Tuoxin company has more than 20 years experience in this industry and we know the needs of customers, in thiscase,we developed plastic modular belts solutions. The productive efficiency can be improved if using modular plastic belt conveyor system. It can increase the height of the paper-pile and increase the production and storage in the workshop area. It can improve the transfer speed and do not need to add any other transport equipment. The paper-pile will not be out of shape or skew since the stability. So it can increase the quantity of thepaper-pile during loading,and this can decrease the transportation cost.

Tuoxin company has more than 20 years experience in this industry and we know the needs of customers, in thiscase,we developed plastic modular belts solutions. The productive efficiency can be improved if using modular plastic belt conveyor system. It can increase the height of the paper-pile and increase the production and storage in the workshop area. It can improve the transfer speed and do not need to add any other transport equipment. The paper-pile will not be out of shape or skew since the stability. So it can increase the quantity of thepaper-pile during loading,and this can decrease the transportation cost.

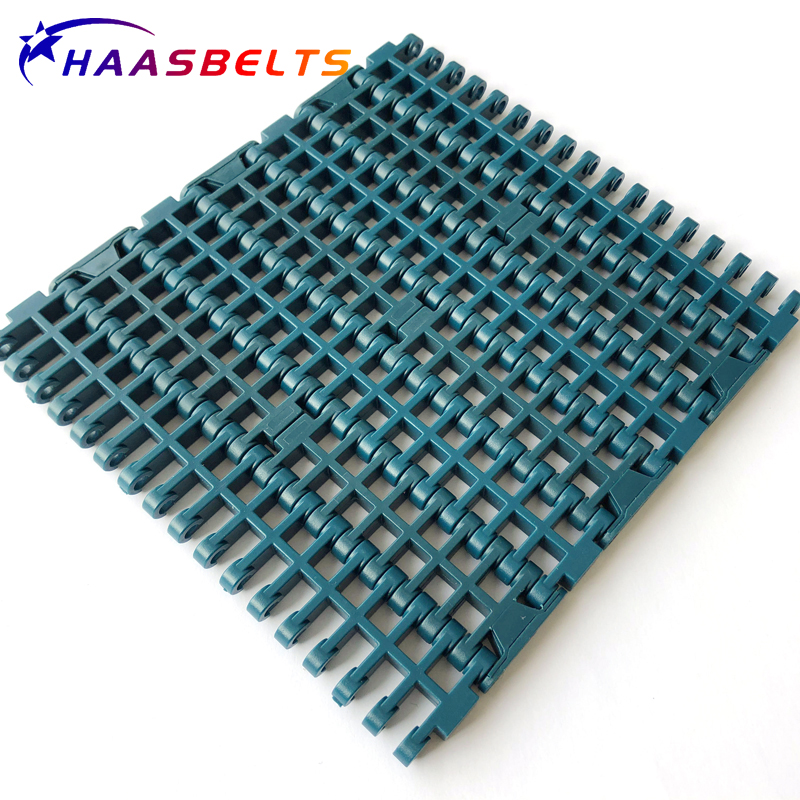

S2400 Radius Flush Grid Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W

S2400 Radius Flush Grid Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W | Belt type | Material | Temperature range℃ | Working load(max.) | Weight | Backflex radius(min.) | ||

