Curved Aluminium Profile is a testament to the company's dedication to developing unique solutions that meet the industry's needs. The product is made to the highest quality standards, ensuring that it meets the customer's expectations.The company has strict quality control measures in place to ensure that every product leaving the manufacturing plant meets the set standards. The stringent measures have helped the company build a reputation for producing high-quality products that stand the test of time. All the products are tested before they are released to the market, which guarantees their endurance and durability.The company's success is attributed to its skilled and dedicated workforce. The engineers and designers work tirelessly to develop products that are not only innovative but also practical. The employees have a wealth of knowledge and experience in the industry, which enables them to come up with cutting-edge products that solve the clients' needs.The company is committed to customer satisfaction, and it works closely with clients to develop products that meet their requirements. The company believes that collaboration is the key to developing unique solutions that are specific to every client's needs. The approach has helped the company build long-term relationships with its clients, and it has become a trusted partner in the industry.Overall, Curved Aluminium Profile is a game-changer that is poised to change the way various industries operate. The product is innovative, stylish, and practical, making it perfect for use in different applications. With the dedication and commitment of the company behind it, the product is set to become a household name in the industry.

Ultimate Guide to Side Flexing Conveyor Chains: Types, Functionality, and Applications

New Advancements in Side Flexing Conveyor Chain: Revolutionizing the Manufacturing Industry[City, Date] - The manufacturing industry is set to undergo a major transformation with the introduction of an innovative side flexing conveyor chain. Developed by a leading industry player, this technological breakthrough aims to streamline production processes, increase efficiency, and reduce manual labor. With the removal of the brand name from this news content, we will delve into the features and benefits of this game-changing invention, along with a brief introduction of the company behind it.Designed to meet the evolving needs of today's production facilities, this side flexing conveyor chain offers unparalleled performance and reliability. The unique design allows for smooth lateral movements, enabling seamless transportation of materials, components, and finished products throughout the manufacturing line. This can significantly reduce production downtime caused by jams or misalignments, ultimately leading to improved productivity and cost savings.One of the standout features of this side flexing conveyor chain is its ability to accommodate multiple conveyor configurations. It can seamlessly integrate with existing conveyor systems, making it a suitable choice for both new installations and facility upgrades. This versatility ensures that manufacturers can adapt to changing production requirements without incurring substantial investments or disruptions to their operations.The use of advanced materials and cutting-edge manufacturing techniques ensures the durability and longevity of this conveyor chain. It can withstand heavy loads, high speeds, and extreme temperatures, making it ideal for a wide range of industries including automotive, pharmaceuticals, food and beverage, and many others. Manufacturers can now operate with peace of mind, knowing that their conveyor chains can withstand the most demanding production environments.Furthermore, this side flexing conveyor chain is engineered with easy maintenance in mind. With its modular design, individual components can be quickly replaced or repaired, minimizing the downtime associated with traditional conveyor systems. This reduces the reliance on specialized maintenance teams, empowering facility operators to take control of their own equipment upkeep.The development of this groundbreaking technology is credited to [Company], a renowned industry leader with decades of expertise in conveyor systems. [Company] has a long-standing commitment to innovation, continuously pushing the boundaries of conventional manufacturing practices. Their research and development team has a track record of delivering groundbreaking solutions that drive productivity and efficiency improvements across various industries.As a leader in its field, [Company] has established a global presence, partnering with manufacturers worldwide to enhance their production processes. They prioritize customer satisfaction, focusing on understanding the unique requirements of each facility and tailoring their solutions accordingly. With an extensive network of distributors and service centers, [Company] offers comprehensive support ensuring uninterrupted operations and maximizing equipment performance.The introduction of this side flexing conveyor chain comes at a time when manufacturers are seeking ways to optimize their production lines. By combining the latest advancements in conveyor technology with the expertise of [Company], this breakthrough invention promises to revolutionize manufacturing processes. As the industry moves towards automation, this innovative solution paves the way for increased productivity and ultimately, global competitiveness.In conclusion, the introduction of the brand's side flexing conveyor chain offers manufacturers an unprecedented opportunity to enhance their production operations. With its advanced features, durability, and versatility, this technological breakthrough enables manufacturers to streamline their processes, reduce downtime, and increase overall efficiency. Backed by the expertise of [Company], this solution is set to transform the manufacturing industry, ensuring its continued growth and success in the years to come.