| dry | wet | N/m(Straight) | N(Curved) | Kg/m2 | mm | ||

| TR2400 | POM | -40 to +80 | -40 to +65 | 24800 | 1100 | 7.8 | 25 |

| PP | 5 to 104 | 5 to 104 | 17500 | 780 | 5.4 | ||

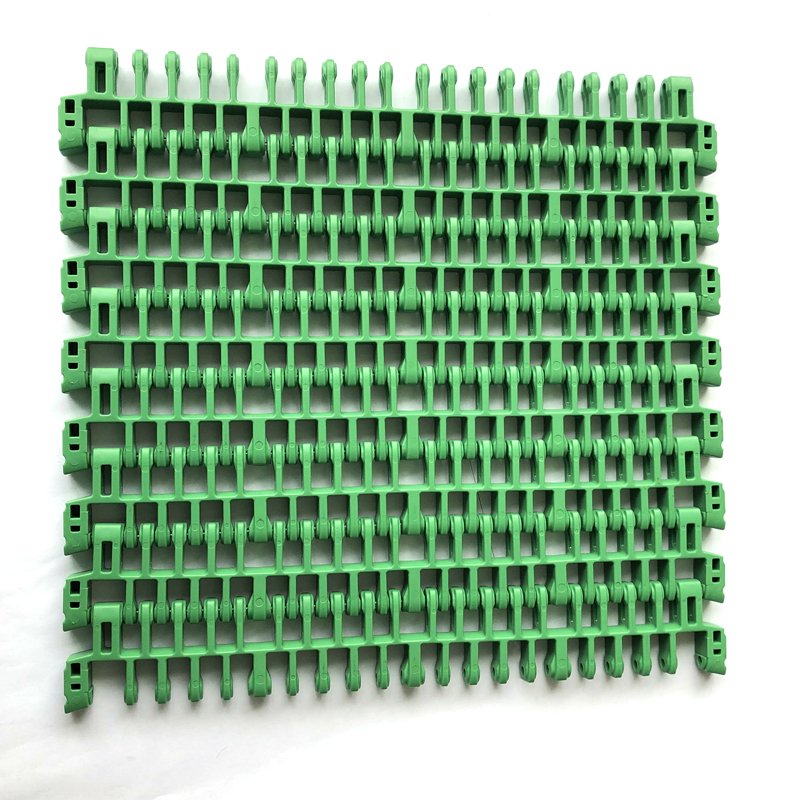

S2400 Radius Flush Grid With Hold-down Edge Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W

S2400 Radius Flush Grid With Hold-down Edge Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W | Belt type | Material | Temperature range℃ | Working load(max.) | Weight | Backflex radius(min.) | ||

| dry | wet | N/m(Straight) | N(Curved) | Kg/m2 | mm | ||

| TR2400TAB | POM | -40 to +80 | -40 to +65 | 24800 | 1100 | 7.8 | 25 |

| PP | 5 to 104 | 5 to 104 | 17500 | 780 | 5.4 | ||

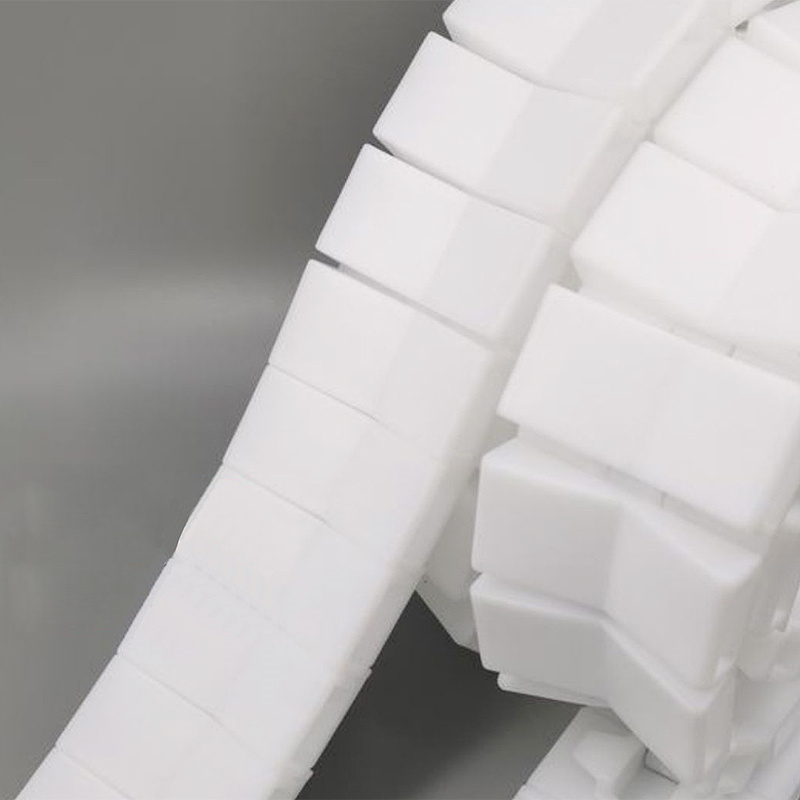

S2400 Radius Flush Grid High Deck Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W

S2400 Radius Flush Grid High Deck Belt pitch:25.4mm Open area:42% Assembling method:Connected with rods Inside turning radius: Rmin=2.2×W | Belt type | Material | Temperature range℃ | Working load(max.) | Weight | Backflex radius(min.) | ||

| dry | wet | N/m(Straight) | N(Curved) | Kg/m2 | mm | ||

| HDFG2400 | POM | -40 to +80 | -40 to +65 | 24800 | 1100 | 14.8 | 25 |

| PP | 5 to 104 | 5 to 104 | 17500 | 780 | 9.3 | ||